Installation of a drainage system is relevant even for small baths.

The reasons for this are very logical and simple:

- If there are no drainage gutters, then during rainfall moisture freely flows from the roof directly onto the walls of the bathhouse. Along with rainwater, accumulated dust, dirt, and small debris also flows away. As a result: dirty walls, windows and Entrance door. In such conditions it deteriorates quickly appearance and the service life of wood, plaster, brick and any other materials is reduced;

- Moisture flowing from the roof collects directly near the foundation or blind area, if there is one. And the more often it rains, the more the soil becomes saturated with water. As a result, subsidence of the blind area and even the foundation may occur. In addition, if the foundation is not well-waterproofed, moisture will seep into the subfloor, having a negative impact on the floors of the first floor and the indoor microclimate.

On a note! SNiP 31-06 of 2009 regulates the issues of drainage from the roof. Thus, according to regulations, in private construction it is permissible to have no drainage systems on the roofs of one- and two-story buildings, but provided that above entrance group and the balcony has canopies, and the eaves overhang is wider than sixty centimeters.

Any sauna with installed system drainage system looks more aesthetically pleasing and solid, the appearance is complete and solid. And the benefits of installing gutters are tangible.

It is advisable to install hooks and gutters at the stage of building the roof of the bathhouse, but even after completion of construction and exterior finishing It's not too late to start installing drainage systems.

And the first stage of the upcoming work is choosing a drain and calculating the number of elements.

On sale you can find a drainage system for every taste and budget. From the point of view of economy, plastic (polyvinyl chloride or vinyl) gutters come first, and elite copper and zinc-titanium products close the list. Steel and aluminum systems belong to the middle price category. But focusing only on the price tag is not always correct; you should pay attention to the service life of the products and ease of installation. But the noiselessness of gutters can play a role only in one case - if the bathhouse has living quarters or the building is attached to the main house, but usually the noise of rain through the gutters and pipes rarely bothers those visiting the steam room.

Table 1. Types of external drainage systems by material of manufacture

| Material of manufacture | Peculiarities | For which roofs is it recommended? |

|---|---|---|

| Wall thickness up to 3.3 mm. The color palette of plastic gutters is rich, but after several years of use the shade may lose saturation. It is very easy to install a plastic drain on a roof of absolutely any configuration thanks to a large selection of additional and fastening elements. And the light weight of the products and the absence of the need to use special tools is an additional plus for those who want to do the installation themselves. It can last 30 years, but it is better to choose quality products. with a wall thickness of 3.3 mm. | They harmonize well with roofing made of ondulin, slate, and soft bitumen tiles. | |

| Classic gutters with a service life of 60 years or more. They are made from rolled steel up to 0.7 mm thick. They do not burst, do not break, and do not spoil the appearance of the bathhouse. Relevant for regions with predominantly sunny weather and scorching sun. Among the disadvantages: firstly, certain difficulties may arise during the installation process, and secondly, not all rafter systems are designed to support the weight of a metal drain. | Metal galvanized roofing coverings. | |

| Refers to metal gutters. A layer of primer and polymer is applied on top of the steel base. protective covering eg pural, polyester, modified polyester or plastisol. Service life is impressive, but can be shortened if damaged decorative coating(the corrosion process begins actively). All coatings are resistant to sunlight, except polyester, which quickly loses its color saturation. | Corrugated sheeting, metal tiles with polymer coatings. | |

| Wall thickness up to 0.8 mm. Lightweight, durable, reliable. Not subject to corrosion. Wide choose shades. | Any metal roofs. | |

| Made from material 0.7-0.8 mm thick. Are not subject to corrosion, are not afraid of UV radiation and high temperatures. Scratches on the surface may heal on their own. The service life reaches one hundred years. Disadvantages: incompatibility with some metals and high price. | Suitable for elite roofing coverings, such as seam copper, slate, natural ceramic or composite tiles, shingles, titanium-zinc. | |

| Copper gutters have a thickness of no more than 0.6 mm. Elite gutters are valued for their durability (up to 150 years, subject to proper installation). They do not require painting, frequent cleaning or maintenance. Copper gutters are resistant to heat and high humidity. They do not fade or rust. The average price of one three-meter copper gutter is 6 thousand rubles, one three-meter section of pipe costs about the same, and prices for receiving funnels reach 15 thousand rubles. Install an expensive drainage system for a bathhouse on summer cottage unreasonable, another thing is a prestigious bath complex several floors high. | Ceramic tiles, slate tiles, copper roofing sheets or copper shingles. |

Table 2. Dependence of pipe diameter on roof area

Table 3. Dependence of the width of the trays on the number of risers and roof area

| Roof area, sq.m | Number of risers | Gutter width, cm |

|---|---|---|

| Up to 70 | 9 | |

| From 70 to 140 | 13 | |

| Up to 110 | 9 | |

| 110 - 200 | 13 | |

| No more than 140 | 9 | |

| From 140 to 220 | 13 |

Calculation of the number of elements

To calculate the number of elements, you need to schematically draw a sketch of the bathhouse, take measurements of the building, and then put them in the drawing. This will simplify the calculation process as much as possible. Then you can draw a project on the same diagram drainage system indicating the elements.

Table 4. Elements of drains

| Name | Description |

|---|---|

| The total length of the gutters corresponds to the length of the cornice minus the length of the corner elements, if provided. The standard length of 1 gutter is usually 3 meters. | |

| They are calculated by the number of gutter joints. | |

| 2 plugs for each open line of gutters. If the drain is closed around the entire perimeter of the roof, plugs are not needed. | |

| Prevents large debris from accumulating in gutters. The length corresponds to the total length of the gutters. | |

| The quantity depends on the roof configuration and the length of the eaves (L). If L is 12 meters, then the funnel is installed closer to the center of the eaves or two funnels are placed at the corners of the roof. In accordance with SNiP II-26-76, the distance between funnels cannot be more than 26 meters. | |

| According to the number of internal corners of the bath. Typically the length of the corner is 40 cm. | |

| Accordingly, according to the number of external corners. Elements can be 90 and 135 degrees. | |

| The pitch between the brackets depends on the material from which the drain is made. For plastic systems, the pitch is 55-60 cm, metal - 70 cm, copper - 30-60 cm. The smaller the pitch between the hooks, the greater the load the gutters can withstand. The number of hooks is equal to the total length of the cornice divided by the pitch between the hooks. The hooks are attached at a distance of 15 cm from the edge of the cornice. Additional hooks (2 pcs.) are installed on both sides of the gutter connectors. |

|

| The standard length of one pipe is 3 meters. The total length of the riser corresponds to the height of the bathhouse wall. | |

| If necessary, to connect pipes in a riser more than 4 meters high. | |

| If necessary, for each riser. The size of the knees depends on the size of the eaves overhang. | |

| If necessary, connect risers, combine pipes. | |

| By number of risers, subject to availability storm sewer. | |

| If there is a storm drain. | |

| It is installed 15 cm from the ground if there is a drainage collector (well) or 30 cm from the ground if there is no well. | |

| The step between the holders is no more than two meters. The length of the screw and dowel is selected depending on whether the facade is insulated or not. |

