A door closer is a device whose action is aimed at quietly closing the door. The mechanism functions like this: it is applied to the door physical strength, this creates an impulse that is transmitted to the device and acts so that the door opens and closes without sudden movements and noise. If you want to create a door closer with your own hands, you will need parts whose purpose is not related to the principle of operation of the door.

This is what a door closer looks like

Door closers are different. All differ in different dimensions and colors, as well as the design of the mechanism.

Depending on the place of application, the installation for doors is:

- furniture - closers are used in compartment doors in the closet, pull-out furniture elements, in the kitchen, and so on;

- door closer – fixed on main doors, interior doors, as well as compartment doors in storage rooms and dressing rooms.

Existing door closer options

Furniture door closer options are built into the structure during its creation. But you can install door closers yourself by creating the device yourself.

Configuration of closers by device:

- device with drive and teeth;

- camshaft application.

Door closers are installed at the top, bottom, and also mounted in door elements.

Upper door closer

This type species mechanism. There are options for installing door closers at the top:

The door closer installation is selected based on the door opening functions.

If the doors open when a person enters, then the door closer is installed using the first method, otherwise method 2 is applicable.

There is another option for installing the mechanism; it is applicable when the doors open in all directions.

Example of a door closer for a door opening in both directions

Parallel installation is carried out as follows: the mechanism is mounted on the door, the lever is mounted on the base of the door frame using a special plate.

Read also

Adjusting a metal-plastic door

Bottom closer

This door mechanism is used if there is no door frame. That is, if there are hinges on the doors, the lower mechanism is not used, since the closer in this case plays the role of a hinge.

The lower closer is installed in a hole in the floor, which should be made in advance for these purposes.

Bottom closer design option

This mechanism has an upper part that is installed in the ceiling. Without this component, the bottom closer will work for a short period of time.

Hidden door closers

The mechanisms are completely hidden in the door leaf. There are 2 types:

Choosing the right door closer

Before choosing a door mechanism, you need to familiarize yourself with its functions. Principle of operation door closer consists of a quiet, smooth closing of the door. This is reflected in the following factors:

- Saving heat in the room.

- There is no noise when the door moves.

- Noise insulation. When the door fits tightly to the frame, there are no extraneous sounds from the street or another room.

Working principle of a door closer

For proper and long-term operation of the door mechanism, you need to make the right choice of closer.

For the correct functioning of the door closer, as well as its long-term operation for its intended purpose, there are several rules, guided by which you can avoid mistakes when producing the mechanism or purchasing it.

Door closer operation diagram

Depending on the appearance, functioning, as well as type - door closers have different pricing policies.

Do-it-yourself door closer installation

The door closer can be manufactured and installed, adjusted from different means. How to install the overhead door closer?

Detailed instructions for installing a door closer

Step-by-step instruction

If the kit does not contain a model, then the technical data sheet contains the exact dimensions and measurements according to which the door closer can be mounted.

Adjusting the door closer

After installing the door closer, a check is required. If the door opens hard, closes or slams, you can adjust the door closer with your own hands.

There are 2 screws on the closer device. They take on the main functions of the mechanism. 1 screw – speed when closing the door, 2 – adjusting the tightness of closing the door and its fit to the frame. If the door slams, the second screw needs to be adjusted. You need to turn it slowly (a little - half a turn), then check that the door is closed. This must be done until the door stops slamming.

Door closer adjustment options

To close the door a little slower, you need to turn the screw clockwise, so that the speed is counterclockwise.

Closer with more than 2 screws

There are door closers with adjustment screws of more than 2 pieces. In this case, the technical passport indicates the purpose of each screw. In addition to the standard door adjustment screws (speed and clap), there are also screws responsible for other functions of the mechanism.

One screw serves as a door brake when opening. That is, you won’t be able to open the doors with a sudden movement. The second screw leaves the doors open. That is, if the door is wide open, then it will remain in this position and will not close.

Drawing and diagram for adjusting the door closer

Adjustment of the screws is also carried out slowly and by half a turn.

The closer allows the door to close smoothly and without impact. This increases the service life of both door leaf, and castles. Due to the fact that the closer is constantly subject to heavy loads, to ensure normal and reliable operation of the mechanism, it must be carefully and regularly maintained. It is enough to make the necessary adjustments and the device will work flawlessly for many years. There are several adjustment options; you can do all the settings yourself, you just need to know how to do it correctly.

When do you need to adjust the door closer?

The modern door closer appeared relatively recently. Its task is to ensure smooth closing of the door leaf. Such devices can be installed both on entrance and interior doors in houses and apartments, as well as in offices, shops, entrances, etc. Previously, a spring was used to close the door, but in this case the door slammed shut and an impact occurred, which led to a quick failure of both locks and door leaves.

If earlier springs were used to close the door, now modern devices called closers are used

The presence of a closer on the doors implies that when opening them, it will be necessary to apply a certain force, which is accumulated in the mechanism located inside such a device. When closing the door, the door closer smoothly returns the door to its original position.

