Not so long ago, a deck chair was considered exotic, and only wealthy people could afford it. We saw sun loungers in colorful magazines and American films, but even with a strong desire, an attempt to buy something like this for ourselves would have turned out to be a failure - there simply were no sun loungers for sale.

Well, everything passes sooner or later, and the information revolution generously endows us with new opportunities. Now anyone can find on the Internet a manual on how to make a sun lounger with your own hands. However, such plans are often difficult to implement, especially for a beginner. They require the use a large number expensive tool, and therefore for many remain unfeasible.

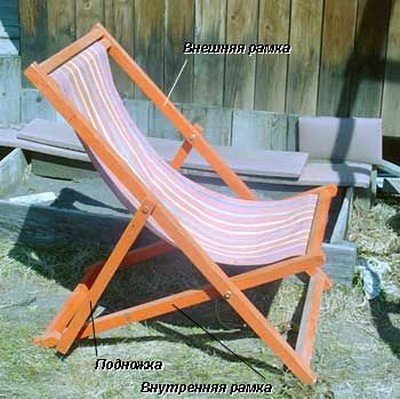

This master class is a pleasant exception to the rule. The deck chair presented by the author has a simple design and a clear system of folding and adjusting the backrest. If you approach the issue of choosing materials correctly, you will need a very modest arsenal of power tools and in last resort, you could easily borrow some of them from friends and acquaintances.

In addition, given the fact that the deck chair is made of natural wood, it can easily be used at home as well, instead of a couch or armchair in the living room. It quickly folds and unfolds, has a completely finished appearance. A beautiful textile mattress will complement the image, and the deck chair will perfectly fit into the interior of your home.

In order to make a deck chair with your own hands, you will need:

Materials:

Pine board 20 - 30 mm thick;

- slats with a section of 30 x 30 or 40 x 40 mm for the manufacture of a backrest folding system;

- natural or mineral oil for woodworking, drying oil or varnish for woodworking;

- screws and small nails;

- glue for gluing wood materials;

- metal one-piece loops for fixing the back: two larger ones and a smaller pair;

- a ready-made mattress with ties for fixing it or fabric, batting, foam rubber and threads for its manufacture.

Tools:

Miter saw, circular saw or wood saw;

- a grinder if you are using old or unpolished boards;

- screwdriver or Phillips screwdriver;

- electric drill;

- a clamp with a device for drilling pocket inclined holes (optional, but greatly facilitates the work);

- paint brushes;

- construction tape measure and square;

- pencil.

Step One: Sketch and Layout the Chaise Longue

A product layout is simply necessary if it itself consists of a large number of parts. It will not allow you to get confused in their countless list and will significantly speed up the entire work process. In addition, you will have the entire list of parts and their exact size. Well, without this, then?

But everything is preceded by a sketch. This sketch on a sheet of paper by hand gives rise to an idea and lays the main outlines of the image of the future product. That's where you should start.

In your case, the computer layout of the deck chair is already ready and you can safely take all the dimensions indicated in this master class as a basis. But first, write down on paper the entire list of parts that you have to make. Specify their sizes opposite and only after that proceed to work.

Step two: making parts

The detailing you have collected should be transferred to the material in the form of markings. Use a pencil for this to easily correct crept in errors. Also use a construction square. Especially if you plan to resort to help for sawing boards. hand saw. It will allow you to mark angles at 45 and 90 degrees, and accuracy is never superfluous.

So, mark up the parts and start making them. Saw the boards into pieces of the length indicated on your list. You will need:

Two longitudinal frame parts 1850 mm long;

- five transverse frame parts 470 mm long;

- four blanks for legs 280 mm long;

- four - five boards for the base of a deck chair 1270 mm long;

- two side long boards for the base of a deck chair 190 mm long;

- two small slats for supporting the backrest when folded, 580 mm long;

- three bars for the manufacture of the backrest 43 mm long;

- four - five boards for the base of the back;

- two slats for the backrest folding system, 230 mm long;

- one horizontal rail for the backrest folding system, 460 mm long;

- six small pieces of rail for the backrest folding system - three on each side.

All indicated dimensions should be specified, since the author indicated them in inches. They also depend on the thickness of the boards you are using. For sizing in your case, always start with total values and gradually move on to smaller details.