Prices for gutters

gutter

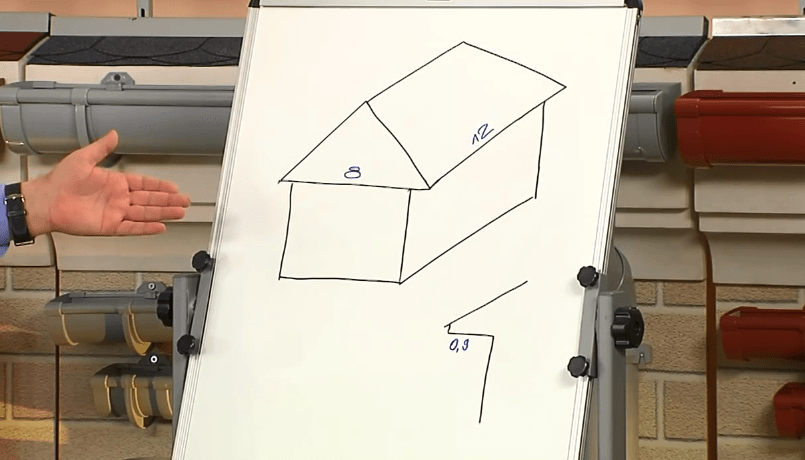

Example of drainage system calculation

Initial data: hipped roof. The length of the eaves on the long side of the bathhouse is 12 m, on the short side - 8 m. The eaves overhang is 0.9 m. The height from the eaves to the ground is 8 m. The roof area is 120 sq. m. m.

The roof area is more than 100 sq.m, so we choose gutters and pipes with a cross-section of 130 mm. The facade is insulated, the insulation thickness is 50 cm. We choose screws 160 mm long. Bend – 67 degree elbow.

Cornice length:

8 + 8 + 12 + 12 = 40 meters.

Number of gutters:

40 m: 3 m = 13.3 pcs.

Round 13.3 to the larger integer 14.

Number of drainpipes:

8 m (length from eaves to ground) x 4 (number of risers) = 32 m.

32 m: 3 m (length of one pipe) = 10.66 (rounded to 11 pieces).

Two more pipes will be needed to bring the drain to the wall.

Total: 13 pipes.

Number of brackets and extensions. The bracket is fastened from the edge of the funnel at a distance of 10 cm, the step between the hooks is taken to be 55 cm. In total, 80 brackets will be needed.

If the hooks are attached to the front board, you will need 80 x 3 = 240 self-tapping screws.

If there is no front board, you will need bracket extensions (straight or twisted).

Straight ones are attached to the flat part of the rafter system.

Twisted extensions are attached to the side of the rafters.

Using the same extensions, if there is no frontal plate, couplings and funnels are attached. In this case, the number of extensions is equal to the number of brackets + number of couplings + number of funnels. A total of 94 extension cords will be needed.

Prices for bracket extensions

bracket extension

Number of double-coupled bends: 8 pieces. There are 2 outlets for each funnel.

4 funnels x 2 outlets = 8 outlets.

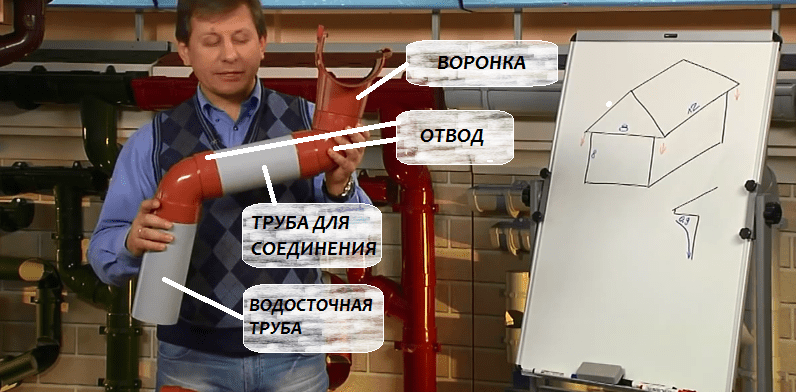

Scheme of connecting a funnel to a drainpipe using two-coupling bends and a pipe section

Number of brackets: 28 pieces. They are installed under each connecting element. The step between the brackets is taken to be 1.5 m.

Result:

- required number of funnels – 4 pieces;

- the same number of outer corners of the gutter;

- number of gutters (L = 3 m) – 14 pieces;

- 10 coupling connectors;

- 80 hooks;

- number of three-meter drainpipes - 14 pieces;

- 8 connectors and 24 pipe brackets;

- screws 160 mm long will need 24 pieces;

- number of bends (67 degrees): double-coupled - 8 pieces, single-coupled - 4 pieces.

Single-socket outlet, fastening diagram

Single sleeve bend 67 degrees

Important! Do not transport three-meter drainage elements on the roof of a personal car, do not store plastic parts under the hot sun, do not place heavy objects on lying gutters or pipes.

Prices for different types of pipe bends

pipe bend

Video - How to choose hooks

Installation procedure for a plastic drainage system

Tools:

- metal hacksaw with fine teeth;

- device for bending metal hooks;

- construction level and tape measure;

- screwdriver, dowels and self-tapping screws for wood;

- file;

- construction cord (rope);

- adjustable pliers;

- marker or pencil.

Basic principles mounting

- The slope of the water intake trays is 3.5 mm per linear meter of length.

- The water flowing from the drip should fall into the central part of the trays.

- The edge of the bracket and gutter should not intersect the line of the roof slope.

- If we conditionally continue the roof slope in a straight line, then the bracket should be 1 cm below this line.

Subject to compliance with the indicated rules, moisture flowing from the roof will not overflow the edges of the trays, and spring period there will be no risk of deformation and breakage of gutters during an avalanche.

