Relatively recently, an unusual technology of wooden housing construction was developed in Austria, in which the beam is not located in the usual horizontal way, but is set vertically. Such an unusual arrangement of walls has proved to be very beneficial from various points of view, so such houses are becoming more common.

This technology is beneficial from both a constructive and environmental point of view.

Advantages of vertical timber houses

A house made of vertical timber not only looks unusual, but also has a number of practical advantages, thanks to which this technology from Austria has spread all over the world.

What are the features and main advantages of such houses?

- Everyone knows that one of the main disadvantages of wood is a long shrinkage, due to which construction has to be stopped for almost a year after the walls are erected. When the beam is vertical, there is no shrinkage, which means that you can immediately continue the construction of the roof and proceed to the interior decoration. Less time - less construction costs, so the Austrian technology was also profitable;

- High degree of energy saving. The designers calculated that when the logs are perpendicular to the direction of the wind, they are much better at preventing drafts and heat loss;

Important!

Right assembled structure has 1.5 times less thermal conductivity than a conventional house made of glued laminated timber, and 2 times less than a house made of logs.

Low heat losses help to save on heating and create a comfortable atmosphere at home.

- The technology allows you to enjoy all the benefits of a tree, moreover, it is located the way it grows in nature. Synthetic sealants or glue are not used, there is no need to lay interventional insulation, as in the construction of a log cabin. The house will have a pleasant and healthy atmosphere, especially if it is made of cedar or larch;

- Houses made of vertical timber are easy to install and fast to assemble. Even a large building can be assembled in just a few months. The beam has a small weight, so there are no problems with its transportation and delivery to the site. (see also article)

In addition, it is worth noting the strength and reliability of a house made of vertical timber. Thanks to this arrangement, the material is exposed to minimal moisture and does not suffer even from heavy snow loads..

It is no coincidence that the technology was developed in the highlands of snowy Austria, where climatic conditions are almost as harsh as in Russia. Vertical beam - new technology wooden housing construction, which, perhaps, will be able to gain the widest distribution.

Material requirements:

- The beam should not have any knots and defects, as they reduce the strength of the walls;

- It must be perfectly dry. The humidity level does not exceed 12%. First, it dries naturally, on outdoors, and then placed in special camera.

Of course, the price of such material is quite high, but in return you will get a warm and comfortable home, and the savings are achieved due to the minimum interior decoration.

The beam, located vertically, retains all its natural beauty, therefore, both from the outside and from inside the house will look great. The completely dried material is light in weight, so you can get by with a minimum of equipment on the construction site.

Advice!

The elements that make up the walls can easily be lifted by one person.

Thanks to this, you can try to build such a house with your own hands, without resorting to the help of specialist builders.

How to build a building from a vertical beam?

Construction can be completed in 1 season, and you can do without the minimum amount professional help. One of the most difficult operations that cannot be handled on your own is the preparation of timber for construction.

With the help of a special planing and milling machine, the trunks are shaped into a rounded beam, after which special grooves are machined into them, with the help of which the structural elements will be fastened together.

Preparation of an architectural project

Such buildings can have a very large design variety, since any number of timber can be placed vertically in any direction. Its length can also be different, so different ceiling heights are possible. You can use one of the standard projects wooden houses, or you can order or create your own individual, unique building, which will become a decoration of the street and the pride of the owner.

The vertical dimensions of the walls made of timber can reach 3 meters. The wood must have a minimum diameter of 180 mm, the wall of the house may have a thickness of more than 300 mm. This will reliably protect the interior from both cold and wind. When all the elements for assembly are ready, they can be transported to the site.

Foundation pouring

Another difficult stage is pouring the foundation for the future home. Since it is light in weight, a particularly strong foundation is not required. Usually they use the traditional tape variety, which allows you to equip basement. A columnar version is also possible, in which case the pillars are connected by a single harness, on which the logs are installed.

A pit is being prepared on the site, after which a special strip foundation with grooves on which the beam will be installed in a vertical position. The foundation must be completely dry, the beam is placed only on a durable layer of waterproofing to exclude the possibility of contact with moisture.

