Content:

Covering walls, ceilings and other elements of the internal living space of a country house or apartment with finishing materials made of natural wood is, firstly, an opportunity to give the space of the house a special decorative effect and, secondly, to protect them from mechanical influences and excess humidity.

When finishing the interior walls of a house, between the sheathing and the finishing surface, as a rule, a multilayer structure is laid, which has protective, sound and heat insulating qualities.

The invaluable advantages of natural wood as a cladding material for the exterior and interior decoration of a house allow us to consider this material almost irreplaceable in many respects. In this article we will consider and compare interior finishing options, detailing their advantages and disadvantages.

Despite external associations with the lining we described above, it is practically a new European “invention”. This finishing material differs from lining in a number of tangible advantages. The first is compliance with strict European (primarily German) quality standards, which in itself is a convincing argument in its favor.

The quality of eurolining and the level of environmental friendliness of technological processes is controlled at almost all stages of its production, and even earlier - starting with the choice of wood. Wood is mainly used as a raw material for the production of eurolining. coniferous species trees, often purposefully grown. But, even with such strict control, eurolining is divided into classes - first, second and third.

Eurolining is distinguished from standard lining and exceptionally precise geometric dimensions of surfaces, which allows assembly with minimal tolerances. As a result, both the finished surface and its individual fragments are very decorative. In addition to the noted advantage, the eurolining is additionally equipped with a moisture removal and ventilation system in the form of a groove specially designed for this purpose. This solution makes it possible to provide increased durability both the lining itself and the main wall of the house. Distortion of the sheathing due to swelling of wood fibers in rooms with high humidity is also eliminated.

The ideally smooth and pleasant-to-touch surface of the eurolining is coated with special compounds in production, which makes it possible to avoid additional treatment with paints and varnishes, as is the case with conventional lining. At the same time, the texture of the wood, unique to each species, remains the focus of the “viewer’s” attention.

Today it is becoming a source of special pride for owners of luxury houses, cottages, and restaurants. Thanks to its unique decorative properties and composition, high-quality eurolining creates a healthy microclimate, comfort and special coziness in the house.

|

|

|

When the walls and ceiling are ready, decorated and breathe freshness, cleanliness, conducive to a pleasant time with a cup of aromatic herbal tea, as it turns out, it’s too early to relax - you should think about flooring! Of course, in the best traditions of lovers of a healthy lifestyle, the flooring should also be natural, i.e., wooden.