Installation procedure

Stage 1. Determine the location of the water intake funnel. It can be located at the edge of the cornice or closer to its middle. But always, regardless of the installation location, the funnel is located at the lowest point of the gutters along the entire eaves, that is, the trays should always be tilted towards the storm drain.

Using a marker or pencil, mark the line where the funnel will be fixed.

Stage 2. Plastic brackets are used to attach the gutters to the frontal board.

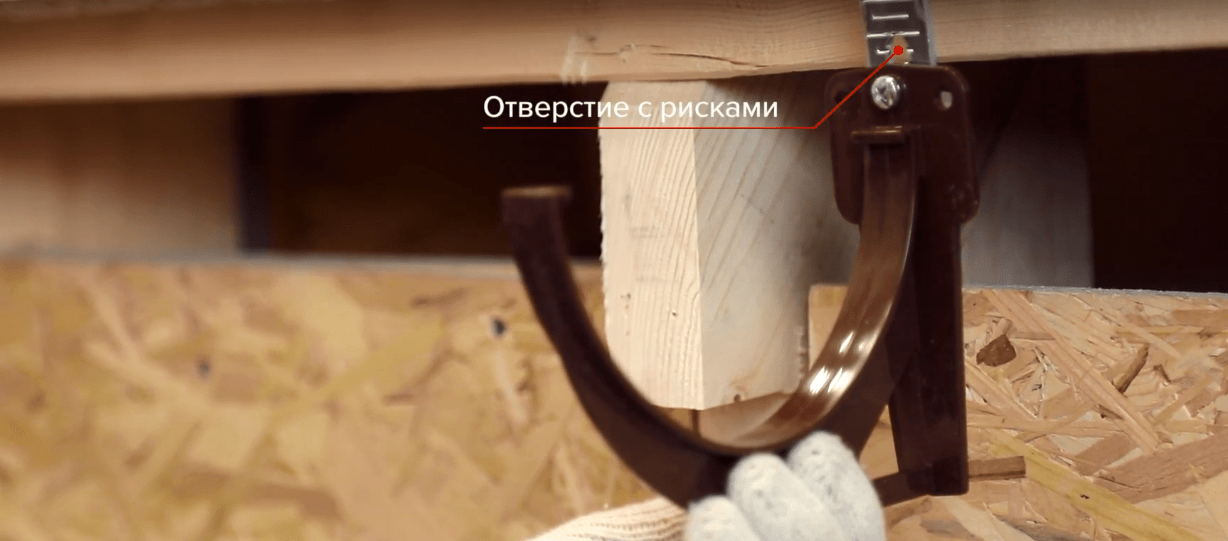

Mark the location where the bracket is attached. The extreme hook is always attached fifteen centimeters from the corner or edge of the roof.

We fix the first bracket, not forgetting the main principle of installation: the hook should be located 1 cm below the continuation of the roof slope.

Important start installation from the outer hooks in order to set the correct slope of the entire drain.

Stage 3. Using a tape measure, we measure the distance between the installed hook and the place where the storm drain will be installed.

Taking into account a slope of 3.5 mm per 1 linear meter, we calculate where the attachment point will be located. For example, if there are 2 meters from the hook to the funnel, then it will be 7 mm lower.

Stage 4. We fasten the storm drain with self-tapping screws to the front board. There are factory holes in the funnel for screwing in hardware.

Important! If there is no frontal plate, the funnel must be fixed using bracket extensions.

Stage 5. We pull a string between the storm drain and the outer bracket.

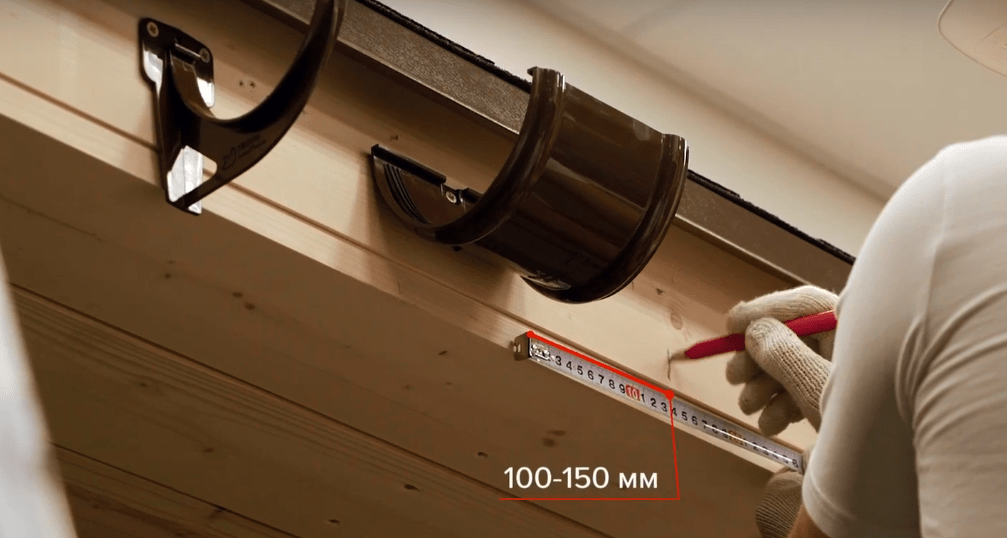

Along the line of the stretched laces we install brackets on both sides of the storm drain. The recommended distance from the edge of the funnel to the bracket is 15 cm.

We attach intermediate hooks in increments of 50-60 cm. If the distance between the brackets is made greater, then the gutters are likely to become deformed.

How to attach brackets if there is no front plate?

Option 1. If the roof is not already covered and the structure does not include a fascia board, either metal hooks or straight bracket extensions that are mounted on top of the rafters are used to install the gutters.

on a note! Most often, the pitch of the rafters does not coincide with the pitch of the hooks. In this case, it is permissible to fix the brackets on top of OSB-3 boards, having previously cut out the recesses.

Option 2. If the roof is already covered, curved side extensions are used to secure the hooks.

The main advantage of extensions is the presence of holes and grooves, which make it easy to set the position of the brackets and adjust the angle of the gutters.

Stage 6. We begin installation of gutters.

The first step of the work is marking. We measure the required length of the gutter with a tape measure, put a mark, then saw off the excess with a hacksaw. We process the edge with a file to remove burrs.

We lay the gutters on top of the brackets.

First, insert the edge of the bracket into the funnel. There are special notches inside the funnel; these are specially applied markings that take into account the linear expansion of the gutter material when heated.

