Plastic plumbing has come to our life for a long time and for a long time. An invariable attribute of the repair of the Soviet housing stock, along with plastic windows, became a water pipe made of poly propylene pipes.

Advantages polypropylene water pipe before steel pipes obvious:

- Cheapness and wide choose materials;

- Ease of marking and assembling the most intricate and complex options pipe layouts;

- Environmental friendliness, material resistance to corrosion and salt deposits on the walls of polypropylene communications.

Those who are faced with the tedious and time-consuming procedure for installing a water supply system from metal pipes can appreciate simple technique joining plastic using a special soldering iron for polypropylene pipes.

If the time has come to repair the apartment, the problem of replacing the water supply with plastic communications, depending on the availability of desire, money and free time, is solved:

- By hiring a craftsman and a friend who has experience with a device for soldering propylene pipes, who can help assemble marked and cut pieces with a soldering iron plastic pipes;

- Transferring the issue of turnkey repair to a team of repairmen without any desire to deal with the intricacies of assembly and soldering plastic knots;

- Doing all the work with your own hands.

The simplicity of plastic soldering assembly is so captivating that it is difficult to resist the temptation and solve the plumbing problem only by choosing and buying a soldering iron for polypropylene pipes.

The amount of money spent on the purchase of a tool will be less than the cost of the services of a master, but on the condition that you really understand how to choose a soldering iron for polypropylene pipes. In fact, a soldering iron for propylene parts and connecting fittings is a heating element with a thermomechanical or electrical system heating control and indication. Two nozzles are mounted on the heater, allowing you to simultaneously heat with a soldering iron outer surface pipes and inner surface fitting. Heating lasts an average of about 5 s, the parts are connected with a slight pressure by hand to set and form a strong connection within 2-3 s. In case of overheating or a crooked connection of parts, a part of the molten plastic may get inside the pipe, as a result, the flow area decreases.

Important ! Doing it yourself most soldering and assembly work, you are able to personally control the quality of soldering joints of polypropylene pipes.

For innovators and DIY enthusiasts, you can assemble a soldering iron for polypropylene pipes with your own hands. The strength and durability of soldering depends on the perfection of the soldering iron and how high-quality polypropylene pipes are.

What is good soldering iron assembled by hand

The principle of operation of the soldering iron is simple and uses the principle of adhesion of polypropylene parts heated to the softening temperature of the soldered surfaces. There is not always a need to rewire or resolder half of the wiring water networks in the house. Sometimes you need to work with a soldering iron for two or three connections. In this case, a home-made, do-it-yourself mini-soldering iron for polypropylene pipes from an improvised heater can help out.

For someone with experience with electrical wiring and locksmith skills to make a small amateur version of a soldering iron for polypropylene pipes is a matter of two hours.

Usually, water pipes laid in the channels and hidden from the eyes of strangers by screens and decor, so you should not worry about beauty and aesthetic appearance. Another thing is important - incorrect temperature control and overheating of the pipe or fitting material, even under a little effort, will lead to marriage. In soldering, the first and main issue is the quality of the connection of parts.

If, when working with a homemade soldering iron, you can slightly fall short of world standards appearance- it does not matter, for amateur cases it is allowed.

To assemble a homemade propylene pipe soldering iron, you will need:

- The heating element is the soleplate of an ordinary electric iron, preferably in the form of a closed aluminum block with a thermostat and an electric cord with a plug;

- nozzles for a soldering iron for polypropylene pipes and fittings of the required size for your pipes;

- nickel-plated M8 bolt-nut for fixing nozzles on the heater;

- digital multimeter with external thermometer based thermocouple;

- a clamp or other fastener that allows you to securely fix the soldering iron on an auxiliary surface.

In addition to temperature, the speed or power of heating the surface of the parts to be joined is important. If you heat a polypropylene fitting or pipe for a long enough time, the parts will lose their shape and geometric dimensions under the influence of temperature.

Therefore, for the rapid melting of a surface with a diameter of 15–30 mm, a power of 700–900 W is required, which approximately corresponds to maximum power iron heater.