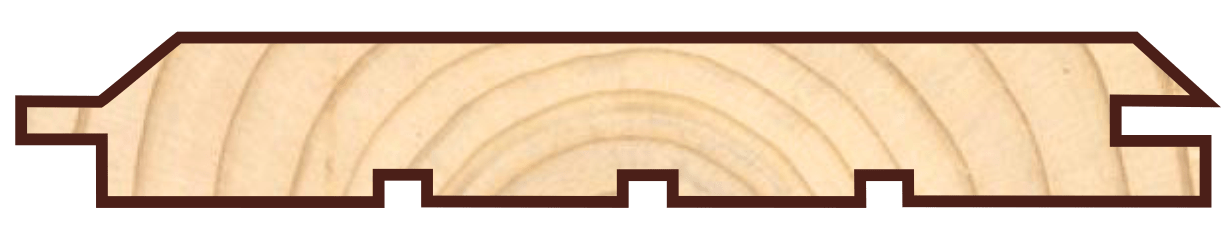

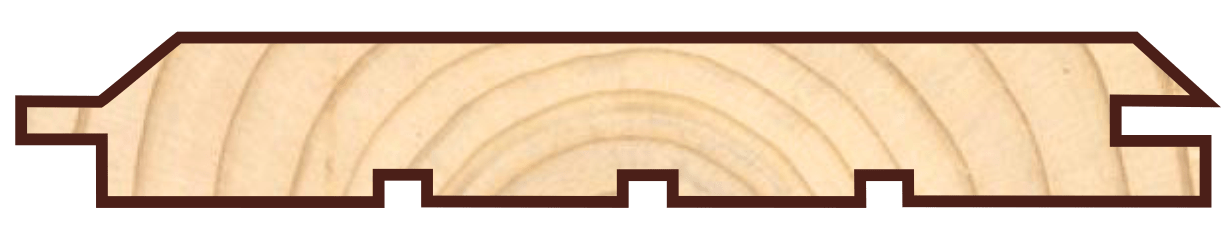

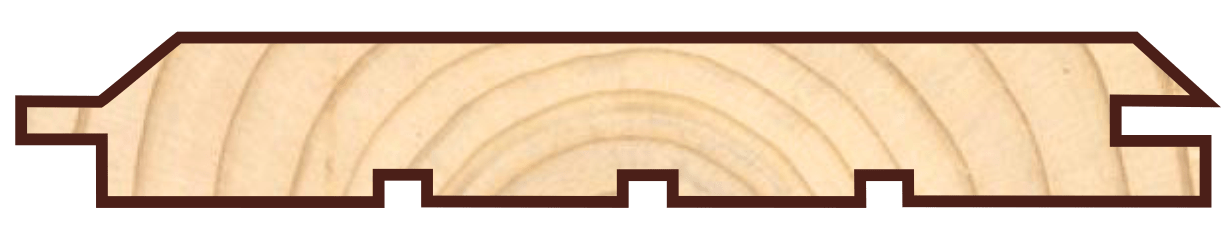

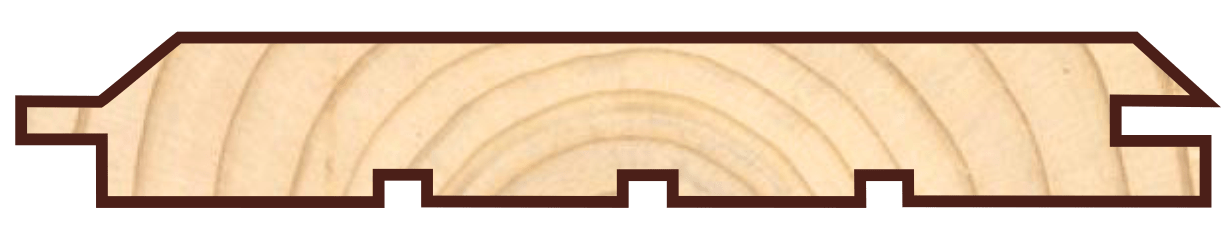

This is a molded product, tongue-and-groove on both sides, manufactured on modern high-precision woodworking equipment from selected boards of both tangential and radial cuts. The humidity of the finished quality product should not exceed 10%.

Belonging to the category of elite and most expensive natural materials For interior decoration of a house, solid floorboards have many advantages, the main ones of which are: a healthy microclimate in the house, warmth, comfort when walking, high decorativeness and durability. The last point deserves special attention, and the best proof of this is European castles that have stood for more than 500 years and still delight tourists with “authentic” solid wood floors.

Considering that modern technologies Drying wood and using valuable wood species in the production of solid floorboards make it possible today to obtain a product with unique performance characteristics. Such a massive board “breathes,” that is, it sensitively reacts to changes in humidity in the room, actively absorbing its excess and thereby “optimizing” the microclimate in the room. To the long list of advantages of solid floorboards we should add low thermal conductivity and high sound insulation qualities. The massive board is connected using the tongue-and-groove principle, which allows for high-quality installation quickly and accurately.

Modern finishing coating, solid floor boards, are manufactured in accordance with the requirements of Russian and European standards. It is possible to saw a “chamfer” along the entire length of the board, which gives the finished coating originality and special expressiveness.

One of the main advantages of solid floorboards is the possibility of repeated renovation. Since the thickness of the working layer is in the range of 12 – 45 mm, the board can be sanded, accordingly, at least 15 times. Very popular in production wooden board The floors are Siberian larch and Angara pine. In order for a solid board to serve you faithfully for many years, you should take into account the requirements for protection from impacts, moisture, heat and sound insulation. Will contribute greatly to this right choice substrates. An excellent option is the Kraiburg underlay, which can significantly improve the wear resistance of laid solid boards, smooth out micro-irregularities in the base, and therefore significantly improve and extend the life of the coating.

Solid plank flooring looks best in large rooms, especially where there is sufficient natural light. The service life declared by the manufacturers is at least 100 years - enough for our lifetime!

Wooden block - house in interior decoration

The amazing decorative properties, reasonable price and environmental neutrality of the block house determine its popularity as practical and easy to maintain. finishing material. for both exterior and interior decoration. Various types of wood can be used as material for the production of block houses, but the most common are, of course, pine and Siberian larch. The high degree of drying of block-house wood guarantees its durability and resistance to cracking, warping and other deformations. A block house made of cedar, birch or linden looks very decorative.