Step three: assembling the sun lounger

Start by assembling the deck chair frame. Remember that it is customary to assemble any frame with screws. This ensures the relative strength of the entire structure. However, it often happens that screws alone are not enough. Then glue is also used. Such combined connections serve very well and do not require repair for a long time.

Assemble the chaise lounge frame with glue and screws and fix the legs. Fasten the base parts to the frame with small nails. In parallel, make the back panel.

Inside the hole for the back on the sides, screw two support rails on which the back rests when folded and on which sections of the rail (teeth) are attached to adjust the inclination of the back. Fix your teeth.

Connect the back to the frame using a pair of one-piece metal hinges. Also make a U-shaped piece for the back and secure it in place with the smaller loops. Check backrest adjustment.

Step Four: Wood Protection

Any furniture sooner or later is subject to wet cleaning. Untreated wood hardly tolerates such processing, and the result often turns out to be zero. Therefore, the tree must be treated with suitable paints and varnishes.

The author decided to leave the wood unpainted so that it could be seen that it was made from natural wood. In this case, the most reasonable option would be to varnish the deck chair with a matte or semi-gloss transparent varnish.

Since furniture is usually used very intensively, you should choose a varnish that will give the most durable and wear-resistant coating. For example, profile furniture varnish. Apply it to the surface of the wood in several layers and let each one dry thoroughly.

Camping in nature is a great way to unwind. Some go to the village, others go to the country, where comfortable sun loungers are waiting for them, allowing them to forget about environment and take a nap. Such attributes relieve tension from the spine and almost all muscles, you just have to choose the most comfortable option for yourself: a rocking chair, a regular folding chair or a sunbed.

Easiest to buy now ready chaise longue, choosing it for the interior of the cottage or for your individual needs. But not everyone has the financial means to do so. A model made by oneself is more appreciated and fully corresponds to the taste of its owner.

Kinds

Creating homemade deck chairs is not difficult. Before starting work, you need to choose the type of this furniture that you want to bring to life. There are several of them:

- Armchair. As a basis, you can take elements from a crib or folding bed. Armrests are custom made.

- Sunbed. The creation process takes about four hours. The product can be made of plastic or wood, which is ideally sanded and varnished.

- Rocking chair. Its back is at an angle, so it is possible to lie down, relax, take a nap. At the same time, it is important to make the bottom of the attribute strong so that it does not loosen when swinging.

In addition to the distribution of products according to appearance, there are variations of construction types:

- Monolithic. When it is created, all elements are fastened together, so disassembly is impossible. Such a deck chair is strong and durable, but the back is not adjustable here and the product as a whole does not add up. As a result, transportation problems may arise.

- Portable. Reliable and compact folding attribute has a special mechanism that allows you to easily adjust its position.

- Soldered with inserts. A practical product will decorate any interior due to its attractive appearance. But inserts from other materials do not guarantee durability.

If the chaise lounge is made of durable materials, it can be supplemented with a blanket, pillows and other items for a comfortable stay.

Possible materials

When choosing a deck chair material, you need to consider its location. It can be a summer cottage, a beach, a special place by the pool, or even at home. There are the following options:

- Wooden. This design is durable, comfortable, environmentally friendly, different in shape and appearance. The only drawback is a lot of weight. To facilitate the transfer of the deck chair, wheels are attached to the legs.

- Plastic. Products are lightweight, inexpensive, easy to care for. Of the negative sides - fragility.

- Fabric. Attributes are convenient and compact. The frame can be made of boards, metal, profile pipes.

- From rattan. Against the backdrop of nature, these sun loungers look incomparable. They are environmentally friendly but expensive. If you have skills in weaving, making such an attribute for relaxation is easy.

- From PVC. The same lounger with a fabric base, however, the basis of the frame is PVC pipes.

Making a deck chair yourself is not difficult, you need to correctly determine the dimensions of all the elements and spend several hours assembling them.

Scheme of manufacturing various options

Before you start making an attribute for relaxation, you need to draw a diagram of it. She plays important role, because it determines the dimensions of the elements for the product, their shape, quantity and other details. You can make such a scheme yourself, but not everyone can do it. Therefore, we give an example of such a scheme. A high-quality deck chair (fabric) will turn out according to such a drawing with dimensions.

It remains only to find materials to create a sunbed. There are also other drawing options different types sun loungers.

From a wooden lattice

Such a deck chair is quite durable, reliable, and its back can be adjusted. For such a model, one should take wood slabs from conifers because they are resistant to climate change. Here is a diagram with the indicated dimensions:

All work is carried out in stages:

- A frame is created from the bars, it is fastened with the help of metal corners.