We collect homemade for propylene couplings:

- At a distance of 30-40 m from the bow of the aluminum sole we drill through hole with a diameter of 8 mm and with the help of a screw and a nut we connect the nozzles for the pipe and fitting to the base of the heater;

- We install the handle of the iron on the sole-heater so that it does not restrict access to the fixed nozzles;

- We connect the wiring to the contacts of the iron heater;

- We turn on the network and use a multimeter, a digital thermometer and a regulator on the iron to set the temperature to 265 ° C.

We use the clamp to fix a home-made soldering iron of polypropylene pipes, which will allow you to solder the parts yourself, without an assistant, the handle can also be made for yourself for the greatest convenience and minimal risk of getting burned.

Which soldering iron for polypropylene pipes is better

It has always been considered that the best tool is a professional option designed for long-term use and has high parameters for soldering propylene pipes. Professional soldering iron for polyethylene pipes suggests:

- Application for nozzles of materials resistant to prolonged heating, with high thermal conductivity, not sticking to the heated surface of the polypropylene part; as a rule, brass or copper nozzles coated with teflon or carbon are used;

- Easy and convenient change of nozzles on the heater flange, the kit includes a set for the main pipe sizes - from 16 to 160mm;

- The metallized surface of the nozzles gives a high heating rate of the polypropylene parts;

- The presence of a power supply stabilizer for the heater and auto-regulation of temperature allows you to keep the soldering iron hot for as long as you like without the risk of failure of the heating element.

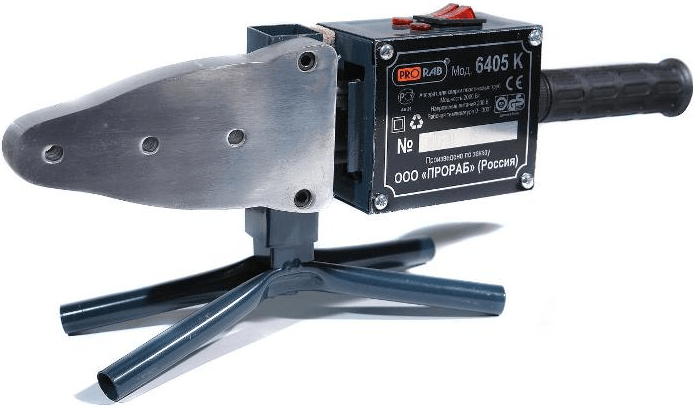

Mandatory attributes of professional models of soldering irons are an easily removable stand and a case for storing and carrying the device with accessories.

For your information ! For original models of soldering irons, unlike fakes, markings and information about the model are printed in a typographical way on the case or on a metal substrate plate, tightly soldered into plastic. On fakes, the marking is pasted in the form of a metallized label and is easily separated from the body of the soldering iron.

For example, a well-known version of a soldering iron for polypropylene pipes dytron or ditron - as you like. He is highly rated for reliability and ease of use, unpretentiousness and solid construction. When soldering propylene parts, the time goes by in seconds, you have to quickly put, drop or even throw the stick on the stand, and this practically does not affect its performance. There are three models in the DYTRON line:

- With a power of 850 W, the most popular in apartment renovation, it is used for a polypropylene pipe with a diameter of up to 36 mm;

- Power 1200 W - for polypropylene pipes with a diameter of up to 160 mm;

- With a heater in the form of a rod, with a power of 650 watts.

The soldering iron comes with a wrench for changing nozzles, which can be from 3 to 12 in the kit, scissors for cutting polypropylene pipes, building level, gloves and stand. With all the advantages, it is worth noting one negative point - the obviously overpriced soldering iron.

Important ! Such devices are designed for many hours of operation, but in any case, they require careful maintenance. non-stick coating on nozzles. Teflon is very sensitive to scratches and chips, so you should not use hard or metal objects for cleaning, except for rags.

But even specialists involved in soldering water pipes do not always strive to buy a soldering iron for polypropylene pipes in an expensive professional design. Many of the budget models assembled from Chinese or Turkish components work just as well as branded models.

Let's take for example a typical workhorse of a repairman - a soldering iron for Soyuz polypropylene pipes:

- High heater power - up to 2 kW;

- The kit includes six typical nozzles with a diameter of 20 to 63 mm;

- In addition, the soldering iron is equipped with a hexagon - a key for changing the working tool, a stand for the device and a case.