We insert the gutter from the inside out so that it snaps into place inside the funnel. Apply a little pressure on the gutter during installation.

Similarly, we snap the gutter into the brackets.

Stage 7. We install gutter connectors.

The location of the elements is strictly between two brackets, which are mounted at a distance of 10-15 cm from the connectors.

Markings for fixing brackets

We fix the connector to the front board in the same way as funnels, using self-tapping screws through the factory holes.

We place the edges of the gutters inside the connector, focusing on the notches made inside.

On a note! The connectors are equipped with rubber seals for better sealing of the connection.

Stage 8. Installing corner elements. Both on the external and internal corners of the bathhouse, the elements are fixed equally simply. They don’t even need to be screwed to the front board, you just need to snap the edges of the gutters into them.

Stage 9. We install plugs on the gutters.

Note! Depending on the gutter configuration, the plugs can be right-handed, left-handed or universal.

If necessary, we also install a plug on the funnel (in the case when it is located close to the corner of the roof), using a small piece of gutter to connect the elements.

Stage 10. At the final stage, we move on to the installation of drainpipes. We carry out installation from the funnel from top to bottom.

The order of connecting the elements depends on the configuration of the roof and the size of the eaves overhang.

Stage 11. We fix the drainpipes with universal clamps.

Important! There should be no more than one and a half meters between adjacent clamps.

Stage 12. We connect the pipes with couplings, and then secure the structure with a clamp. Each coupling has a special seat for the clamp.

Stage 13. All that remains is to install an elbow to drain the water. This elbow, like other elements, must be secured with a separate clamp.

Test the operation of the entire gutter by pouring a bucket of water onto the roof (but not directly into the gutter!). Make sure that water flows from the roof into the central part of the gutters, enters the funnel and flows through the pipes to the ground or into the storm drain.

This completes the installation. In order for the drainage system to last as long as possible, do not forget to take care of it: inspect the condition of the elements twice a year, clean the trays from large and small debris.

Video - How to install a PVC drain

Any building needs high-quality removal of precipitation. The roof itself is airtight, and storm water and snow escape thanks to the slopes. But if flowing moisture gets onto the façade or foundation of the building, they will become damp and wear out faster. Therefore, every building needs a drain. This is a protective structure consisting of a system of gutters located around the perimeter of the roof and drain pipes.

Why do you need a drain?

An external drain is a set of open gutters that collect moisture from the roof and direct it into vertical outlet pipes. The places where the structure ends are equipped with water collection tanks or storm drains.

The gutter protects the house from the destructive effects of moisture

Gutter functions

The drain performs the following functions:

- Protective. Consists of abduction Wastewater from the walls and basement of the house.

- Decorative. Beautiful homemade drain will decorate your home or gazebo.

- Cumulative. With the help of such a system, stormwater can be used to fill a special tank for irrigation.

Industrial drains are made from special plastic or galvanized steel and their cost is quite high. And if you add plugs, funnels, corners and elbows, the price will double. Ready-made parts have their advantage - they are easy to assemble, like a construction set. To save money, craftsmen found an alternative and began to make their own drainage systems from improvised materials, for example, from plastic sewer pipes. Therefore, if you already have a house or cottage, but there is no drain there, then you can risk making it yourself.

A homemade drain can last for many years

If you approach the matter wisely and choose the right material, then a homemade drain can be used as the main one.

Types of drains

There are such types of drainage:

- External or external. This type is suitable for self-installation.

- Internal, which is included in the project. Most often, this type is installed on flat roofs; pipes made of any material are suitable for it.

Materials for homemade gutters

Previously, only metal was used to assemble drip systems. More often - galvanized or polymer-coated steel, less often - copper or aluminum. Now the range suitable materials increased significantly:

- Gutters made of galvanized steel. They are durable, reliable, resistant to loads and temperature changes. Their disadvantage is noise and susceptibility to corrosion.

Galvanized steel is one of the most popular materials for gutters

- PVC drip systems. They are lightweight and low noise, easy to assemble and withstand temperature changes well.

PVC drain - reliable and silent

- Drainage systems from sewer pipes. Thanks to convenient installation and a wide variety of adapters, such pipes have become an excellent replacement for industrial PVC drains.

Sewer pipes are an excellent material for drainage

- Ceramic pipes and gutters. They will require special clay and pottery skills.

Ceramic pipes are very durable

- Low tides from plastic bottles. Quick to install, but suitable as a temporary alternative.

Bottle plastic is the most available material to create drainage

- Wooden gutters. They are made by hand and last a long time only with special treatment.

Wooden gutters are very decorative

- Copper drains. Suitable for long-term use, but over time they become covered with patina.

Copper gutters look noble and prestigious

For handmade A standard drainage system often uses plastic sewer pipes. They have a number of undoubted advantages:

- affordable price;

- a wide range of pipes and adapters, as well as all kinds of fastening mechanisms;

- light weight, which facilitates transportation and installation;

- possibility of self-cutting;

- durability.

Since such pipes come in different colors, you need to figure out which ones are recommended to be used for arranging a drainage system:

How to make a drain with your own hands

Before purchasing pipes, a diagram of the entire system is drawn up, including all parts of the structure and their quantity:

The cross-section of the pipes is selected based on the area of the roof slope. You can use the following scale:

- slope area up to 50 sq. m - pipe diameter 8 cm;

- up to 125 sq. m - 9 cm;

- more than 125 sq. m - 10 cm.

The remaining elements are purchased based on the diameter of the pipes from which the gutters are made.

As already noted, before purchasing materials and installing a drain, you need to draw detailed diagram, which should indicate:

- roof perimeter;

- length and number of gutters;

- mounting points for brackets, joints and funnels;

- location of drains.

Based on the perimeter of the roof, the pipe footage for future gutters is determined. Since it is sawn in half and two pieces are made from one piece, the required length of the pipes will be equal to half the perimeter of the roof. Next, the number of drainage risers is calculated. To do this, a plan is drawn on which all elements are marked. The distance between them cannot exceed 5 m. After determining the number of gutters, their length is calculated, for which the distance from the eaves overhang to the ground is measured. This will be the estimated height of the drainage riser. This figure is multiplied by the number of parts and it turns out required length pipes. Next in the project are the tees connecting the gutters and risers. If the risers deviate at an angle, ready-made adapters are purchased. A special universal joint sealant is also required.

Tools for work

To work you need:

- wood screws;

- screwdriver;

- grinder, jigsaw;

- hacksaw for metal;

- screwdriver;

- construction cord;

- level and tape measure;

You will also need scaffolding.