- Boards are attached to the outside, and legs are attached to them.

- The plate is sawn with a jigsaw and a wooden grate is made.

- The adjustable backrest is separated from the main part of the attribute and fastened to it with a door hinge.

- A fastening bar is attached in the area of \u200b\u200bthe headboard, and a stand is attached to it with screws.

- The finished product is polished and varnished.

If in the future the sunbed will often move from one place to another, it is better to attach wheels to its legs, because the weight of the attribute itself will be considerable.

Fabric on the frame

The work on the frame occurs in this order:

- Ready base is taken from a folding bed or baby cot. In the absence of such, slats are taken desired length or cut and grind.

- Holes are drilled in the main frame, the other is supplied with cutouts (4 pieces) for adjusting the backrest.

- Holes are made at both ends of the rails to install the seat.

- Round crossbars lubricated with glue and installed in the holes.

Now you should prepare the seat itself. To do this, you need to fold the base of the product and measure the length of the canvas. It should sag to comfortably accommodate the wearer. On sewing machine all edges are processed. Then the transverse round bar is wrapped with a cloth and nailed on both sides with small carnations. The attribute is ready and you can enjoy your vacation.

from pallets

This is the easiest way to create a sunbed. Such a product is light in weight (it is easy to move it to different places) and practical (you can put a mattress on it for more comfort). The work takes place in the following order:

- Pallets are dismantled, all nails are pulled out.

- A frame is made from two even boards. They are placed edgewise and parallel to each other, and the rest are sawn in half and attached to the base. The result is a seat with two support legs behind.

- To create the front legs, a board from a pallet is sawn into two equal parts.. Then, with the help of bolts, they are screwed to the seat base and tightened with nuts through washers. The cross bar is necessary to strengthen the legs.

- The back is made from two boards, which are connected to the seat frame with bolts, nuts, washers. This should be done under equal angle. After that on support boards screws are attached to the boards for the back. Behind it, a bar is attached to the rear legs - this is necessary for the strength of the structure.

The final step is grinding the attribute with an emery sheet.

To prevent rotting of the boards, the product is varnished.

From polypropylene pipes

The drawing of such a deck chair is identical to the fabric one, only wooden frame here is replaced by polypropylene pipes. To create a product, you need 2-inch pipes, fittings in the form of the letters "g" and "t" 8 and 6 pieces, respectively. The assembly process has several stages:

- First, a vertical bar is made. A t-shaped connector is taken and pipes of 30 and 45 cm are fastened with it. L-shaped fittings are put on the ends. The lower vertical is also fastened and the two sides are connected.

- An important point: the horizontal bar must be solid and have a length of 66 cm. O on is mounted closer to the connection with the letter "t", which must be directed to the inside of the structure. The other side is two 30 cm pipes, fastened with a T-fitting. This tee must be rotated from the oblong side by 45 degrees. The end result is a rectangle.

- For a rotating seat, a 5 cm pipe is inserted into the triple connecting element, which is fixed with the same part. This will be the base of the horizontal frame.

- The long sides of the horizontal frame are made in the same way as the vertical ones. For the cross bars, a tube 30 cm long is taken and another, consisting of 2 x 20 cm with a tee fitting. The result is a rectangular figure in the same figure.

- The seat will be between the short section horizontal section and oblong vertical. After adjusting the level of inclination, a support is inserted at the back.

The frame is ready, which means that now you need fabric base. To do this, take a dense canvas and fix it on the base.

"Kentucky"

Such an attribute for recreation has a number of advantages: compact, convenient, easy to fold, light in weight, durable and reliable, takes up little space when folded. It looks like a chair high back. Unusual way assembly looks original. To do this, you will need bars, galvanized wire (diameter 4 mm) and the same brackets for fixing the wire (16 pieces), wire cutters, a hammer. The process goes like this:

- A protective coating is applied to the bars. But the parts must be ready for assembly.

- Holes are made. However, they should be larger than the wire by a couple of millimeters.

- The bars are going interesting way, because of which the whole design looks creative. Here is the diagram:

At the end of the whole process, the chair gently rises and unfolds. This folding product looks stylish and modern.

original ideas

People with creative thinking do not always want to see on their territory simple sun loungers, so there are several original ideas creation of models for recreation.