The length of the power cord is only 130 cm, which is clearly not enough for work. But this size is typical for budget models, while professional soldering irons have a full 2.5-3.5m. "Soyuz" is equipped with a two-mode push-button heating control system and two color indicators - green and red, the latter lights up when the automatic heating is turned on.

The soldering iron is equipped with everything necessary for the successful soldering of polypropylene pipes, so it is difficult to say whether it is worth overpaying for additional accessories, as in the case of expensive soldering iron models.

Often, when operating household plumbing systems made of polypropylene, it becomes necessary to repair or build them up, which is impossible without special equipment for soldering. As a tool suitable for these purposes, purchased devices of a special design are usually used, the high cost of which forces users to think about making them with their own hands.

This approach is good not only because it allows you to save significant funds and not waste time learning how to work with unfamiliar equipment. Thanks to self-manufacturing it is possible to study all the subtleties of handling such devices, which, ultimately, affects the quality of soldering polypropylene and other plastic pipes.

In the event that a decision is made to make a soldering iron for pipes with your own hands, this can be done using the old spare parts left in the household. One of the most common options for its manufacture from improvised means involves the use of an electric iron that has already served its time for these purposes.

To implement this project, you will need the following components and spare parts:

- an old iron rated for at least 800 watts;

- duralumin plate of a suitable size;

- steel slats from an old children's designer;

- wires, a toggle switch, an unnecessary handle from a disassembled drill or grinder, so that it is convenient to hold the soldering iron.

A soldering iron for iron pipes works on the same principle as a factory specialized product. The spiral (heater) heats up, transfers heat to the sole, and the nozzle inserted into it. This allows you to melt polypropylene pipes and solder them. The temperature on a homemade soldering iron is set to the maximum (should be 260-265 ℃). Having prepared all these parts and materials, it will be possible to begin the assembly.

First, the casing is removed from the iron, which allows access to its insides. Then the working part of the sole is cut off by means of a grinder, and in its place with an existing bolt, a duralumin plate cut to the shape of the base is attached. Next, from the spare parts of the designer, you need to assemble the box and securely fix it on the sole.

A toggle switch and a handle from a grinder are fixed on the elements of the box, after which one end of the network wire is connected to the switch. The second conductor, together with the outlet from the toggle switch, is connected to the heating coil through asbestos tubes.

Nozzles for fixing on polypropylene pipes will have to be purchased separately. If desired, a socket with a light bulb can be connected in parallel with the power circuit, the current through which must be limited by means of a quenching resistor. In order to make this simple design do-it-yourself will take a minimum of time.

With heating controller

To control the heating temperature of a homemade soldering iron for polypropylene pipes, a thermocouple is installed. To assemble a device equipped with a working sole heating regulator, you will need additional parts and spare parts, namely:

To control the heating temperature of a homemade soldering iron for polypropylene pipes, a thermocouple is installed. To assemble a device equipped with a working sole heating regulator, you will need additional parts and spare parts, namely:

- thermostat, thermocouple and two tips;

- pointer indicator with a special scale (with "zero" and two sectors);

- conductors in insulation with a length of at least one meter each;

- asbestos wool.

Even before starting work, you should contact the turner and ask him to make two tips of a special shape (under the fitting and under the heater outlet). The dimensions of these tips are selected based on the diameter of the tube prepared for assembly.

The do-it-yourself assembly order of a soldering iron for polypropylene with a thermostat looks like this:

- First, the casing is removed from the iron, after which the temperature controller is removed from its soleplate, as well as all unnecessary details and wiring. After such disassembly, a clean ironing plate should remain.

- Then, using a drill, holes are drilled in the tips with a diameter of about 6 millimeters, after which they are bolted to the body cleaned of foreign parts (from the “nose” side). On the opposite side of the sole, holes are drilled in it with a diameter suitable for mounting the thermocouple housing.

- Wires about one meter long are soldered to the thermocouple. Following this, by means of the same conductors, the supply to the heating coil is carried out. All these wires are brought out through the hole in the iron handle. She herself is attached directly to the casing.