Installable in your home block house free from the disadvantages characteristic of a log house made of rounded logs, in particular, spoiling the decorative appearance longitudinal cracks. Impregnation with antiseptics and fire retardants allows for improved performance characteristics.

Walls made of brick, foam concrete, concrete and other undecorative surfaces after finishing with a block house look simply amazing. The low cost of a block house allows the use of this unique finishing material both for finishing private houses and cottages, and for interior decoration of cafes and hotels decorated in country style. The block-house panels used for interior decoration are smaller in thickness and width (20mm x 80...90mm, respectively) than the panels used for exterior decoration. In the corners, individual panels are joined with special corners, which allows you to create the feeling of a solid facade.

All lining goes through the same production cycle, and only at the final stage of sorting is it divided into grades based on external characteristics.

- grade “A” allows the presence of knots light color;

- grade “B” allows the presence of “dead” dark-colored knots.

In this case, fallen knots and visible defects are not allowed.

The high concentration of resin and the hardness of larch wood make it very difficult to process, but in return they provide ready product unique operational and environmental characteristics. The atmosphere of the house, the walls of which are covered with larch finishing material, is saturated with phytoncides - substances that have a beneficial effect on the lungs, cardiovascular and nervous system owners and guests of the house. A larch block house is strong and durable, the quality of the best “Extra” class block house meets European standards.

Decorating a house with imitation timber

- molded product, a type of lining, actively used today for interior and exterior finishing houses, saunas, baths, apartments. Imitation of timber is not only an effective finishing material that allows you to create a feeling of comfort and coziness in a room, but it is precisely the material that allows you to completely transform the space of your home with minimal means. Such drastic changes will not require a global reconstruction of the building, moving walls and partitions.

Choosing wood for interior decoration

Tree different breeds- a perennial favorite exclusive design interior, and is perfect for use in creating both modern and traditional styles. Among hardwood oak, ash, walnut and maple are valued; among conifers, pine, spruce, cedar and mahogany are excellent choices. The first thing you will need, regardless of what finishing material you use, is to decide in favor of hardwood or softwood. The question is not as simple as it seems at first glance, and for a qualified answer to it, you would still be better off contacting your architect or contractor.

- Availability of a particular material;

- How ready is the type of wood you are interested in for the processing you need?

- How labor-intensive will it be to care for such finishing coating;

- To what extent does the selected option meet the wear resistance requirements imposed by the operating conditions?

Estimated prices for interior finishing materials

Some types of work:

- Installation of lining - 300 rub. / sq.m.

- Installation of a block house - 400 rubles. / sq.m.

- Installation of imitation timber - 400 rubles. / sq.m.

Estimated cost of turnkey finishing with wood

Room size 15 sq. m. With a ceiling height of 2.5 m - 1630 rub./sq.m. The cost of finishing includes:

- covering the ceiling and walls with clapboard;

- installation of floor and ceiling plinth;

- clapboard covering of window and door slopes;

- installation of joists and floorboards.

Interior decoration of a house with materials made from natural wood is an excellent investment in healthy image life, the opportunity to surround yourself with elements of style created and honed by the most perfect designer of all existing - nature itself.

Interior and exterior design made of wood always looks beautiful, environmentally friendly and safe. Wood allows you to add uniqueness to the premises, add zest, fill it with a pleasant aroma, insulate and protect the house from excessive humidity. In this article we will talk about the types of finishing materials made of wood, the advantages and disadvantages, and also help you choose the right material for the interior and external cladding Houses.

Types of materials and scope

Wood products are widely used for both interior and exterior decoration of the house. Wood is used for cladding:

- walls;

- facades;

- flooring;

- stairs;

- internal and load-bearing partitions;

- window and door openings;

- individual elements decor.

Finishing materials made from natural wood can create an excellent microclimate in the room, as well as perform the function of sound and noise insulation, hide defects and emphasize the individuality of the interior. The construction market offers a large selection of wood-based materials. The following materials are used for interior and exterior decoration:

- block house;

- lining;

- decking;

- decorative wallpaper;

- wood panels;

- parquet and floor boards;

- laminated veneer lumber;

- Gusvarblok;

For internal or exterior finishing The types of deciduous trees most often used at home are ash, oak, walnut or maple. But among coniferous species, as a rule, pine, cedar or mahogany are chosen. To make the choice easier, you can use product evaluation criteria:

- availability of material;

- difficulty in caring for the product;

- what degree of material processing will be required during its installation;

- compliance of the material with wear resistance requirements and operating conditions.