From birch chocks

This design has unusual view so you have to work hard. For such a lounger, birch logs with a diameter of 75-120 mm are needed. But one must take into account what larger diameter chock, the more the finished product will weigh. Before starting work, stock up on the following tools:

- electric saw;

- drill;

- set of drills;

- self-tapping screws;

- staples.

Equipping a place to relax near a private house, it is impossible to do without a sunbed. Here you will need the ability to make a comfortable deck chair with your own hands. It is a folding chair-lounger, on which you can sit in a reclining position.

Chaise lounges are metal, plastic, wooden. Often these materials are combined with inserts made of strong textiles, or they are complemented by light overlays in the form of pillows and mattresses.

Having decided to make a chaise lounge for a summer residence with your own hands, choose wood as the material of manufacture. She is easy to work with. Fully wooden sunbed it will turn out reliable, strong, will serve you for a long time. Detailed description how you can make a sunbed with your own hands, diagrams, design drawings and photos will help to avoid problems in work.

Lounge chair for relaxing in the garden or by the pool

On such a deck chair for giving, it is convenient to sit in the shade of plants reading a book or take a place in a sunny meadow for a beautiful summer tan. Despite the fact that it is a very simple design, the lounger can be installed in three positions: completely horizontal or with two options for raising the back. Moreover, one of the most simple designs. But it is known what easier mechanism the less prone to breakage.

Even an inexperienced master can make such a deck chair with his own hands. It will have convenient parameters even for an adult tall person: width - 60 cm, length - 215 cm.

Materials and tools

The material from which we will make a lounge chair will be a pine beam and a board. Their dimensions, along with a list of tools and fixtures, are listed below:

- 3 bars 4000x100x50 mm;

- 4 boards 4000x80x25 mm;

- 2 studs for attaching the back to the frame;

- drill with drills;

- self-tapping screws;

- sandpaper;

- putty for wood;

- paint (color of your choice);

- carpentry glue to strengthen fixed joints;

- roulette;

- square;

- marker;

- saw or power saw.

Description of work

Before starting work, carefully consider similar drawings in order to understand the logic of subsequent actions.

- First of all, we assemble a frame from a bar. We take 2 parts of 2150 mm and the same amount of 500. We make connections with a drill for self-tapping screws. To increase reliability, we pre-lubricate the places to be joined with glue.

- Let's start working with the fixed part of the surface. We cut a board with dimensions of 4000x80x25 mm with a saw into segments of 60 cm. In total, 13 such parts need to be made.

- Leaving between the boards (60 cm long) gaps of a centimeter, we fasten them with self-tapping screws to the frame. We control the angle of connection of the strips at 90 degrees.

- We proceed to install the legs of the deck chair. For greater stability, the legs in the seat area must be made double. For them, we take 4 bars 35 cm long. We glue them in pairs, then fasten them to the base with glue and self-tapping screws. Any surplus adhesive should be wiped off immediately. This will help in the future to avoid problems with the processing of these areas of wood.

- From the side of the headboard, we also fasten single bars-legs 35 cm long. Then we attach the second bars to them, which are 20 cm shorter than the first ones. We fasten them so that the lower edge of the parts coincides (as shown in the figure).

- Let's start creating the back of the deck chair. We will assemble the frame of this part from a pine beam measuring 100x50 mm. Prepare for the back frame 2 pieces of 880 mm and 3 pieces of 390.

The dimensions of the base of the back are chosen so that it can fit inside the main part of the deck chair (with small gaps for free movement).

- Back upholstery. If you want to give the product a more attractive look, fasten the trim strips along the length of the frame. At the same time, round the top edge of each board on both sides. Keep a distance of 10 mm between the strips.

- To fix the back on the frame for its free movement, you need to prepare holes. Measure 70-80mm from the edge of the last seat board. At the indicated distance, make holes with a drill that pass through the frame of the backrest and deck chair. Place a hairpin on each side of them.

- The mechanism for lifting and fixing the moving part is based on placing bars in special recesses that will not allow the back to fall down. The first selections must be made on both sides of the main frame of the deck chair, stepping back 7-8 cm from the hairpin. The dimensions of the recess should be 10 cm wide, 5 cm deep. We make the second recesses at a distance of 20 cm from the first, 5 cm deep and 5 cm wide.