- At the final stage of work, the space between the casing and the slab is filled with asbestos material (wool), which acts as a heat insulator. Upon completion of this operation, the casing is returned to its place, resulting in a casing with two pairs of conductors brought out.

These wires are connected to the power plug and the thermostat according to a scheme that allows you to set the set value for the melting temperature of polypropylene (255-265 °).

Thermostat circuit and printed circuit board

Industrial designs with paired nozzles

For the manufacture of thermal nozzles of industrial soldering irons, special materials are used that conduct heat well (copper, aluminum alloys and the like).

For the manufacture of thermal nozzles of industrial soldering irons, special materials are used that conduct heat well (copper, aluminum alloys and the like).

Outside, they are covered with a special layer that prevents polypropylene from sticking (most often Teflon is used for this purpose).

Known samples of nozzles for soldering propylene pipes differ both in their shape and in the method of attachment to the heater, which can be various designs. In this case, preference is usually given to products that allow you to install paired nozzles (or several pairs of them at once).

The possibilities of such a device are significantly expanded, since it becomes universal in terms of its technical indicators.

The working dimensions of the soldering iron nozzles (their diameters) must correspond to the same indicator for polypropylene pipes and have values from 16 to 110 millimeters.

Special nozzles with sizes from 20 to 32 millimeters should be included in the kit of any soldering iron that belongs to the category of semi-professional devices. Specialized models of soldering tools can be equipped with a large number paired nozzles, the range of sizes of which is extended to 63 millimeters.

Plastic plumbing has come to our life for a long time and for a long time. An invariable attribute of the repair of the Soviet housing stock, along with metal-plastic windows, was a water supply system made of polypropylene pipes.

The advantages of polypropylene water pipes over steel pipes are obvious:

- Cheapness and a wide choice of materials;

- Ease of marking and assembling the most intricate and complex pipe layout options;

- Environmental friendliness, material resistance to corrosion and salt deposits on the walls of polypropylene communications.

Those who have encountered the tedious and time-consuming procedure for installing a water pipe from metal pipes can appreciate the simple technique of joining plastic using a special soldering iron for polypropylene pipes.

If the time has come to repair the apartment, the problem of replacing the water supply with plastic communications, depending on the availability of desire, money and free time, is solved:

- Hiring a craftsman and a friend who has experience with a device for soldering propylene pipes, who can help assemble pieces of plastic pipes marked and cut into a single whole with a soldering iron;

- Transferring the issue of turnkey repair to a team of repairmen without any desire to deal with the intricacies of assembling and soldering plastic assemblies;

- Doing all the work with your own hands.

The simplicity of plastic soldering assembly is so captivating that it is difficult to resist the temptation and solve the plumbing problem only by choosing and buying a soldering iron for polypropylene pipes.

The amount of money spent on the purchase of a tool will be less than the cost of the services of a master, but on the condition that you really understand how to choose a soldering iron for polypropylene pipes. In fact, a soldering iron for propylene parts and connecting fittings is a heating element with a thermomechanical or electrical heating control system and indication. Two nozzles are mounted on the heater, which allow simultaneously heating the outer surface of the pipe and the inner surface of the fitting with a soldering iron. Heating lasts an average of about 5 s, the parts are connected with a slight pressure by hand to set and form a strong connection within 2-3 s. In case of overheating or a crooked connection of parts, a part of the molten plastic may get inside the pipe, as a result, the flow area decreases.

Important! By doing most of the soldering and assembly work yourself, you are able to personally control the quality of the soldering of polypropylene pipe joints.

For innovators and DIY enthusiasts, you can assemble a soldering iron for polypropylene pipes with your own hands. The strength and durability of soldering depends on the perfection of the soldering iron and how high-quality polypropylene pipes are.

What is good soldering iron assembled by hand

The principle of operation of the soldering iron is simple and uses the principle of adhesion of polypropylene parts heated to the softening temperature of the soldered surfaces. There is not always a need to re-wire or re-solder half of the plumbing in the house. Sometimes you need to work with a soldering iron for two or three connections. In this case, a home-made, do-it-yourself mini-soldering iron for polypropylene pipes from an improvised heater can help out.