Anyway, before you buy facing material, you should learn about each product in detail.

Characteristics of facing materials

Wood-based materials provide ideal finishing various designs made of concrete, metal or brick. Coniferous trees are most often used for interior decoration of ceilings and walls; for flooring and stairs they are used hard wood, but for exterior decoration they use wood with high density and resistance to the external environment. Let's consider the characteristics of wooden products.

Block house

Block house is one of the subtypes of lining, the appearance of which looks like a rounded log. The product resembles a log house and is used for interior and exterior work, both as the main material and as decoration for individual elements. The main advantage of a block house is:

- durability;

- high thermal insulation and sound insulation;

- high strength;

- ease of installation;

- fire resistant due to special processing fire retardants and antiseptics;

- Impact resistant and not deformed.

Lining

Is economical and the best option for home decoration. The following tree species are used in production: pine, spruce, oak, alder, linden. The main advantages of the material include:

- long service life;

- high resistance to mechanical damage;

- ease of installation;

- high sound insulation;

- Possibility of painting or tinting.

But the disadvantages include the possible appearance of insects and fungus. The photo shows clapboard lining of the attic space.

Important! To protect the tree from attacks by rodents and insects, it is necessary to eliminate the presence of gaps when laying. The resulting free space is filled mineral wool, which can also perform the function of additional sound insulation.

Decking

- loggia or balcony;

- terrace.

The use of decking will allow you to perform finishing and decorative works. The material is stable, not afraid of open space, resistant to mechanical damage and scratches. Care terrace board Quite simple and involves wet cleaning. An example of laying decking on the porch of a house

Decorative wood wallpaper

Decorative wallpaper for walls is made from valuable wood. In addition to wood, they contain veneer, which is carefully glued onto thick paper. The advantage of wallpaper is the ability to paste it onto radial areas of the room.

For information! For long term operation, wooden wallpaper must be treated with wax, varnish or oil. Wallpaper can change its color and size (swell) when exposed to direct sun rays or water.

By decorating the room with wooden wallpaper, the room will give a chic and original look. An example of an original living room decorated with wooden wallpaper

Wood panels

In the production of panels, tree species such as alder, maple, cedar, and oak are used. Wall decoration made of wood looks elegant, unusual and noble. The panel has three layers with a veneer surface made from rocks valuable trees. To make it more effective appearance to increase their service life, the panels are coated with special wax or acrylic varnish.

For information! Wooden panels those treated with wax are considered the most environmentally friendly in contrast to acrylic processing. Experts recommend using panels treated with wax to decorate wooden walls in a child's room or bedroom.

There are also tinted panels; in the manufacture of such panels for walls, wood is used from solid pine. This material is quite easy to install and has a lower price. Caring for the panel is not difficult; regular wet cleaning without using chemicals. The photo shows the interior of the living room made using wooden panels

Parquet and floor boards

Floor boards and parquet are used for interior finishing and laying floors made of laminate, parquet and other materials. This material requires a carefully flat surface to work with. Thanks to a large selection of designs, color palette and textures of products, floor boards goes well with various design solutions. The photo shows a living room decorated in Scandinavian style using floor boards

Important! The board or parquet will last longer if you choose a suitable substrate and carry out proper care behind the floor covering.

Glued laminated timber

Glued laminated timber is a universal material. It is widely used for performing external work on house cladding, as well as for interior works for the construction of architectural structural elements. It is used for the device:

- ceiling beams;

- devices of railings and openings;

- decorating stair railings;

- decorative partitions.

Glued laminated timber is a fairly strong material, resistant to damage and not afraid of deformation or cracking. The photo shows a house covered with laminated timber

Gusvarblok

This modern material, having a huge amount various types profiles (more than ten thousand) and can fit perfectly with any interior. Gusvarblok panels are easily joined and mounted, and a hidden connection allows you to assemble correct drawing. The advantage of the product is:

- environmental friendliness;

- high quality sound and thermal insulation;

- easy care;

- long service life.