If you place the first support bar 60 cm long horizontally in the first recess, the back of the chaise longue will lock into the "chair" position. The person sitting on the chair will be comfortable to sit. To change the level of raising the backrest, the first bar should be moved to shortened legs, and the second support bar (60 cm) should be inserted vertically into the second recess. You can fully expand the deck chair by removing the second bar and lowering the back. In this case, the small frame will become on the first bar placed on the shortened component parts legs.

- Finally, take care of finishing the deck chair. Treat the bumps with putty and hide the screws. After drying with sandpaper, sand the corners, surfaces so that there are no sharp parts, burrs and roughness. Cover wooden product stain, this will protect the material from harmful influences. Paint your chaise lounge chair the color of your choice.

The garden chaise longue for giving is ready. You can equip them with a picturesque corner of the backyard and enjoy a pleasant stay.

Compact chaise longue: comfort wherever you want

A folding deck chair, of course, cannot be called a sunbed, it looks more like an armchair. But the product has a number of other advantages. The design is very simple, so making it yourself is not difficult.

The chaise longue has a small weight, compact, so you can easily move to a new place with it. And if you show diligence in work and care when choosing materials, the product will serve you for a long time. personal plot dachas not one year.

What do you need to make a folding deck chair?

Before you start, prepare:

- For the back frame: 2 parts - 1219x38x19 mm, 1 - 610x38x19, 1 - 648x38x19, 1 - 610x64x19.

- For the seat frame: 2 parts - 1118x38x19 mm, 4 - 603x38x19, one - 565x38x19 mm, one - 565x64x19 mm.

- To support the back: 2 parts - 381x38x19 mm, wooden dowel with a diameter of 12 mm and a length of 648.

- 2 pieces thick fabric by 1372x578 mm.

- 2 wooden dowels with a diameter of 12 mm, length - 559.

- 4 bolts with nuts 50x6 mm.

- 12 washers.

- Screws 50x4 mm.

- Glue.

Work sequence

The joints must be additionally glued. After pressing the parts, immediately remove excess glue.

- Consider in detail the drawings, diagrams with the dimensions of the deck chair. They will help to understand the principle of its folding.

- Drill pilot holes, then countersink them for screws.

- Assemble the frame for the back of the sun lounger. Attach the bottom bar 50 mm from the bottom edge. Between the 610x64x19 mm bar and the top piece, leave a distance of 10 mm to secure the fabric.

- Assemble the top of the seat frame in the same way as the backrest. Attach the first bottom plank 203 mm from the bottom edge of the side plank. We fasten the next 3 boards with a gap of 13 mm from the previous one.

- We connect the seat and back frames by tightening them with bolts and placing washers under the bolt heads. We also place washers between the racks of the frames.

- We fasten the support strips for the back with bolts with washers.

- We place the round dowel on the glue in the drilled hole of the planks without gaps.

- It's time to make a seat out of fabric. Putting 2 pieces of fabric together front sides inside, stitch, stepping back 60 mm from the edge. On the one hand, we leave a segment of about 100 mm unsewn.

- We turn the workpiece inside out and sew the sides along the length.

- We lay cavities (for wooden dowels) across the width on both sides, stitch them.

- We thread the dowels into long holes in the fabric.

- After finishing work with wooden base(grinding, coating with a protective agent, painting) put the seat in place.

Folding chaise longue for your dacha is ready. Drawings, images helped to create a practical, comfortable, lightweight chair for outdoor recreation.

Probably everyone who has his own dacha or a private house, you want to relax in your yard in the summer or spring. This will help country chaise lounge (bed), lying on which you can relax your tired body after gardening work or get a golden tan under the warm sun. The design of the lounger allows you to comfortably sit half-sitting or reclining. Such a deck chair can also be useful as a guest sleeping area, you will only need to cover it with a bed.

The author proposes to make such do-it-yourself bed, the model is simple, does not require special skills in its manufacture.

The lounger will be made of wood, it is durable, hardy and natural. Such a country lounger is quite easy to move. You can store it by simply attaching it to the wall of the house or barn in an upright position.

So let's get ready necessary materials:

- wooden boards 400x2.5 × 8 centimeters - 4 pcs.;

- wooden bars 400x5x10 centimeters - 3 pcs.;

- fixing pins - 2 pcs.;

- putty on wood for sealing seams;

- varnish or paint for processing the sunbed.