For a person with experience with electrical wiring and plumbing skills, making a small amateur version of a soldering iron for polypropylene pipes is a matter of two hours.

As a rule, water pipes are laid in channels and hidden from prying eyes by screens and decor, so you should not worry about beauty and aesthetic appearance. Another thing is important - incorrect temperature adjustment and overheating of the pipe or fitting material, even under a little effort, will lead to marriage. In soldering, the first and main issue is the quality of the connection of parts.

If, when working with a homemade soldering iron, you can slightly fall short of the world standards of appearance - it does not matter, for amateur cases this is allowed.

To assemble a homemade propylene pipe soldering iron, you will need:

- The heating element is the soleplate of an ordinary electric iron, preferably in the form of a closed aluminum block with a thermostat and an electric cord with a plug;

- nozzles for a soldering iron for polypropylene pipes and fittings of the required size for your pipes;

- nickel-plated M8 bolt-nut for fixing nozzles on the heater;

- digital multimeter with external thermometer based thermocouple;

- a clamp or other fastener that allows you to securely fix the soldering iron on an auxiliary surface.

In addition to temperature, the speed or power of heating the surface of the parts to be joined is important. If you heat a polypropylene fitting or pipe for a long enough time, the parts will lose their shape and geometric dimensions under the influence of temperature.

Therefore, for the rapid melting of a surface with a diameter of 15-30 mm, a power of 700-900 W is required, which approximately corresponds to the maximum power of the iron heater.

We collect homemade for propylene couplings:

- At a distance of 30-40 m from the bow of the aluminum sole, we drill a through hole with a diameter of 8 mm and, using a screw and a nut, connect the nozzles for the pipe and fitting to the base of the heater;

- We install the handle of the iron on the sole-heater so that it does not restrict access to the fixed nozzles;

- We connect the wiring to the contacts of the iron heater;

- We turn on the network and use a multimeter, a digital thermometer and a regulator on the iron to set the temperature to 265 ° C.

We use the clamp to fix a home-made soldering iron of polypropylene pipes, which will allow you to solder the parts yourself, without an assistant, the handle can also be made for yourself for the greatest convenience and minimal risk of getting burned.

Which soldering iron for polypropylene pipes is better

It has always been considered that the best tool is the professional version, designed for long-term use and with high parameters for soldering propylene pipes. A professional soldering iron for polyethylene pipes involves:

- Application for nozzles of materials resistant to prolonged heating, with high thermal conductivity, not sticking to the heated surface of the polypropylene part; as a rule, brass or copper nozzles coated with teflon or carbon are used;

- Easy and convenient change of nozzles on the heater flange, the kit includes a set for the main pipe sizes - from 16 to 160mm;

- The metallized surface of the nozzles gives a high heating rate of the polypropylene parts;

- The presence of a power supply stabilizer for the heater and auto-regulation of temperature allows you to keep the soldering iron hot for as long as you like without the risk of failure of the heating element.

Mandatory attributes of professional models of soldering irons are an easily removable stand and a case for storing and carrying the device with accessories.

For example, a well-known version of a soldering iron for polypropylene pipes dytron or ditron - as you like. He is praised for reliability and ease of use, unpretentiousness and solid construction. When soldering propylene parts, the time goes by in seconds, you have to quickly put, drop or even throw the stick on the stand, and this practically does not affect its performance. There are three models in the DYTRON line:

- With a power of 850 W, the most popular in apartment renovation, it is used for a polypropylene pipe with a diameter of up to 36 mm;

- Power 1200 W - for polypropylene pipes with a diameter of up to 160 mm;

- With a heater in the form of a rod, with a power of 650 watts.

The soldering iron comes with a wrench for changing nozzles, which can be from 3 to 12 in the kit, scissors for cutting polypropylene pipes, a building level, gloves and a stand. With all the advantages, it is worth noting one negative point - the obviously overpriced soldering iron.

Important! Such devices are designed for many hours of operation, but in any case, they require careful maintenance of the non-stick coating on the nozzles. Teflon is very sensitive to scratches and chips, so you should not use hard or metal objects for cleaning, except for rags.