Construction of a drainage system

After acquiring the materials, you can begin to manufacture and assemble the drainage structure.

Creating gutters

To make a gutter from the pipe, it should be sawed in half. This can be done with a grinder, choosing a diamond-coated disk with segments. Then the plastic will not melt when cut. Can also be used electric jigsaw. For convenience, you need to construct something like a guide and secure it to the workpiece so that the cut is even. It can be made with a simple hacksaw. The guide can be a ruler attached to the workpiece with tape, or a thread stretched over self-tapping screws screwed into the pipe at both ends. The sections of pipe entering the tee are not sawn. This guarantees reliable connections.

One plastic pipe produces two drainage gutters

Manufacturing and installation of brackets

Brackets are used to secure the gutters. You can buy them or make them yourself from strips sheet metal, bending it to fit the gutter. The bracket is the basic component of an exterior drain that supports the gutter. With the help of hook-shaped holders, the configuration of the water intake circuit is formed.

The brackets can be made independently from a strip of steel with a thickness of at least 2 mm, because they must be reliable. You can purchase ready-made strips for electrical work. Their cross-section is initially suitable; all that remains is to cut the workpieces to length.

Workpiece size:

To ensure that all brackets are the same, you can use a device for bending steel strips or steel pipe the right size as a template. It is also recommended to hammer nails on a thick board in the required sequence and bend the holder using a piece of pipe as a lever.

After giving the shape, holes are drilled in the brackets - two for attaching to the cornice, the next two for attaching the gutter. Finally, the holders are painted with anti-rust paint - it is more durable. The brackets are attached in several ways:

The brackets are mounted taking into account the following principles:

Having chosen the method of fixing the brackets, you can get to work:

- The two outer brackets are attached first, between which the required slope is maintained.

The two outer brackets are attached first

- A cord is stretched between the fixed brackets, and places for attaching all other elements are marked along this straight line.

- The brackets are screwed to the base in increments of 550–600 mm.

A distance of 5–6 cm is maintained between the brackets

- The next thing to install are plastic adapters or funnels for the future drain. One funnel is capable of collecting water from 120 m of roofing.

The hole for installing the funnel is cut using a hacksaw

- Gutters are installed. They gather both on the ground and under the roof. The main thing is to connect the joints correctly. They are attached with glue or joined using special aluminum clips. In case of joining, it is necessary to use a sealant. The mounting height of the brackets depends on the region. If there is little snow in winter, then you can fix it wherever it is convenient. Otherwise, the gutter is lowered so that snow falling from the roof does not take the gutter with it.

Gutters are joined with clips or placed with glue

- When the gutters are assembled and lie on the brackets, adapter pipes from solid pieces of pipe are inserted into tees or drain funnels. Before this, they are treated with sealant. At the top end drain system a plug must be installed.

The plug is installed on the rubber seal

Video: installing curtain rod brackets

Installation of external drainage risers

Assembling downspouts looks the same as joining gutters. If the pipe is lengthened, then an adapter is placed on the sealant between the sections. The process requires compliance with a number of rules:

- the drainpipe should extend 10 cm from the wall;

- for fastening to walls you need to use clamps;

- the pipe should be installed from top to bottom;

- Insert the upper section into the funnel and secure with sealant.

If necessary, the riser pipe can be connected to an adapter for storm drainage. It is recommended to replace it with an elbow, under which a container is placed for draining water.

The installation of the drainpipe must be carried out in accordance with the rules

It is recommended to additionally protect the finished drain from debris by installing rolled construction mesh in the gutters. The diameter of the rolled roll should be slightly smaller than the diameter of the pipe from which the gutters are made. The protection is fixed with plastic clamps.

The drain can be protected with a mesh made of different materials

Video: drainage from sewer pipes

Homemade galvanized steel drain

Creating a drainage system made of galvanized steel requires certain knowledge and skill. Typically, roofing sheet steel 0.5–0.7 mm is used. It should not be less than 270 g per square meter. m.

Tools

You need to prepare:

- metal scissors;

- felt-tip pen for marking;

- hammer and mallet;

- pliers.

Making a pipe from tin

Pipes are a simple element of the drainage system and are very easy to make at home. Galvanized steel sheets or thin tin are suitable for work. The manufacturing method of these materials is the same.

It is easy to make a steel pipe yourself

Step-by-step instruction

The work is performed in the following sequence:

- Calculation of the quantity of materials and their purchase.

The weight of the steel sheet must be at least 270 g per square meter. m

- Laid on flat surface the sheet of metal is cut to the size of the gutters and pipes of the future drainage system. The width of the pipe blank should have a margin of one and a half centimeters for connecting the edges. A rebate line is also applied - on one side at a distance of 0.5 cm, and on the other - 1 cm. Before shaping, the workpiece can be painted to extend its service life.

To make your drainpipe last longer, you can paint it.

- Using pliers, the pattern is bent on the smaller side at an angle, and on the larger side - like the letter G.

- The metal is leveled with a mallet at a right angle. The sides of the workpiece are connected, and the smaller part should fit into the larger one.

- The workpiece can be shaped into a cylindrical or semi-cylindrical shape manually using a template. A sheet of metal is placed on a pipe or log of the required diameter and tapped with a mallet.

You can shape the drainage pipe yourself

Installation of a steel drain

The principles of installing a drainage system made of galvanized metal are similar to installing a drainage system made of plastic pipes. But there are also differences:

- Once the starting point is determined, the gutter brackets are installed.

- Metal gutters are laid with an overlap of 7–10 cm in length. The overlap is designed to compensate for the expansion of the metal in the summer.

- Funnels are installed, which should be located between the brackets. The holes for the funnels are cut with metal scissors.

- The funnels are connected to the pipe at a sufficient distance from the wall.

- The pipes are fixed with clamps.

- The ebb is attached to the bottom of the pipe.

- An anti-icing system is installed.

Video: constructing a metal drain

Drainage from plastic bottles

The cheapest and easiest option is to create a drain from plastic containers. It will be easy to accumulate the required amount of such material, but for the design you will need 1.5-liter straight bottles. In addition to them, you will need wire and brackets.

A drain made of bottle plastic is assembled very quickly and is cheap

Tools and materials for work

It is worth preparing:

- furniture stapler and staples 10–12 mm;

- construction knife;

- drill or screwdriver;

- thin drill;

- wire;

- awl;

- plastic container.