For the manufacture of country chaise longue we need this set of tools:

- saw (hacksaw);

- electric jigsaw;

- drill;

- screwdriver or curly screwdriver;

- square, tape measure, marker, sandpaper.

The first step is to make a solid frame sunbed. For such a frame, we cut out four parts from a bar - two long longitudinal ones of 215 centimeters each and two short transverse ones of 50 centimeters each.

Next, we assemble the seat - we cut the board into uniform bars 60 centimeters long, 13 of them will be needed in total. The cut bars are screwed to the frame with self-tapping screws, we leave gaps of 1 centimeter between the segments. All subsequent parts are also fastened with self-tapping screws.

We also make legs for a country chaise longue from bars. Single legs 35 centimeters long are attached to the headboard, double legs are attached to the legs for greater reliability of the product.

After that, we make a frame for the back of the product - we twist the frame from two bars of 88 centimeters and three of 39 centimeters. The frame should enter the main structure of the lounger with small gaps. On the frame for the back we fix the boards perpendicular to the boards of the seat, round the ends for aesthetics with a jigsaw.

We drill at the base of the sunbed through holes at a distance of 9 centimeters from the edge of the seat, we attach the backrest structure to the base of the deck chair. The backrest is fixed to the frame on both sides with studs, it should rise and fall freely.

In the frame of the lounger under the back, on both sides, it is necessary to cut out 2 grooves into which the support bars will be inserted. The back will take two different positions. We cut the first pair of grooves 5x10 cm each 9 centimeters from the stud. We make the second pair of grooves 5x5 centimeters at a distance of 20 centimeters from the first.

Now, in order to change the position of the backrest, you need to use a support beam 60 cm long. The beam is initially inserted horizontally into the first groove. In order to make a reclining position, the beam is removed from there and inserted vertically into the second groove.

How nice after a hard day's work to retire in the garden or sit on the lawn by the pond in order to relax, unwind and enjoy the sounds of nature. And what subject garden furniture most associated with comfortable rest? Yes, garden chair! A comfortable portable elongated chair, in addition to its direct functional value, will act as a spectacular exterior element that emphasizes style. suburban area. There is nothing difficult in making a garden deck chair with your own hands. We have selected for you several options for easy-to-make sun loungers. Among them, it will not be difficult to choose a suitable model, which anyone can build.

Such a deck chair can be safely used instead of a bed: a flat surface, an adjustable backrest. What else do you need for an afternoon break?! The only drawback of this design is that it is very problematic to move around the site yourself.

Chaise lounges of this design are very popular, both among vacationers on the sea coast and among the owners of suburban areas.

But there is a way out! We suggest considering the option of a deck chair equipped with rollers. To make a sun lounger, you need to prepare:

- 18 mm thick laminated spruce boards;

- Wooden bars 45x45 mm (for the frame);

- Boards 25 mm thick for sidewall sheathing;

- Electric jigsaw and screwdriver;

- Drills with a diameter of 40 mm for woodworking;

- 4 fixing corners for beds;

- Countersunk head screws;

- 4 rollers 100 mm high;

- Sanding sheet grit 120-240;

- Varnish or paint for woodworking.

Slabs of the required size can be purchased at a carpentry workshop or at the construction market. When choosing plates, it is better to give preference to coniferous products, since they are more resistant to precipitation.

The size of the deck chair depends on the desire of its owner. In most cases, the design is made in the size of 60x190 cm. Having decided on the dimensions of the deck chair, we make two long and two short sidewalls from wooden bars. From them we assemble the frame of the structure, fixing it together with the help of mounting corners. We cover the outer side of the frame with boards.

On long slats at a distance of 5-8 cm from the corner, we fasten the legs of a deck chair, the material for the manufacture of which was bars 5-10 cm long

We fix the legs to the boards using screws 60 mm long.

We mount the wheels: we install rollers in the center of the short legs of the deck chair, fixing them with screws 30 mm long, equipped with a semicircular head with a diameter of 4 mm

To make a wooden grate, using an electric jigsaw, we cut boards 60x8 cm in size from plates.

We attach the planks to the lounger on self-tapping screws, leaving a gap of 1-2 cm. To maintain the gap, it is most convenient to use special spacers

When planning to make a deck chair with an adjustable back, the lattice should be divided into two parts: a sunbed and a headboard. We put both parts on connecting boards and fasten them together with a door hinge.