But even specialists involved in soldering water pipes do not always strive to buy a soldering iron for polypropylene pipes in an expensive professional design. Many of the budget models assembled from Chinese or Turkish components work just as well as branded models.

Let's take for example a typical workhorse of a repairman - a soldering iron for Soyuz polypropylene pipes:

- High heater power - up to 2 kW;

- The kit includes six typical nozzles with a diameter of 20 to 63 mm;

- In addition, the soldering iron is equipped with a hexagon - a key for changing the working tool, a stand for the device and a case.

The length of the power cord is only 130 cm, which is clearly not enough for work. But this size is typical for budget models, while professional soldering irons have a full 2.5-3.5m. "Soyuz" is equipped with a two-mode push-button heating control system and two color indicators - green and red, the latter lights up when the automatic heating is turned on.

The soldering iron is equipped with everything necessary for the successful soldering of polypropylene pipes, so it is difficult to say whether it is worth overpaying for additional accessories, as in the case of expensive soldering iron models.

bouw.ru

Soldering iron for polypropylene pipes: instructions on how to use an electric soldering iron, what caliber to use nozzles for soldering, how to choose a soldering iron among manufacturers

Soldering iron for polypropylene pipes: instructions for use

Factory or even homemade soldering iron for polypropylene pipes - an almost indispensable thing if you decide to independently replace the pipelines in the apartment.

The use of soldering equipment allows you to quickly and reliably connect polypropylene pipes, ensuring the tightness of such a connection.

The principle of operation of the soldering iron for pipes

The device, which we most often refer to as a soldering iron for polypropylene pipes, from a technical point of view, is correctly called the “Apparatus for resistance welding pipes with a heated tool.

Soldering iron for polypropylene pipes

Principle of operation this machine simple enough:

- The soldering iron is connected to the mains

- Nozzles for a soldering iron of polypropylene pipes are installed in special nests, the diameter of which corresponds to the diameter of the connected pipes

- We put on the pipe sections to be welded on the nozzles, which gradually heat up

- We remove the pipes heated up to the beginning of melting of polypropylene from the nozzles and join

Thus, a soldering iron for soldering polypropylene pipes allows you to quickly create a reliable and tight (though one-piece, i.e. permanent) pipe connection.

At the same time, the cost of soldering irons and ease of operation allows you to use soldering irons for polypropylene pipes on your own, without involving craftsmen "from outside".

As you can see, a soldering iron for polypropylene is very useful tool. And so that you do not make a mistake when choosing a soldering iron, below we provide a few recommendations for selecting models.

Key parameters, determining the choice of soldering iron, will be:

- Soldering iron power

- The presence of interchangeable nozzles (as well as their range)

- Manufacturer country

Soldering iron power for polypropylene pipes

The first, and perhaps key characteristic soldering iron is its power. The power of the soldering iron for polypropylene pipes determines the maximum diameter of the pipe, the welding of which the soldering iron is guaranteed to cope with.

At the same time, the more power, the larger pipes you can weld with a soldering iron. For example, a cobra soldering iron for polypropylene pipes with a power of 1.5 kW allows you to weld polypropylene pipes. the diameter of which is in the range from 20 to 50 mm, and a more powerful power machine (1700 W) makes it possible to connect pipes up to 63 mm in diameter.

This dependence is not linear; not always the high power of the soldering iron means that it is suitable for working with pipes large diameter.

For example, the ditron soldering iron (model TraceWeld PROFI blue), which has a “modest” power of 850 W, is capable of high-quality welding of pipes with a diameter of up to 63 mm, which other soldering iron models are not capable of, the power of which is much higher (for example, fora or already mentioned here Cobra).

Another aspect that is affected by the power of the soldering iron is the speed of operation - the more powerful the device, the faster you can connect the pipes (less time it takes to warm up).

And here you need to choose: if you need to make only a few connections, then the low-power caliber SVA-750T (750 W) is quite suitable. And if you need to solder a lot, then it is better to take a model with more power, for example valtec 1500 W.

Quite often they say that when choosing an electric soldering iron for polypropylene pipes, its required power can be calculated by multiplying the maximum diameter of the pipe being welded by 10. This rule is partly true, but only partly - it must be used with caution.