To calculate required amount materials for the strip foundation, you can use the calculator:

building construction

Instruction and general principle construction is somewhat reminiscent of the children's designer, since the beam is connected into a solid system using grooves in strict accordance with the plan. So that the logs at the beginning of construction do not deviate from vertical plane, they line up in level and are fastened together with dowels. The work can go very quickly, since one beam is simply attached to another and joined with protrusions and grooves.

At the same time, the corners turn out to be monolithic, there are no unique details. The constructor consists of the same elements, and therefore it is assembled very quickly. Small air cavities remain inside the structure, which increases the heat-insulating properties of the house. Once the walls are assembled, you can start arranging the floors and roofing, and then - to all the details of the finish.

The vertical bar is fairly new building technology which came from Austria. Houses from a vertical bar, projects and prices for them are quite democratic and diverse.

Architectural bureau ARXY specializes in design and construction, offering exclusive solutions and favorable terms of cooperation. If you need it, feel free to contact us.

Features of vertical timber houses

The main feature of such houses is the vertical orientation of the timber and the fact that no insulation or glue is used during the construction process. The structure is entirely made of natural wood. Vertical arrangement bars solves such typical problems wooden buildings as shrinkage and shrinkage. By technological characteristics such a house is closer to stone. At the same time, houses made of vertical timber, projects and prices for their implementation are incomparably lower.

The cuts along the beams do not allow the tree to deform, they are also responsible for the high thermal properties of the material. The mass of logs is very small, which facilitates the installation process and reduces the cost of construction equipment and expensive foundations.

ARXY specialists warn that the installation technology of such houses is that it is suitable for the construction only full floors no attic.

2 basic mistakes of typical projects of houses from a vertical bar:

Our architectural bureau is engaged in individual design of residential buildings, offering only original solutions created personally for a specific customer. If you are interested in houses made of vertical timber, projects and prices are formed individually, remaining in the affordable segment.

ARXY architects know for sure that there are many subtleties that are almost never taken into account in typical projects. Their main problem and a very common mistake in designing houses is that designers use the same schemes as when designing apartments:

● No buffer zone for heat. Leaving the hallway of a private house in the winter months, you do not find yourself on a heated staircase, but directly on the street.

At sub-zero temperature the first floor will be exposed to cold and the cold can be felt in a few seconds in the farthest corner.

● Irrational use of space. A typical mistake in the projects of houses from a vertical beam is active use corridors, which are difficult to do without in an apartment, but in a house they only clutter up the space. By themselves, they do not carry a functional load, but they take away the useful area of \u200b\u200bthe house and do not allow creating an open and more attractive space.

Even the best standard project will not take into account the characteristics of the soil on your site, preference in terms of organization functional areas and many other nuances. Moreover, the creation of individual projects always results in savings.

Why are we better?

Our architectural bureau offers a full range of services from project creation to turnkey construction. This is a profitable offer that will allow you to save money, shorten the project implementation time and fully control the process.

For all types of work, we have licenses and permits from the SRO. And a team of engineers, designers, architects and designers will cope with any task. We also offer our clients:

● 50% discount on interior design when ordering construction in our office;

● free architectural supervision;

● free 3D tours of the project.

If you are planning to build a house from a vertical beam, projects and prices can be discussed by calling us at the phone number listed on the site.

You can also order a measurer's visit to the site right now for free.

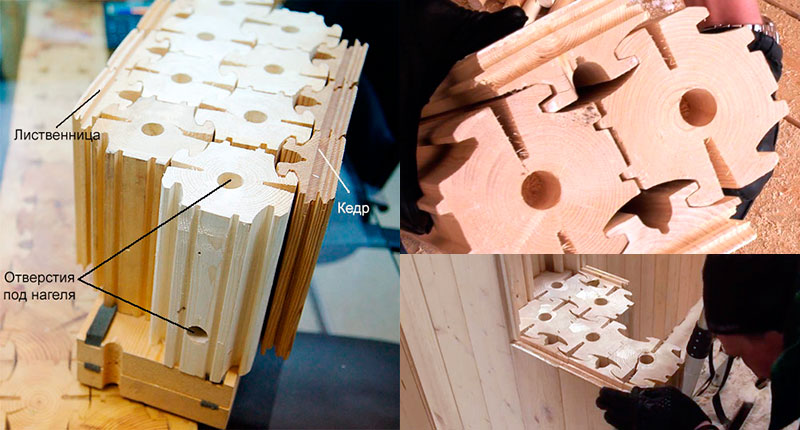

There are several technologies for wooden housing construction, including the new Austrian Naturi technique. A vertical beam is used to erect the box. Wooden elements are made on special equipment. The complex geometric shape provides for the presence of special cuts located on four sides, a tongue-and-groove connection, and holes for dowels. Such buildings differ from the classic timber options in assembly technique, performance and appearance.