Before we begin to describe the process of adjusting closers, you need to briefly familiarize yourself with their types. The following types of mechanisms can be found on sale:

- spring. This is the most simple model, which works by compressing the spring when the door is opened, after which it unclenches and the leaf closes;

The spring closer has a simple design, as it works by compressing the spring

- cam with sliding (slide) rod. Its operation is based on the smooth sliding of a slide rod. This mechanism is usually used for door leaves of light weight, as well as where such indicators as compactness, smooth running and small sizes closer;

The cam closer has a sliding (slide) rod

- closer with gear drive. This is the most common option. Its operation is based on the movement of the door under the action of gears. The gear closer is more durable and can therefore be installed on heavy doors.

The operation of the gear closer is ensured by the gears it contains.

In addition, you need to decide on the types of closers according to the installation method:

- invoices. These are the simplest models that are mounted at the top of the door. They are usually mounted on entrance doors to a house or apartment. It is easy to adjust overhead closers; for this purpose there are special screws on the mechanism body;

The overhead door closer is attached to the top of the door

- floor These models also have simple design, but they are installed on the floor. In houses and apartments, floor models are practically not used. They are mainly installed in offices, shops and other establishments with high traffic;

The floor closer is fixed to the floor

- hidden. Such structures are difficult to install and regulate. This is due to the fact that they are either inside the door or in the floor, making them difficult to reach.

The hidden closer is hidden in the door leaf, frame or floor

In what cases should the door closer be adjusted?

The door closer is operated in intensive mode, therefore, to ensure its normal operation, it is recommended to carry out adjustment work at least twice a year. If the room is heavily occupied, adjustments may need to be made more often.

Since most door closers contain oil inside, adjustments must be made in warm and cold seasons. This is due to the fact that when the temperature changes, the thickness of the oil also changes and the smooth operation of the device will depend on this.

Most door closers contain oil inside; its thickness depends on temperature, so adjustments must be made in warm and cold seasons

It is necessary to constantly monitor the operation of the mechanism. If you are not satisfied with the speed at which the door closes or if it occurs jerkily, or if the door leaf does not attract well, to eliminate such shortcomings it is necessary to adjust the closer.

Is adjustment necessary after installing the device?

Depending on the design of the closer, the location of the adjusting screws will differ. Despite this, the adjustment is carried out according to the same pattern - when the screws are rotated clockwise, the speed and force of the mechanism increase and vice versa.

Since the weight of the door leaf on which the closer is mounted may vary, adjustments must be made immediately after installation. The screws must be turned very smoothly. It is recommended to make no more than ¼ turn, after which you need to check the operation of the closer. If you unscrew the screw more than 2 turns, it may fall out of the socket, and this will lead to oil leakage.

Since the weight of the door may vary, the closer must be adjusted immediately after installation.

Immediately after installing the closer, its performance is checked and if something is not satisfactory, adjustments are made. The speed at which the door leaf will close is changed by rotating the corresponding screw. If you need to adjust the exhaust, use another screw.

Video: how to choose a door closer

Adjusting the door closer

Now that you know the types of closers and have decided which one is installed on a particular door, you can begin adjusting it.

Although there are several types of closers, the principle of adjustment will be almost the same. Regardless of whether an overhead, floor-mounted or hidden mechanism is installed, you must first study the instructions and determine how many adjustments this model has. The simplest mechanisms have only two adjusting screws located on the body of the device: one is responsible for the speed of closing the door, and the second for its closing. After this, the necessary function of such a device is adjusted. The process of adjusting hidden structures will be more difficult, but here you can do it yourself. It is enough to figure out where the adjusting screws are and use them to adjust the necessary parameters of the closer.

To complete the work you will need the following tools:

Before proceeding directly with the adjustment, you need to decide what the following terms mean:

Adjusting the door speed

The first stage of adjusting the door closer is setting the closing speed. It is recommended to install on entrance doors higher speed closing the door so as not to lose heat; for interior walls this indicator depends on the preferences of the owners.

A door closer, depending on its model, can have from 2 to 5 adjusting screws; their purpose should be found in the instructions for the purchased device..

To adjust the door speed:

Adjustment of aftershock

Adjustment of the closing noise can only be carried out after the door closing speed has been adjusted. To adjust this parameter, you need to use the second screw, which is found on all door closer models:

Open position adjustment

If you often need to fix the door in the open position, you need to buy models with an adjustment called hold open. This function is used when it is necessary to bring in or remove large objects from the room:

How to loosen a door closer

If the doors are difficult to open, you need to loosen the door closer. To do this, you need to loosen the adjusting screws a little and ensure that a small force is required to open the door leaf.

To loosen the closer, you need to slightly unscrew the adjusting screws.

Closing delay setting

Sometimes situations arise when it is necessary for the doors to close not immediately, but with some delay. This function is also not available on all models. To understand whether your closer has it, you need to look at the number of adjusting screws. There should be more than two, and the purpose of each of them can be found out by studying the instructions. This function allows you to configure the door closer so that several people can pass through at the same time while the door is open. It is especially relevant in hospitals, shops, and educational institutions.