For information! You cannot install wood products immediately after purchasing them; they must acclimatize a little. The material should “rest” for about a week.

Manufacturers have taken care of a large selection of finishing materials for interior and exterior decoration of the house. Finishing wooden crafts They have a large selection of colors, textures, and shapes that allow you to implement any design solution.

Before you make a choice, remember that the walls of the house occupy a large area, unlike the flooring. Therefore, it is very important to perform high-quality and beautiful finish, which will emphasize the style of the room and give it a special personality.

The interior, made of wood and other natural materials in eco-style, is certainly one of the most popular today. This is not only a tribute to fashion, but also an understanding that it is the healthiest and closest to nature way of organizing a room.

Covering floors, walls, and other elements of the interior space with finishing materials made from natural wood is designed to make the room attractive, insulate it and protect it from excessive moisture.

When finishing natural wood inside the house, between the sheathing and the finishing surface, a multilayer structure with heat-insulating and sound-proofing qualities is usually placed.

Benefits of wood finishing

Provided it grows in ecologically clean areas, wood is one of the cleanest materials for finishing the interior of a home.

Coziness and comfort in the home

Wood can be used for any surfaces inside the house and serve as a material for:

- walls;

- gender;

- ceiling;

- flights of stairs;

- floors;

- door structures;

- window frames;

- decorative elements.

Wood finishing can create a special healthy microclimate in the home, in which all life processes proceed normally: sleep well, work, breathe. Unlike artificial materials emitting harmful fumes, the tree does not cause headache, as well as a feeling of chronic fatigue and can neutralize the harmful effects of other materials.

Wood reduces dampness in the room, prevents the development of bronchopulmonary diseases, as well as the appearance of mold and other consequences of excessive humidity.

Choosing wood for interior decoration

Before you start finishing work, you should decide on the choice of wood type. First you need to decide whether it will be coniferous or deciduous wood. Here the criterion will be operating conditions and wear resistance requirements. For rooms with excessive humidity (baths, bathrooms, saunas), you should choose coniferous wood. And well-ventilated ordinary rooms can be decorated with deciduous wood (alder, oak, linden).

It is necessary to choose the right material for the job

It is necessary to choose the right material for the job Lining

By lining we mean a collective concept that unites all finishing materials equipped with a locking system. Fastening is carried out using the tongue-in-groove method and can be “butt” or “overlapping”.

The peculiarity of the use of this material is its exceptional ease of installation, which allows you to complete the interior decoration of the house in a short time. Having information about the area and shape of the room that you plan to cover, you can accurately calculate required amount linings.

The material has practicality, versatility and high decorative properties, thanks to which it can be perfectly combined with any design direction. Cladding with clapboard can be carried out in vertical and horizontal directions.

With proper care and treatment, lining can last a very long time. Its popularity is only growing over time, not inferior to more modern finishing materials. In its production, carefully dried wood with both a smooth and untreated surface is used.

Advantages of lining:

Practical and versatile material

Practical and versatile material - naturalness;

- environmental friendliness;

- nice smell;

- unique appearance;

- hygroscopicity;

- ease of installation;

- availability;

- durability;

- thermal insulation and sound insulation.

Flaws:

- possibility of deformation;

- sensitivity to temperature changes;

- swelling from exposure to moisture.

The manufacturing quality of eurolining is strictly controlled at all stages. For its production, the highest grade raw materials are used, obtained from coniferous wood, often grown specifically for these purposes. Eurolining is divided into 1-3 quality classes and meets all accepted European standards.

The material is manufactured in accordance with European standards

The material is manufactured in accordance with European standards This material differs from ordinary lining in its precisely adjusted dimensions, as well as the presence of a special groove that provides ventilation and moisture removal. This design feature increases durability, prevents deformation and swelling of the cladding when used in a damp environment. The excellent quality of the material makes it possible to assemble with the smallest tolerances. Thanks to this, the result of the work is highly decorative.

In conditions industrial production The surface of the eurolining is coated with a special composition, which frees home owners from the need for additional treatment with paints and varnishes.

The difference between eurolining and conventional lining:

- significantly smoother surface;

- strict adherence to quality standards;

- minimum humidity level (12% versus 15-28% for lining);

- polyethylene packaging;

- the presence of a special protective coating;

- larger spike size;

- presence of a groove at the junction;

- more ventilation grooves.