Cottage built using vertical timber technology

Construction technology

Several layers of waterproofing are laid on the finished foundation to prevent moisture from entering the wooden elements. Racks are mounted in a vertical position to the lower and upper trim. The bottom row consists of a backing board laid in 2 rows. Holes are drilled in it for wooden dowels round or square section 25 mm. The upper trim of boards with holes is fixed on beam supports located at some distance from each other. The installed vertical racks are connected to each other using such dowels, which are located along the length and on both sides - 2 fasteners in the upper part and 2 in the lower.

The docking points are closed from the inside and outside with curly strips, which are made of different breeds wood. For outer skin moisture-resistant and non-rotting larch is used, cedar is suitable for the interior, which has useful properties. Finishing elements are fastened with a tongue-and-groove connection. The end result is a massive and particularly durable wooden box resistant to wind and vertical loads.

On our website you can get acquainted with the most popular projects from construction companies presented at the exhibition of houses "Low-Rise Country".

Features of vertical timber houses

Increasingly, a vertical bar is used to assemble wooden houses. The new technology of wooden housing construction has a number of features:

Assembly uprights performed similarly to the Lego constructor. The high precision of the manufactured elements guarantees the speed of erection and the correct geometry of the wooden building.

Naturi technology is based on the use of environmentally friendly materials - no boxes are used in the construction and decoration adhesive compositions, artificial insulation.

The tree gives off not only heat, but forms air inside the room, which is saturated essential oils beneficial effect on the human respiratory organs.

elevated thermal insulation characteristics buildings are achieved by air gaps formed inside the vertical elements. Due to the complex shape of the profile and the tight connection of all elements, cold bridges are excluded.

Vertically located beam has a low shrinkage rate - 80% less compared to other types of materials. Such a feature wall material from wood is explained by the fact that dimensional changes occur along, and not across the fibers. The walls are not subject to deformation even with seasonal temperature fluctuations.

The minimum shrinkage of the vertical beam allows you to start finishing work almost immediately after installation

No need to create additional insulation, finishing outside and inside, thereby reducing the overall cost of construction.

You can move into a house from a vertical beam immediately after finishing work is completed.

The durability of a house from a vertical beam depends on the quality wooden elements. The main thing is not only the absence of defects and knots, but also full compliance technological process drying. First, the timber is given natural drying under the influence of the natural environment, after which it enters a special chamber, where the moisture content of the wood is brought to 14% (not higher). The material is delivered to the construction site in thermally insulating packaging. After installation, the bars gain moisture from the air, swell and adhere to each other tightly, so that they cannot be separated. Wooden houses using Naturi technology cannot be dismantled.

Video description

Visually about the Naturi technology - houses from a vertical beam, see the following video:

The construction market has a large selection of house designs and prices

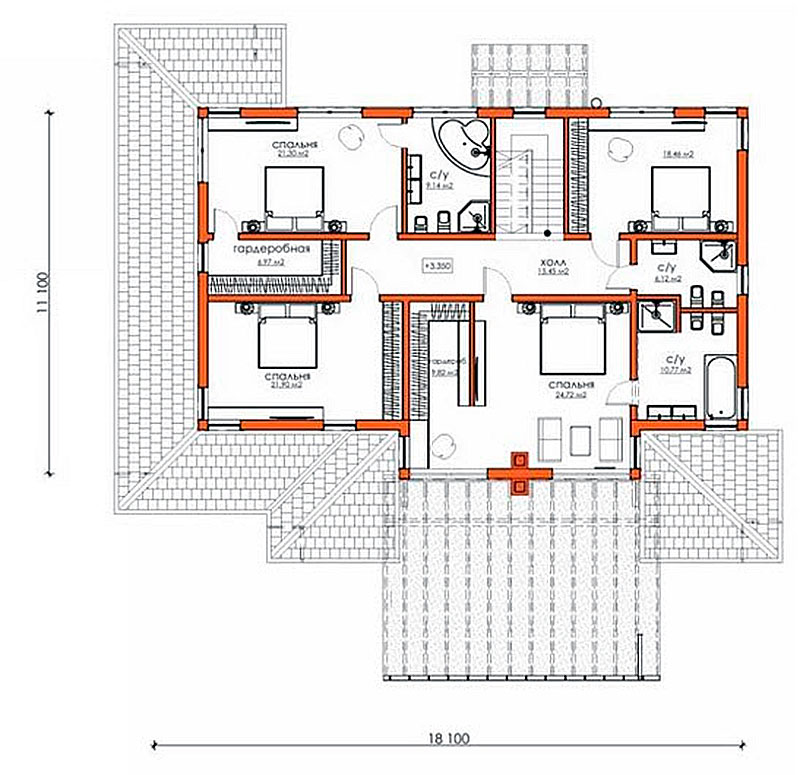

Buildings are being built according to Austrian technology no higher than 3 floors, more often erected two-storey house from a bar. Designers offer a wide variety of forms of houses from a vertical bar. Projects and prices are so diverse that they can satisfy the needs of both a large and a small family of two. The best option houses to choose from finished projects taking into account the features of the landscape and the size of a particular territory. We offer to view several options for a house made of timber: projects, photos are taken from the websites of construction companies.

Two-storey house with an attic

Two-storey house 9x15 m attic floor under the roof is made of vertical timber using Naturi technology. The base is a strip foundation. Exterior trim elements made of larch 200x50 mm in size. load-bearing walls And internal partitions section 200x200 mm are made of conifers. The interior trim is made of cedar planks. The roof is metal. The building is warm and spacious, suitable for a large family of 5-6 people.

House with a balcony

Project two-story house 8x12 m with a balcony made of vertical timber, made according to Austrian technology. Foundation monolithic slab. A larch underlayment board with a section of 200x50 mm is laid along the perimeter of the 1st floor. The material of the outer walls and internal load-bearing partitions consists of conifers. Vertical columns 200x200 mm in size. Humidity of a bar is not less than 12-14%. Floor beams 100x200 mm with a pitch of 600 mm in the axes. roofing material metal tile. The house is intended for a family of 3-4 people. Such a project, for example, is offered by IC "White Crane" - timber houses are its specialty. The price of the project is from 20,000 rubles, if you order turnkey construction, then the design is done free of charge.

Cottage with covered terrace

The original project of the house - perfect solution for a site with a slight slope. Number of floors - 2, total area - 329 sq. m., terrace area - 102 sq. m. All external walls made according to Naturi technology from a bar 200 mm thick. Internal walls- frame execution. The project provides for 3 bathrooms, a garage, a shed. The residential building is bright and spacious. It can comfortably accommodate a family with 2-3 children and family members of the older generation.

Two-storey house with a covered terrace on a slope

Cottage with a combined roof: flat and shed

Modern residential building for permanent residence turnkey with large windows 245 sq. m. Terraces occupy an area of 82 square meters. m. Ecological and functional housing stands out for its original architecture. The residential building can be used for permanent residence or as a summer residence. Suitable for a family of 2-3 people.

The price for the wall kit is from 3,560,000 rubles.

And if you plan a very small housing, you can build a house from a 6x6 timber, such houses are usually chosen for summer cottages, where a house is needed to take a break from the bustle of the city.

Video description

See the following video for more about houses made of vertical timber:

On our website you can also get acquainted with the most from the construction companies presented at the exhibition of houses "Low-Rise Country".

Conclusion

Residential buildings made of vertical timber are light, high-strength and comfortable for both seasonal and permanent residence. The assembly of the walls is completed in a few weeks. The technology is economical and profitable, which has become the main reason for its popularity among developers.

Construction of houses from a vertical bar - innovative technology gaining popularity all over the world. The Ecodom98 company offers to buy a house from a vertical beam at affordable prices.