The reasons why it is necessary to choose a soldering iron for polypropylene pipes by analyzing all the manufacturer's recommendations, we indicated above.

Nozzles for soldering iron

When choosing a soldering iron for polypropylene pipes in accordance with the given needs, it is very important to take into account the presence of various nozzles in the soldering iron kit. If you purchase a soldering iron equipped with various nozzles, it will be much easier for you to weld polypropylene pipes of different diameters.

Another advantage (although it is more relevant for professionals who weld a large number of pipes regularly) is the possibility of parallel installation of several nozzles. Such an opportunity is provided, for example, by a candan soldering iron for polypropylene pipes.

Teflon coated tips

When purchasing a soldering iron, pay attention also to the coating of the nozzles. The most functional are soldering tips with Teflon coating, as well as tips coated with metallized Teflon.

Such nozzles not only warm up more evenly, but also last much longer. Teflon-coated nozzles are equipped with the already mentioned soldering irons candan, dytron and others.

Equipment

In addition to the soldering iron itself and nozzles, the soldering machine may also include additional tools and accessories, ranging from scissors for cutting polypropylene pipes to special gloves that will save your hands from burns when welding polypropylene pipes with your own hands: advice from masters.

Most manufacturers pack soldering irons in special carrying cases - plastic or metal.

Manufacturer country

An important role is also played by the fact where the soldering iron of polypropylene pipes you have chosen is produced.

And although today the “pedigree” of the soldering iron is not so important (globalization, after all), some patterns in geography are still present:

- Czech soldering irons for polypropylene pipes rightfully occupy a leading position in the informal rating of these devices. Despite not the lowest cost, Czech soldering irons (such as the Daitron repeatedly mentioned today) are in steady demand. So if the quality of the instrument comes first for you, the Czech Republic has no alternatives.

- Turkish soldering irons are somewhat of a compromise. Turkey produces both excellent models that can "plug another Czech into the belt" - and models of frankly poor quality.

That is why, having decided to purchase a Turkish soldering iron, you need to carefully approach the choice specific model by reading reviews online.

Soldering iron ENERGOMASH (STURM)

A separate niche in this market is occupied by Chinese soldering irons. On the one hand, China has been and remains China, with its permanent features: democratic and completely affordable price and unpredictable quality. On the other hand, in fact, many European and domestic (according to the sticker) soldering irons are also produced at the production facilities of the Middle Kingdom - while quality control at such enterprises ensures the output of quite competitive products.

Such devices include the Energomash soldering iron for polypropylene pipes (it is also produced under a different brand - sturm).

- Well, completely different are home-made soldering irons for polypropylene, made by "craftsmen" using a variety of technical solutions (most often - spirals from irons). Such devices work unpredictably, so we will not take the liberty of recommending them for use. Yes, and from the point of view of electrical safety, such homemade products are most often not flawless (this is, to put it mildly!)

In fact, the modern electrical equipment market demonstrates a fairly direct relationship between the price of a soldering iron and quality. Thus, if you buy an inexpensive Chinese device, then, most likely, it will serve you for a short time.

But if you plan to work with pipes for a long time, then it is better to immediately purchase a more expensive soldering iron - polypropylene pipes and it will be easier to weld, and the weld will be more reliable. Moreover, the range of soldering irons for polypropylene pipes, available in building supermarkets and online stores, allows you to choose a model for almost any requirement and “for any budget”.

Guided by the above considerations, you can choose the best soldering iron for polypropylene pipes for you: the instructions for such a device, included in the kit or available on the manufacturer's website, will allow you to choose optimal mode work. And literally after a couple of attempts, you will be able to connect the pipes in your apartment with high quality when replacing them!

More information

Polypropylene pipes, due to their low cost and ease of connection, are used by many owners when installing plumbing in an apartment or house. There are many tools for soldering pipes, but not everyone can afford them, so I made a soldering iron from an old electric iron.