Floor board

There are two varieties: solid board and laminated board. The first option is made from a solid mass, and the other is made from spliced pieces. In addition, the floorboard is divided into tongue-and-groove (having tongues and grooves) and non-tongue.

Wood flooring options

Wood flooring options There is a regular board and a Euroboard. The latter is manufactured using a special technology the latest equipment from high-quality raw materials in compliance with European standards. This board is quite expensive, but is of high quality. She has smooth surface, perfect shape, low humidity and completely free from defects (holes, knots, blue). The massive Euroboard is equipped with ventilation grooves to avoid deformation due to load distribution, eliminate the risk of mold development, and also increase service life.

Pros and cons of regular solid wood flooring

The material is environmentally friendly and easy to install

The material is environmentally friendly and easy to install Advantages:

- naturalness;

- environmental friendliness;

- speed and ease of installation;

- durability;

- beauty of the material;

- low thermal conductivity, sound insulation;

- healthy microclimate at home.

Flaws:

- Resin pockets are sometimes present;

- knots that reduce the quality of the board.

Also, one of the most important advantages of such a board is the possibility of its repeated restoration. It can be sanded up to 15 times, this extends its service life to at least 100 years.

In order for the floorboard to last as long as possible, you should choose a suitable substrate and follow simple rules for caring for it.

This material looks very noble in large rooms with good natural light.

Wooden block house

This material is used for interior and exterior decoration. It is practical, convenient, easy to care for, and at the same time looks very decorative. All these qualities, as well as environmental friendliness and affordable price material make it popular among consumers. A high degree of wood drying eliminates deformation, premature deterioration and cracking of the material. Treatment with antiseptics and fire retardants prolongs its full use.

To make a block house, wood of various species is used, but the most used types are larch and pine. A block house made of linden, birch or cedar looks very decorative.

Affordable and environmentally friendly material

Affordable and environmentally friendly material Various unattractive surfaces, such as concrete or brick, after finishing works with the use of a block house they look more than decent. The feeling of a solid facade is created due to the fact that its individual elements in the corners are joined with special corners.

A block house made of larch wood has a beneficial effect on the nervous system, as well as the cardiovascular and respiratory systems, due to the release of volatile substances by larch wood - phytoncides. This property completely covers the inconvenience when processing this hard, resinous material.

Imitation of timber will highlight the most cozy areas

Imitation of timber will highlight the most cozy areas This product is an effective material for interior decoration, allowing you to change the space of your home without drastic measures.

The material is not subject to deformation

The material is not subject to deformation Imitation of timber is produced using a special technology. It is first dried for 8-12 weeks using special cameras until almost complete evaporation of moisture and destruction of pests. Then the finished boards are sorted and cut. Manufactured in a similar way the panels are not subject to deformation, cracking, and also perfectly retain their original shape.

Thanks to the tongue-and-groove system, the assembly of the canvas from individual elements can be done with your own hands without special qualifications.

The cost of the product depends on the class and type of wood. The most popular materials are pine and spruce. They have a low price, and for some technical specifications even superior to more expensive species, for example, larch.

Imitation timber, like all natural wooden products, has low thermal conductivity and perfectly conserves heat in the room. If necessary, you can make additional thermal insulation of the building using layers of insulation placed between the finishing coating and the wall of the house.

Installation of wooden bars

Installation of wooden bars The variety of types of finishing materials allows you to create your own unique design home, and the wealth of colors will help you match it to almost any type of interior.

Interior wood decoration is an excellent contribution to a healthy lifestyle, an opportunity to surround yourself with elements of ethno-style created by nature itself.

This is a board with a rough, rough surface, which is obtained as a result of thin sawing or milling. Paint clings to such a rough surface better, so the paint coating lasts longer. Our guarantee for such painted finishing boards is 5 years.