There are many technologies wooden construction. Recently, thanks to the research of Austrian architects, another one has been added to them. We are talking about a unique construction technology based on a vertical bar. The Austrians decided to follow the example of nature, which arranges tree trunks vertically. It turned out that this is much more profitable, and for several reasons at once.

What are the advantages of vertical timber houses?

- No shrinkage. Shrinkage is a major problem in timber construction. Depending on the type of wood used, you have to wait from several months to one and a half years. The vertical beam completely excludes shrinkage! Roofing can begin immediately. internal work and, finally, housewarming.

- Energy efficiency. Modeling has shown that placing logs perpendicular to the direction of air flows provides better protection from drafts and prevents heat loss. It has been experimentally established that a house made of a vertical beam has half the thermal conductivity than similar houses made of a frame.

- Environmental friendliness. The construction technology based on a vertical beam does not require the use of synthetic sealants, interventional insulation, various adhesives etc. There will always be a healthy atmosphere in the house!

- Price. For a house made of vertical timber, the price is only 20% higher than the standard frame technology. You should also take into account the savings due to the reduction in construction time.

Vertical timber houses, the best projects and affordable prices

Would you like to live in a modern cozy cottage? Here you can buy a house from a vertical bar at the lowest price. The company's website presents projects carefully selected by us over 18 years of successful work on the market. Any of them can be yours!

A wooden house is nothing new in the housing market. Moreover, wooden houses they were the first to appear after caves and dugouts, and their construction, it would seem, has been honed for millennia so that it is impossible to come up with a new one in principle. But innovative products such as vertical beams have changed the idea of traditional wooden housing in better side, and today houses made of vertical timber are reviving the faded interest in wood as such.

Naturi technology

This technology, called “naturi” by specialists, is already about a hundred years old, and during this time its foundations have constantly changed and improved. On this moment a vertical beam as a product is a very complex element, consisting of curvilinear joints along special cuts in wood, providing a strong connection, minimal shrinkage of the structure, immunity to moisture and the absence of cracks and deformations during the operation of a loaded building. According to the load calculations, a house made of vertical timber, built according to the naturi method, can be built 1-3 floors high without fear of its deformation or shrinkage, and the aesthetic texture of the timber allows not to carry out exterior finish walls and ceilings, with the exception of the own preferences of the owners of the house. The drawings above and below show an individual project of a cottage built using naturi technology, as well as its floor plan.

Due to the complex section of the beam (figure below) cold air meets on its way an insurmountable obstacle in the form of labyrinths that keep the heat in the house and give the structure the highest strength. Connect individual elements beams in several places complex elements"groove-plank". Along the plane of the wall, there is an additional strengthening of the fastening of the beam with dowels (tongues), along the top and bottom of each beam element.

Also, the fastening of the timber is reinforced with tongues, they are placed along the upper and lower trim of the timber, to which the main supporting structure is attached. The timber is connected to each other along the entire wall using the “groove to groove” method, plus additional reinforcement is made with dowels in the horizontal plane. Standard Thickness vertical beam - ≥ 180 mm. Such wooden constructor allows you to assemble and prepare for the settlement of the house for 4-5 months. Completely erected facility with an area of 200 sq. m.

Positive and negative aspects of technology

- The shrinkage of a building built according to the naturi method is 50-90 times less than in a house made of horizontal timber;

- Dowels in the walls increase the strength and stability of the building;

- Any timber absorbs moisture, but when it swells, vertical timber only improves its wind and sound protection characteristics, increases heat saving in the house;

- The natural inflow and outflow of air masses is supported, which means that there is no need for forced ventilation;

- A profiled vertical beam allows you to create projects of any architectural complexity;

- Assembling a house according to the Naturi method is quick and uncomplicated due to the use of unified elements made in advance at the factory;

- It is not necessary to caulk and insulate the walls;

- It is possible to build a house that uses a vertical beam, a new technology of wooden housing construction, both in winter and in summer, in any weather.

Minor disadvantages:

- Due to the high density of interfaces, after some time of operation, due to the humidity of the air, the walls swell, and it will be problematic to dismantle such a house to move to another place;

- Modern projects using this technology are difficult to implement without professional skills.