Step-by-step instructions for making castings from plastic bottles

- The first step is to calculate the length of the future drain. For convenience, you can draw a sketch. The functional part of the bottle will be 15–20 cm. This plastic is not suitable for long (more than 5 m) structures.

- Bottles are cleaned of stickers and labels.

- Then the bottom and neck of the plastic container are cut off at the point where the top tapers off. For the gutter, the resulting cylinder is sawn in half.

A plastic bottle needs to be prepared to make a drainage system out of it.

- The gutter is assembled from plastic rectangles using a stapler. The plastic is overlapped (1.5 cm) and secured with two or three staples. The bottoms are used as plugs for rotary structures.

You need to fasten the parts of the bottles for the gutter with a stapler

- The resulting light gutter is attached to the roof. To do this, holes are drilled in slate or other roofing material at a distance of 20–30 cm. Similar holes in the gutter are made with a screwdriver or an ordinary awl. Next, a wire is passed through the holes, which attaches the drain to the roof.

- Drainage can also be easily constructed from bottles. We cut off the neck of one, and from the rest we make the already familiar cylinders. A bottle with a cut off neck will serve as an adapter - you will need to make a hole in it for the edge of the gutter.

The finished structure made from plastic bottles will last about a year

The finished design will last at least a year, but then you will have to take care of creating a more advanced system.

Video: gutter made of plastic bottles

Obviously, creating a drainage system yourself is available to anyone who wants to equip their home with an economical and practical design.

If you do not have knowledge of how to properly attach a gutter, then first study in detail the technology of the process from start to finish. It is ideal, of course, to install a drainage system when building a house. But the completed house should not scare you, because the installation of gutters of the drainage system will only deviate slightly from the basic technology, namely:

1. Installation of fasteners is the beginning of the installation of the entire drainage system, and therefore it is so important to choose the right fasteners, which are brackets.

Now on the construction market you can find sets of gutters with selected fasteners. If such a product is not available, keep in mind that the diameter of the brackets must correspond to the diameter of the gutter.

It is recommended to first calculate the number of these parts based on the material of the drainage elements of the structure. So, for fastening metal elements, it is advisable to maintain a distance between brackets of 0.5-0.6 m, and for plastic gutters, 3 fastenings per 1 m are required. Add here complex external and internal turns, and you will get the required number of fasteners.

2. Now you need to decide on one of the methods for attaching gutters, for example:

- Attaching the gutter to the front board. This method involves the use of plastic drainage elements with a fully completed roof. Selecting metal gutters will require the installation of short special hooks.

Please note that this option is applicable in places where large amounts of snow falling off the roofs are minimal, otherwise the drainage system may collapse.

- The rafter legs are suitable as a basis for attaching the gutter. This option is very reliable on large roofs, but the disadvantage of this method is that it can be used before laying the roof. In addition, the pitch of the rafters should not exceed 60 cm.

- You can attach the gutter to the corrugated sheet, especially since the service life of this roof reaches up to 30 years.

- Attaching the gutter to the eaves is suitable in the case of a metal tile or ondulin roof. Compliance with the rafter spacing of 0.6 m remains relevant here as well.

- The gutter is attached to the wall when there is no front board, rafters, etc. Then metal crutches, specially designed for installing gutters using studs, are driven into the wall.

- Attaching a gutter to sandwich panels is one of the most complex methods of installing a drainage system, and also has a more expensive cost. To attach the gutter to this type of roof, the insulating material must be cut under the top panel skin. Then you need to push the bar through and attach it to the panel below. Hooks are installed on the bar itself, into which the gutters of the drainage system are subsequently inserted.

People with little income are always interested in how to properly install gutters on a slate roof.

In this case, the method of attaching the gutter to the front board will help. At the same time, do not forget to maintain a slope of the gutter of 1 m, following established rules SNIP.

There are more original way, but for this you need to study the instructions on how to properly install gutters made of galvanized steel, especially since to reduce the cost of work you can make gutters yourself from galvanized sheets. All we need to do is cut strips 0.2-0.3 m wide to the required length. Then give it with a hammer U-shape gutters and install them under the slate. It is advisable to try to create a slope of the gutter so that it is 5 mm per linear meter. In drainage areas using the Japanese method, you can install chains through which water will flow without splashing or spilling. And if the chains are also decorated, then the drainage system will be original in all respects.

Problems with a constantly wet foundation and damp building walls are familiar firsthand to many owners of private cottages. The best option The solution to problems of this kind is the installation of a plastic drainage system.

Features and stages of work on installing a plastic drain

Of course, when purchasing and installing a gutter, every owner of a private home “cherishes the hope” of spending money once and not thinking about it again. excess moisture for many years.

In this regard, before purchasing a drainage structure, he must conduct a comparative analysis of drains made from different materials. We will conduct the same analysis by comparing metal and plastic systems:

- almost all varieties plastic drainage systems they are distinguished by a wide variety of designs; they can have a rectangular, round or even shaped shape;

- when hitting plastic pipe(gutter, funnel) masses of water flow down almost silently (unlike a metal gutter);

- galvanized steel gutters, even of the highest quality, are inferior to their plastic counterparts in such an important parameter as the period of trouble-free operation;

- the production of products from high-quality steel costs many times more than the production of plastic structures;

- all discussions about the imaginary fragility of plastic drainage systems have no basis in evidence. Many years of experience in their use is a serious confirmation of the durability and reliability of plastic systems;

- Due to the low weight of the plastic structure, it is very easy to assemble and install. In addition, with this approach it is possible to reduce the load on the row structural elements building;

- The likelihood of a leak in the version with a plastic drain is very small. This is primarily due to the geometry of the plastic structural elements.

About preparatory work

A well-drafted project for future assembly and installation work - good opportunity reduce real costs. First of all, you need to decide on two the most important moments: the number of drainage pipes and the length of the hanging gutters of the system.

Based on these two parameters, you can calculate the number of other auxiliary elements, requiring installation. We are talking about drainage funnels, clamps and holder brackets, corner bends, plugs for gutters, and so on.

The diameter of gutters and pipes is usually selected based on two indicators - the roof area of the building and the approximate amount of precipitation falling in a given area (see special tables).

The number of necessary auxiliary parts will again depend on the area of the roof and its configuration (how many slopes). If we are dealing with a non-standard or complex roof, we should, among other things, take into account every break and angle. In the case of a very long roof (length), the drainage funnels of the gutters should be located at a distance of no more than 24 meters from each other.