To equip the mounting plate between the long bars of the deck chair frame, we fix the transverse rail. On the mounting plate we fix the support post, fixing it on both sides with screws

The finished deck chair remains only to be processed by walking grinder, and open with varnish or paint.

We invite you to watch a video that shows how such a deck chair model is assembled:

Option # 2 - fabric chaise lounge on the frame

Another no less popular model of a deck chair that can be folded, giving an almost flat shape.

It is convenient to move a light chair around the site, choosing open sunny glades for relaxation, or, on the contrary, shaded and hidden corners in the garden from prying eyes

To make a folding deck chair, you need to prepare:

- Rectangular slats 25x60 mm thick (2 parts 120 cm long, two 110 cm each and two 62 cm each);

- Reiki of circular cross section with a diameter of 2 cm (one piece 65 cm long, two - 60 cm each, two - 50 cm each);

- A piece of durable fabric measuring 200x50 cm;

- Nuts and furniture bolts D8 mm;

- Fine-grained sandpaper and a round file;

- PVA glue.

Reiki is best made from hardwood species, which include birch, beech or oak. For the manufacture of a deck chair, it is better to use fabrics that are characterized by increased strength and resistance to abrasion. For example: canvas, tarpaulin, jeans, mattress teak, camouflage.

We cut the slats of the required length. By using sandpaper carefully sand the surface.

According to the scheme, where A and B denote the main frames, C represents the stop-regulator, we assemble the main structural elements

In the long rails of the main frames at a distance of 40 and 70 cm from the corners of the structure, we drill holes with a diameter of 8 mm, and then grind them with a round file.

To make it possible to change the position of the backrest in the deck chair, we make 3-4 cutouts in frame B at a distance of 7-10 cm. To equip the seat, we drill holes with a diameter of 2 cm, stepping back from the two ends of the rails. We install crossbars in the holes - round slats, the ends of which were previously lubricated with PVA glue.

Let's start assembling the deck chair: we connect parts A and B with the help of screws inserted through the upper holes. By the same principle, we connect parts A and B, only through the lower holes

The frame is assembled. It remains only to cut and sew the seat. The length of the cut is determined by the possibility of folding. Too short a cut will not allow the deck chair to fold, and an excessively long one will sag in the disassembled position. To determine the optimal length, you need to fold the deck chair and measure the fabric: it should be slightly stretched, but without effort.

We nail a piece of fabric with processed edges to round slats located on parts A and B. To do this, wrap the crossbars with the edge of the cut, and then fix them with small carnations with thick caps. A variant is possible in which “loops” are made at the edges of the cut and put on the crossbars.

Option #3 - Kentucky Folding Chair

The original chair is assembled entirely from bars. If necessary, the chair can always be folded and put away for storage.

The advantage of such garden chair in that, when disassembled, it does not take up much space, while the design is designed in such a way that it allows you to completely relax your muscles

To make a chair, we need:

- Wooden bars measuring 45x30 mm;

- Galvanized wire D 4 mm;

- 16 pieces of galvanized wire clamps;

- Fine-grained sandpaper;

- Hammer and cutters.

For the manufacture of a chair, bars of 50x33 mm in size are also quite suitable, which can be obtained by sawing a 50x100 mm board into three equal parts. The total length of the bars should be 13 meters.

Instead of galvanized wire and staples, galvanized studs can be used, the edges of which are fixed with eight nuts and washers.

To determine the required number and length of wooden bars, it is convenient to use the pivot table. According to the drawing, we make through holes

The diameter of the holes should be 1.5-2 mm larger than the thickness of the wire used. Having prepared required amount bars, all faces should be carefully processed, sanding the surface with fine-grained sandpaper.

Let's start building the structure.

For clarity, we use the assembly diagram of the seat with dividers, as well as the back of the chair. The dotted lines indicate the places of through holes with a wire threaded through them.

On flat surface according to the scheme, we lay out the bars for arranging the seat. Passing wire through through holes

By the same principle, we assemble seats with dividers, connecting wooden bars pieces of galvanized wire

The main structural elements are assembled. We take the ends of the wire, holding the sides of the structure, and carefully raise the chair.

It remains only to cut off the excess wire with wire cutters, and then bend and secure the ends with galvanized staples

Chaise lounge for a summer residence: 8 do-it-yourself models

The garden chair is ready. If desired, it can be coated with a semi-matt varnish for woodworking. This will significantly extend the life of such a popular element of garden furniture.