On the "sole" from the iron (heater) (photo 1, item 1) in advance drilled hole using a bolt on both sides, I fixed the heating element for the outer (7) and inner (see photo 2) pipe diameters. The heat-insulating casing (photo 1, p. 2) and the temperature controller module (3), fixed on the textolite plate (4), were connected to the heating element and installed on the stand (5). Between the casing and the plate placed fluoroplastic insulators (6)

The aluminum stand securely holds the structure, and the protruding part of the textolite plate is freely inserted into its groove (8) and easily removed, which makes it convenient to store the device. wooden handle attached with screws to the textolite. The temperature controller module was assembled according to the scheme ...

When installing the water supply, I turn on the soldering iron, set the desired temperature. I insert pipes d 25 mm from both sides into the heating element for no more than 5 seconds, take them out and solder them together, connecting the heated ends.

Scheme of a homemade soldering iron for plastic pipes

1. Variable 500 kOhm (R 1)

2. Resistor 4.7 kOhm 0.5 w(R2)

3. Resistor 1mΩ, 0.25w(R3)

4. Dinistor DB-3(VS 1)

5. Triac TC 25-4 (VS 2)

6. Thermal electric heater 1000w(T3H)

7. Capacitor 0.1uF, 400v(C 1)

8. Neon lamp HL 1 (network indicator)

The temperature controller is mounted in aluminum housing 130x60x90 mm in size on a foil fiberglass board. The control knob is brought out and has divisions. When the device is turned on, the red lamp lights up.

Do-it-yourself soldering iron for plastic pipes - photo

Classic Base Decals plastic bricks props compatible with legoingly city…

Classic Base Decals plastic bricks props compatible with legoingly city…

82.16 rub.

Free shipping★★ ★★ ★★ ★★ ★★ (4.90) | Orders (1126)

2019 10pcs/lot children's castle Child protection lockable doors for…

2019 10pcs/lot children's castle Child protection lockable doors for…

Pipes and fittings made of polypropylene today can be said to be in trend. They are used for inside house and apartment plumbing and heating wiring and networks. The popularity of this material is due primarily to the convenience of working with it. Unlike metal pipes, they do not need to be bent with a pipe bender, threaded and welded. All the laboriousness of this profession has remained in the past with the advent of such material as polypropylene.

The main tool for working with polypropylene products is an electric soldering iron or iron. In the factory kit, it is equipped with nozzles-sleeves for soldering pipes and fittings of standard diameters. They can also be purchased separately. But there are times when, for some reason, a factory soldering iron is not available and there is no way to buy it, and of all the parts, only welding nozzles are available. This is where a homemade plumbing soldering iron comes in handy.

This homemade product is from the category of "blew, spat and did the job." You can literally assemble it on your knees from an old iron and a wooden block. With such a homemade heater, you will definitely save the situation and cope with the soldering of polypropylene pipes. And how to do it, we will now show.

What you need to assemble a soldering iron

- An old iron with a working heating sole;

- Wooden block, approximate section 40x50 mm, length 40-50 cm;

- Four self-tapping press washers, 3x14-16 mm;

- Nozzles-sleeves for a sanitary soldering iron with a clamping bolt;

- Power cable with plug;

- Insulating tape, self-tapping screws 45 mm.

We assemble a homemade soldering iron for polypropylene pipes

First of all, we disassemble the household iron, disconnecting the sole from the thermostats. We won't need the rest of the iron anymore.

Next, we prepare wooden block. If necessary, it can be sawn, planed or simply cleaned on emery wheel, as the author of the homemade product did (photo).

To fix the bar, we drill several holes on the sole of the iron, in a zone free from the heating element. The diameter of the drill should be less than the width of the screw head.

We insert the bar fitted according to the section into the groove of the sole, and fasten it to several self-tapping screws using a screwdriver and a cross nozzle.

There are bolts at the end of the contact group of the heater. Under them, we drill grooved holes on both sides of the bar, and unfold the contacts with pliers to connect them.

We press the contact plates with several self-tapping screws - press washers.

Not far from the end of the sole, we drill a hole for the clamping bolt for the sleeves. Now you can attach several paired welding nozzles. We sit them on the clamping bolt, and tighten with a hex wrench.

All that remains is to connect the power cable to the contact group, and wrap the contact area on the handle with electrical tape.

The soldering iron is ready to go. Such a device can be used for soldering polypropylene pipes and fittings, making plumbing or heating wiring.