About installation of gutters

There is a general recommendation for installing a gutter - observing an angle of 2 degrees when installing the structure. In order to ensure a smooth drainage system for moisture from the roof, we recommend using a simple and reliable method. We install a pair of outer brackets at pre-calculated intervals, and place the remaining brackets along the rope at intervals of 60 centimeters and attach them to the rafter system or front boards.

The uppermost ends of the gutters should be located three to four centimeters below the edges of the roof slopes. In this case snow mass will enter the drainage system without delay.

The outer edges of the gutters should be located lower than the inner ones, then if water overflows over the edge, it will not fall on the wall surface.

High-quality roof gutters should be installed in such a way that moisture collects in the middle of the gutters. For this purpose, special gaskets are used, which are placed under the bases of the brackets.

Installation of the gutter is carried out in the direction from the roof to the ground. There are two main ways to seal connections. In this case we are talking about permanent adhesive joints and rubber gaskets. Each of these options has its own advantages and disadvantages.

The joining of adjacent elements is made using understatements. Each assembly part must be inserted until it stops. The option with rubber gaskets has a rather serious drawback - they will have to be changed over time (this is inevitable). Self-replacement repairing a failed drainage system part is a rather difficult and time-consuming process.

Standard length of plastic gutters for roof gutters- three or four meters.

It is known that cutting plastic is a very simple job. However, try to keep the number of connections to a minimum. Each of the burrs formed during the work should be removed with a knife or file (thus, the contact of the joints is improved).

If you have a small cottage, and you have made a choice in favor of the adhesive type of connections - the gutter can be assembled on the ground.

An important point: installation of gutters is difficult without outside help.

About the installation of funnels

Water inlet funnels are attached to the gutter or to the wall surface (in the second case, the funnel simultaneously plays the role of an additional support and connecting part of the gutter). In the option of hanging the water collector on the gutter, it is necessary to make a drain hole in the wall of the gutter.

Water collectors are one of the key components of the entire system. If leaves or other debris gets inside the funnel, it can cause the passage to be blocked. The result of this is often the rupture of drainage pipes. In this regard, it would not be superfluous to equip the funnels with “options” for collecting garbage (we are talking about nets and spiders).

About pipe installation

Most often, when installing a drainage pipe to a wall, an elbow with an angle of 35 degrees is used. The use of such an elbow ensures smooth water flow in the future.

The structure is fastened to the wall using two (or more) clamp holders (the interval between clamps is 2 meters). The recommended interval between the drain and the wall surface is 3 centimeters. This figure can be used as a guide when cutting sections of pipes connecting elbows (here it is necessary to take into account the length of the connecting sections inside and the length of the fittings on the outside).

Water jets are attached to the lower ends of the pipes, which are necessary to drain water flows from the walls.

If we are talking about installing a drainage system in a house where people will live on a permanent basis, it is worth investing in a heating cable. A similar "option - good way preventing ice build-up in pipes, catch basins and drain funnels.

Video: Installation of PVC gutters

One of the most important functions of the roof is to protect the attic and attic from precipitation. But, flowing along the roof slopes, the water inevitably transfers to the walls and foundation. The result is rapid destruction load-bearing elements building structures. This action can be avoided by installing roof drainage systems.

System classification

There are two criteria for classifying a drainage system. They directly determine the installation technology. Depending on the manufacturing method, drainage systems can be industrial or homemade. In the latter case, we are talking about an object of handicraft production. What benefit can there be from this system? If a person has the appropriate abilities, a drain can be beautiful and unusual.

Arrangement homemade system does not involve significant costs. Among other things, the user can choose the scheme that suits him. Gutters are usually made of galvanized steel, so constant maintenance is required, and this is the disadvantage of the system. Among the disadvantages is the difficulty of joining individual elements.

Factory modifications meet all standards and necessary parameters. If necessary, you can join different elements supplied by the same manufacturer. Classification according to the material used assumes the presence of plastic and metal models.

Plastic system

There are adhesive and non-adhesive systems. In the first case, installation is carried out using glue . Plastic gutters have the following advantages:

The components are varied, so the drainage system can take on almost any configuration. This makes it indispensable for installation on broken roofs.

Disadvantages of gutters made of polyvinyl chloride:

- The material tends to collapse under the influence of mechanical stress. That is why this kind of system is not installed on high-rise buildings. Plastic system can only be installed on low-rise buildings.

- Unsuitable for repair. Destroyed components cannot be restored.

- Increased linear expansion coefficient.

- The need for periodic replacement of seals, which entails the assembly and disassembly of elements.

The installation is fixed with rubber seals.

Drainage system equipped with metal profile, has several varieties. There are galvanized and copper modifications. There is a galvanized version with a polymer coating. The key difference between them is the duration of operation and cost.

Drainage system equipped with metal profile, has several varieties. There are galvanized and copper modifications. There is a galvanized version with a polymer coating. The key difference between them is the duration of operation and cost.

The positive qualities of metal gutters are strength and reliability, the ability to withstand significant snow loads and other environmental influences. They do not support combustion. Worker temperature regime they vary from -60 to +130 degrees. Among the advantages is dimensional stability.

Metal gutters have the following disadvantages:

- difficulty in installation;

- small selection of colors;

- rust formation if the protective layer is damaged;

- significant weight of the system as a whole;

- a small number of components, due to which installation can only be carried out on roofs with an angle of 90 degrees.

It is difficult to answer which system is more efficient, plastic or metal. It all depends on operating conditions and other factors. Whatever it was, the choice of system should be based on quality, not price.

System installation

The technology for installing drains includes selecting a system, purchasing materials and carrying out appropriate calculations. Depending on bandwidth systems, there are several drainage options. Let's say they can be designated in the form of numbers 100/75, 125/90, 150/110, which indicates the ratio of the diameter of the pipe and the gutter.

The technology for installing drains includes selecting a system, purchasing materials and carrying out appropriate calculations. Depending on bandwidth systems, there are several drainage options. Let's say they can be designated in the form of numbers 100/75, 125/90, 150/110, which indicates the ratio of the diameter of the pipe and the gutter.

Each manufacturer has its own indicators. The configuration is also different. This is why you should not connect systems produced by different companies. A variety of systems is necessary so that each person can choose the modification that suits his needs.

Selection of drainage

For correct selection water drainage systems must be familiar with the maximum precipitation level in a particular region. After this, you need to calculate the area of the slope. This should be done not for all elements, but for the largest one. It is this size that will determine the choice of gutter.