Technological process painting Scandinavian boards:

Priming Aqua Primer 2907 / Teknol 3881 (brush machine)

- Applying the 1st layer of paint Nordica Eco 3330 (brush machine)

- Applying the 2nd layer of paint Nordica Eco 3330 (brush machine)

When painting this facade board, the original and interlayer sanding is not carried out, therefore the cost of such a board is cheaper than painting smooth, planed products presented in the next section. Such a paradox - the board is cheaper, but the durability is higher!

| Dimensions, mm | Painting | Price per m2 |

| Grade AB/C | ||

| ProfileUYV | ||

| 21*145(135)*6000 21*145(135)*4800 | No painting | 540 rub. / 290 rub. |

| Primed | 740 rub. / 490 rub. | |

| Painted | 1190 rub. / 940 rub. | |

| Buy | ||

| ProfileUYS |  |

|

| 21*145(135)*6000 21*145(135)*4800 | No painting | 540 rub. / 290 rub. |

| Primed | 740 rub. / 490 rub. | |

| Painted | 1190 rub. / 940 rub. | |

| Buy | ||

| ProfileUYL |  |

|

| 21*145(135)*6000 21*145(135)*4800 | No painting | 540 rub. / 290 rub. |

| Primed | 740 rub. / 490 rub. | |

| Painted | 1190 rub. / 940 rub. | |

| Buy | ||

| ProfileUYW (tongue+plank) |  |

|

| 21*145(135)*6000 21*145(135)*4800 | No painting | 540 rub. / 290 rub. |

| Primed | 740 rub. / 490 rub. | |

| Painted | 1190 rub. / 940 rub. | |

| Buy | ||

| ProfileOblique planken |  |

|

| 21*145(130)*6000 21*145(130)*4800 | No painting | 540 rub. / 290 rub. |

| Primed | 740 rub. / 490 rub. | |

| Painted | 1190 rub. / 940 rub. | |

| Buy | ||

| ProfileUTF (imitation timber) |  |

|

| 21*145(135)*6000 21*145(135)*4800 | No painting | 540 rub. / 290 rub. |

| Primed | 740 rub. / 490 rub. | |

| Painted | 1190 rub. / 940 rub. | |

| Buy | ||

| ProfileKM4R (straight planken) |  |

|

| 21*95/120/145*6000 21*95/120/145*4800 | No painting | 540 rub. / 290 rub. |

| Primed | 740 rub. / 490 rub. | |

| Painted | 1190 rub. / 940 rub. | |

| Buy | ||

| ProfileKM2R |  |

|

| 21*95/120/145*6000 21*95/120/145*4800 | No painting | 540 rub. / 290 rub. |

| Primed | 740 rub. / 490 rub. | |

| Painted | 1190 rub. / 940 rub. | |

| Buy | ||

| ProfileKM |  |

|

| 21*95/120/145*6000 21*95/120/145*4800 | No painting | 540 rub. / 290 rub. |

| Primed | 740 rub. / 490 rub. | |

| Painted | 1190 rub. / 940 rub. | |

| Buy | ||

This section of the price list presents products with a perfectly smooth painted surface of the board, the so-called “furniture quality”. First, such a board must be sanded on a calibration grinding machine and then painted. Since in this case there are two additional operations: primary sanding and interlayer sanding, the cost of this finishing board is higher than the Scandinavian one.

- Packing through foam film and loading

To touch up the cuts (ends) of the board, paint and varnish is provided (free of charge)

| Dimensions, mm | Painting | Price per m2 |

| Grade AB/C | ||

| ProfileUYV | ||

| 21*145(135)*6000 21*145(135)*4800 | No painting | 540 rub. / 290 rub. |

| Painted | 1440 rub. / 1190 rub. | |

| Buy | ||

| ProfileUYS |  |

|

| 21*145(135)*6000 21*145(135)*4800 | No painting | 540 rub. / 290 rub. |

| Painted | 1440 rub. / 1190 rub. | |

| Buy | ||

| ProfileUYW (tongue+plank) |  |

|

| 21*145(135)*6000 21*145(135)*4800 | No painting | 540 rub. / 290 rub. |

| Painted | 1440 rub. / 1190 rub. | |

| Buy | ||

| ProfileOblique planken |  |

|

| 21*145(130)*6000 21*145(130)*4800 | No painting | 540 rub. / 290 rub. |

| Painted | 1440 rub. / 1190 rub. | |

| Buy | ||

| ProfileUTF (imitation timber) |  |

|

| 21*145(135)*6000 21*145(135)*4800 | No painting | 540 rub. / 290 rub. |

| Painted | 1440 rub. / 1190 rub. | |

| 28*193(185)*6000 | Painted | 1640 rub. |

| Buy | ||

| ProfileKM4R (straight planken) |  |

|

| 21*95/120/145*6000 21*95/120/145*4800 | No painting | 540 rub. / 290 rub. |

| Painted | 1440 rub. / 1190 rub. | |

| Buy | ||

| ProfileKM2R |  |

|

| 21*95/120/145*6000 21*95/120/145*4800 | No painting | 540 rub. / 290 rub. |

| Painted | 1440 rub. / 1190 rub. | |

| Buy | ||

| ProfileKM |  |

|

| 21*95/120/145*6000 21*95/120/145*4800 | No painting | 540 rub. / 290 rub. |

| Painted | 1440 rub. / 1190 rub. | |

| Buy | ||

The technological process of painting planed products consists of the following operations:- Grinding or Brushing (appropriate machine)