How timber is made

All projects of houses from a vertical beam involve the use of factory longitudinal cuts to prevent deformation of the elements and the entire structure. The bar is placed in a vertical position and connected by grooves and ridges, as well as dowels into a monolithic structure. Before starting construction, you should make sure that the moisture content of the wood is low and that there are no defects in the timber. The timber should not be wet by more than 12%.

- Wood in the form of logs is sorted by indicators of suitability and quality;

- The logs are sawn to the required size, the blanks are dried using a special technology;

- The beam is milled and drilled for dowels according to design calculations;

- Finished products are stacked and packed for transportation to the construction site.

Due to the complex technology, the prices for such a beam will always be higher than the prices for solid or profiled beams, but the end result levels out all costs.

Design and installation

Beam using naturi technology is a universal element that allows you to build buildings of any geometric and architectural complexity. It is not necessary to use wood of the same species for construction - you can take different ones, which will give the house comfort and increase its functionality.

Both delivery and warehousing, storage and subsequent installation of walls are carried out without the involvement of special equipment and additional labor.

The beam on four sides is equipped with complex-shaped grooves that make it difficult for outside air to enter the premises, which automatically makes the house much warmer compared to buildings made from other building materials.

Assembly steps:

- The first stage of construction is the construction of the foundation and the laying of the strapping on it for the subsequent fastening of the wall beam;

- The tongues with which the strapping and walls will be fastened are inserted into the holes of the strapping and into the beam of the walls;

- The end surfaces are connected by horizontal tongues at the top and bottom;

- As the walls are raised, cladding elements and openings for windows and doors are built into the factory grooves.

For waterproofing wooden timber walls from excessive moisture, several layers of roofing material or thick roofing material are laid on the concrete or brick of the base of the house. polyethylene film, and on top - strapping boards treated with antiseptic substances 50 mm thick and up to 250 mm wide. A horizontal bar measuring 250 x 100 mm is attached to this lining belt, and a vertical bar (on tongues) is already attached to it on one side, and on the other, it is attached to the foundation for anchor connections.

Boards are laid on the lining belt in two rows - for strapping, and holes are drilled through their factory holes in the lining wood, into which dowels are inserted. A timber for erecting walls will be mounted on the dowels. The upper belt is built in the same way.

Such a rather complex technology makes building a house more expensive, but the building itself will be stronger and more flexible at the same time - resistant to various kinds of deformations and multi-vector loads. The temperature and humidity regime of operation of such a house immediately enters a phase of stability, which continues throughout the life of the building. A house kit made of a vertical beam, manufactured at the factory, consists of the following parts and elements:

- Profiled timber of complex shape, dried using a special technology, with grooves, ridges, holes for dowels;

- profiled wooden details and elements for exterior and interior decoration and surface decoration;

- Boards prepared for assembly for mounting the top and bottom strapping– with holes for interfaces with the upper and lower joining structural elements; Domokomplekt wooden log house

- Vertical assembly of wooden elements, which is designed to completely minimize the effects of shrinkage of the building during the first months of operation;

- The high accuracy of manufacturing the beam itself, milled holes and recesses, elements of the "groove-groove" system and holes for dowels can significantly speed up the installation of the building, since it is not necessary to combine and control the accuracy of connecting all elements and parts - the process has been tested at the factory, and the builders only assemble the constructor according to the attached project drawings;

- Drying of wood for the manufacture of timber, as well as drying of finished timber, takes place according to a special technology, which subsequently ensures the solidity of the walls when they swell from atmospheric moisture.

Three main features of Naturi technology:

The main difference between the NATURI technology and the construction of houses from glued or profiled timber is the complete environmental friendliness of the project, which in Lately highly valued by the consumer.

The initial raw material of the naturi technology is thin (from 80 mm) trunks of coniferous trees, which are pre-treated with the removal of wood to the core. The blanks are dried first in natural conditions - in open space and without direct access sun rays, and then - in a special dryer until the moisture content of the wood drops to the required 12%. Thus, blanks of standard lengths of 2.5, 3.0 and 6.0 meters are of high strength, they do not rot, are not damaged by insects, and absorb moisture evenly and slowly.

Except softwood, V individual projects you can order larch or cedar to improve not only the operational parameters of the building, but also its appearance.