For correct selection water drainage systems must be familiar with the maximum precipitation level in a particular region. After this, you need to calculate the area of the slope. This should be done not for all elements, but for the largest one. It is this size that will determine the choice of gutter.

If the building has flat roof or a roof with a slope of less than 10 degrees, the effective surface area will be E1 = A * C. The result will be in square meters. After choosing a system, you need to determine its type and calculate the amount of materials. For this purpose, prepare drawings or diagrams of planes with dimensions. Thanks to them it will be possible to carry out calculations, and then installation of the drainage system.

Calculation of the drainage system

The important feature here is the gutter. It can be rectangular or semicircular. The purpose is to collect precipitation from the roof. Its length is from 3 to 4 m. It is fixed with brackets, which are fixed in increments of 60 to 90 cm. The drainage gutter must have a slope of at least 1 cm for every 3 m. The number in linear meters is equal to the perimeter of the base. In fact, this is the length of all surfaces on which the gutters of the drainage system will be installed. It is sold individually in 3 and 4 pieces. linear meters.

All obtained dimensions must be rounded to the whole length of the gutter. The smaller the connection, the simpler and installation is cheaper. External and internal corners the gutters are 90 and 135 degrees, respectively. The corner gutter is designed to change the direction of water flow. It is mounted by means of fastening on internal and outside corners roofs. A total of 4 external corners and 2 internal corners are required. They should all have 90 degree angles. If there are acute and obtuse angles, it is necessary to select a system in which these angles are absent.

A variety of angles can be made from a plastic gutter if you cut out part of the product and connect the halves at the right angle. The parts must be connected using glue, that is, by cold welding.

Gutter components

There can be from 5 to 17 connecting elements. It all depends on the installation features of a particular system. In most systems, the corners are fastened directly. But there are some examples where a connector is used for this. If the installation is carried out with glue, compensation and conventional connectors must be used. The first type is installed when the roof length is more than 8 linear meters. It can be installed without the use of glue. A connector is required to accommodate the linear expansion of the crack during cooling and heating.

There can be from 5 to 17 connecting elements. It all depends on the installation features of a particular system. In most systems, the corners are fastened directly. But there are some examples where a connector is used for this. If the installation is carried out with glue, compensation and conventional connectors must be used. The first type is installed when the roof length is more than 8 linear meters. It can be installed without the use of glue. A connector is required to accommodate the linear expansion of the crack during cooling and heating.

Fastening hooks

These components are short and long. The latter are necessary for hanging the gutter on the rafters and are secured before installing the roofing material. The first ones are short and are used to fix the gutter on the front board. Accordingly, it is possible to install the components on a finished roof covered with roofing material. The fastening hook is installed at intervals of 60 cm. An obligatory step is the installation of funnels and plugs at the joints and near the corners.

Vertical drainage requires a drainpipe. They can have a round or rectangular cross-section. Designed for vertical liquid drainage. The bracket is necessary for attaching the pipe to the wall. According to the method of fixation, a distinction is made between the stone method, when the element is fixed on a concrete, stone or brick base, as well as installation using hardware. The third method involves fixing to wooden walls using self-tapping screws.

Depending on quantity funnels determine the number of pipes. If, say, there are 4 of them, then 4 places will also be required to install the pipes. In linear meters, their length corresponds to the total length of all walls along which installation is carried out. Pipes are sold in lengths of 3 and 4 linear meters. Rounding up is possible since joints on the pipe are undesirable. That is, if your house has a height of 3.5 m, then you need to buy a pipe 4 m long. Half a meter from here will be spent on waste and other needs. Pipe fasteners are installed every meter. Their installation near the knee is mandatory.

Plastic drainage system

To install a polyvinyl chloride system, it is necessary to install drainage funnels on the roof. There are stormwater, water intake and roofing systems. This is followed by the installation of brackets. The gutter fasteners, which are located as close as possible to the funnel, are installed at a distance of 2 cm from it. They serve as a holder. The angle of inclination relative to the funnel is 2 degrees or 4 mm per 1 m. It is very convenient to check the inclination with a nylon thread. If the wall has a length of 10 to 20 m, it makes sense to install the gutter in the following ways:

- Simple method. It is also called direct. The funnel is installed at the end of the slope.

- Double slope. It is drawn from the middle of one plane to the middle of another.

In the first case, the middle gutter is located at the highest point. Due to this, water moves to the funnels that are located at the corners of the building. In the second case, the two outer gutters are at the highest point. For this reason, the water moves towards the funnel located in the middle between them. Sometimes the length of the gutter exceeds 22 m. Three funnels and a more powerful system are installed here.

In the first case, the middle gutter is located at the highest point. Due to this, water moves to the funnels that are located at the corners of the building. In the second case, the two outer gutters are at the highest point. For this reason, the water moves towards the funnel located in the middle between them. Sometimes the length of the gutter exceeds 22 m. Three funnels and a more powerful system are installed here.

At the next stage, they are mounted gutter connectors of regular and compensation type, if necessary. The connectors are installed between the brackets at the same distance from them.

- The gutter is placed on brackets that are adjacent to the funnel, taking into account the linear expansion of the plastic.

- It is necessary to drill holes for the funnel in right place. To do this, use a special drill attachment - a crown.

Some manufacturers mark the funnel so that installation can be simplified. That is, the temperature scale is indicated on the side. By comparing it with the temperature outside, the gutter can be installed at the desired level.

Some manufacturers mark the funnel so that installation can be simplified. That is, the temperature scale is indicated on the side. By comparing it with the temperature outside, the gutter can be installed at the desired level.

The funnel is an element that does not require glue during installation. If this is provided, a sealing rubber is placed at the point where it adjoins the gutter.

The next step is the installation of the gutter connection. When laying it, the connector must be smeared with glue or the joint must be sealed with an elastic band. No adhesive is required to install the expansion connector. To ensure that water flows in the correct direction, at the end drain pipe It’s better to arrange a so-called teardrop. The installation of corners and plugs for the gutter is carried out using a similar scheme.

Installation of the corner and plugs is carried out using glue and sealing rubber bands. Clamps and downpipes are secured in the next step. Holes for fastening the clamp are drilled at the design state. The installation of the pipe is preceded by installing the elbow or pipe into the funnel. The use of a rubber seal or glue is mandatory. But they are not required for downspouts.

The pipes are secured using a clamp installed in holes drilled in advance. After this, a plastic molding is installed. It must be installed so that water does not destroy the foundation of the house. You can make it conduct water into the channel drainage system or in the appropriate well.