- Priming Aqua Primer 2907 / Teknol 3881 (spraying)

- Applying the 1st layer of varnish Aquatop 2600 (gl/mat) / paint Nordica Eco 3330 (spraying)

- Intermediate grinding (machine, grain P 220)

- Application of the 2nd layer of varnish Aquatop 2600 (glossy/mat) / paint Nordica Eco 3330 (spraying)

- Packing through foam film and loading

To touch up the cuts (ends) of the board, paint and varnish is provided (free of charge)

| Dimensions, mm | Painting | Variety | Price per m2 |

| ProfileOblique planken |  |

||

| 20*140(125)*4000 20*115(100)*4000 | Painted | AB | 1890 rub. |

| A-Prima | 2190 rub. | ||

| Extra | 2590 rub. | ||

| Buy | |||

| ProfileStraight planken |  |

||

| 20*140*4000 20*120*4000 20*90*4000 | Painted | AB | 1890 rub. |

| A-Prima | 2190 rub. | ||

| Extra | 2590 rub. | ||

| Buy | |||

| ProfileImitation of timber |  |

||

| 20*140(135)*4000 | Painted | AB | 1890 rub. |

| A-Prima | 2190 rub. | ||

| Extra | 2590 rub. | ||

| Buy | |||

| ProfileTerrace deck board |  |

||

| 28*140*4000 | Painted | AB | 2040 rub. |

| A-Prima | 2540 rub. | ||

| Extra | 2840 rub. | ||

| Buy | |||

| ProfileCorduroy decking board |  |

||

| 28*140*4000 | Painted | AB | 2040 rub. |

| A-Prima | 2540 rub. | ||

| Extra | 2840 rub. | ||

| Buy | |||

The best sellers in this section are lining and imitation timber. Calm lining is often used to sheathe ceilings, and imitation timber is used for interior frame walls in houses made of timber.

In order to stand out and implement a non-standard design idea, we invite you to consider other interesting profiles. For example, an oblique plank or a tongue-and-groove analogue of UYW, as well as a UYS profile for vertical finishing.

The technological process of painting planed products consists of the following operations:- Grinding or Brushing (appropriate machine)- Priming Aqua Primer 2900 (spraying)

- Applying 1st layer of wax/varnish/paint Teknovax 1160 / Teknocoat Aqua 2550 (spraying)

- Intermediate grinding (machine, grain P 220)

- Application of the 2nd layer of wax/varnish/paint Teknovax 1160 / Teknocoat Aqua 2550 (spraying)

- Packing through foam film and loading

To touch up the cuts (ends) of the board, paint and varnish is provided (free of charge)

In interiors, the use of aged boards is very popular, which is obtained by layer-by-layer application of paint and varnish on a brushed board. Please note that the cost of a simply sanded board and a brushed board is the same.

| Dimensions, mm | Painting | Variety | Price per m2 |

| ProfileLining calm |  |

||

| Pine-Spruce | |||

| 15*135(130)*6000 | Painted | AB | 1290 rub. |

| 21*145(135)*6000 | Painted | AB | 1390 rub. |

| Larch | |||

| 14*138(132)*4000 | Painted | AB | 1640 rub. |

| A-Prima | 1940 rub. | ||

| Extra | 2240 rub. | ||

| Buy | |||

| ProfileImitation of timber |  |

||

| Pine-Spruce | |||

| 17*145(135)*6000 | Painted | AB | 1290 rub. |

| 21*145(135)*6000 | Painted | AB | 1390 rub. |

| 28*193(185)*6000 | Painted | AB | 1590 rub. |

| Larch | |||

| 20*140(135)*4000 | Painted | AB | 1840 rub. |

| A-Prima | 2140 rub. | ||

| Extra | 2540 rub. | ||