Setting the door closing delay:

Video: adjusting the closer

During self-adjustment The door closer must adhere to the basic rule: the adjusting screws cannot be unscrewed more than 2 turns. Almost all mechanisms run on oil, and if you unscrew the screws more, it will begin to leak out. Oil is poured into the device under pressure, so you won’t be able to fill the closer yourself and will have to buy a new mechanism.

To ensure maximum service life of the closer, certain requirements must be met:

If you really need to fix the door, but the closer does not know how to do this, some craftsmen disconnect the lever rods and thus turn off the closer completely. For implementation similar method fixation requires some time and effort. To do this, use a screwdriver or wrench to unscrew and pull out the screw connecting the two lever rods. If the need to fix the door leaf arises frequently, it is better to purchase a door closer with the appropriate function.

The door closer is pretty simple mechanism, and if you operate it correctly and make timely adjustments, it will work for a long time and reliably.

Video: features of operating and adjusting the closer in winter

A door closer is a small device designed to smoothly close a door. It not only minimizes the risk of injury to people, but also protects door structure– hinges, fittings – from rapid wear. How to adjust the door closer yourself?

Types and design of door closers

The working element of the closer is a spring enclosed in a container with oil. The devices differ in installation method:

Top overhead;

Built into the frame;

Built into the floor.

The drive of the closer can be crank (lever) or cam (leverless). Simple models are mechanical, more complex ones are powered by electricity.

Operating loads are indicated in the passport and directly depend on the dimensions and weight of the web.

In addition, each model has a range permissible temperatures. The working medium of the closer is oil; its consistency depends on the outside temperature: the colder it is, the higher the viscosity.

The operating parameters are controlled by a valve system - a thermal damper. Its purpose is to compensate for temperature changes by reducing or increasing viscosity.

At the turn of the seasons, adjusting the closer becomes necessary. Otherwise, one fine winter day you will find that your door is “frozen.”

If the blade closes at the wrong speed (too fast or too slow), adjustment is also necessary.

Important: the device will work properly only when correct installation. During installation, you need to ensure that a right angle is maintained between the lever and the door.

Adjustment instructions

Instructions on how to adjust the door closer are included in the kit. If it is not there, then look below. Let's consider the most common design - the overhead overhead door closer.

Video “How to adjust a door closer”:

There are two screws at the end of the device. The first screw regulates movement in the angle range from 15 degrees to 180. The second controls the closing speed: by tightening it, you reduce the speed, by loosening it, you increase it. By manipulating both in turn, you achieve required work. Some recommendations:

To increase the finishing speed, you need to turn the second adjusting screw clockwise, for the opposite effect - counterclockwise.

The spring tension is changed by turning the adjusting nut. With its help, the door closer is adjusted according to the swing angle.

Video “How to adjust a door closer with your own hands”:

You can pause the movement of a door that is open at a right angle (hold-open function). To do this, move the blade 90 degrees and tighten the lock. This option is useful when you need to carry some kind of cargo through an open door.

If the door is open 90 degrees or more, it will stop completely. To set it in motion, you need to pull the handle. If the angle is less than 90, the door will close smoothly as usual.

You can turn the adjusting screws from the zero mark no more than two turns. If you adjust the door closer yourself, you should remember that It is unacceptable to unscrew the screw completely.

When the valves are displaced, oil leakage inevitably occurs and the device becomes inoperable.

Video “How to adjust a door closer”:

To prevent the closers from being subjected to unnecessary loads, you should not put additional force on the closing door or support it with anything.

Features of Dorma and Geze

The German Dorma door closer is designed to operate in the temperature range from -30 to +40. The Dorma door closer is adjusted by two valves.

The force must comply with the European standard EN. The setting depends on the type and dimensions of the door. The force is adjusted by moving the body relative to the hinges or turning the lever.

The Geze closer is adjusted using the hold-open function, which operates in the range from 70 to 150 degrees. In addition to the usual models of this brand, there are devices with smoke protection: in the case there is a switch with an electronic unit that is triggered by smoke.

This is a simple way to adjust the door yourself. The main thing is not to overdo it and service it on time.

The closer is a device for returning the door to its original position in automatic operation mode. This device silently and softly closes the open sash. If necessary, it holds the door leaf open. Many doors are equipped with modern, practical devices. At the same time, like any technique, the closer needs maintenance, adjustment and troubleshooting.

Types of mechanisms and their design

To better understand the principle of operation of the mechanism, you need to analyze its basic varieties, this will make it easier to figure out how to properly debug a door closer.

For the most part, two types of this device are practiced:

- cam slide - provides soft sliding, practiced for low-weight canvases;

- gear lever - the most common type of mechanism; the movement of the spring is realized through gears; it can be used even for massive door leaves.

Depending on the method of installation, devices can be divided into three main types:

- Overhead structures (overhead)- these are the most straightforward devices to use; their functions can be adjusted using several screws or valves located on the housing panel. They are mounted at the top of the sash, which is extremely convenient during installation. For input street doors Specialized oil-filled devices are manufactured, adapted for operation in hot or cold climates.

- Floor-standing. Floor-mounted systems are also relatively easy to set up. They have proven themselves excellent in banking institutions, offices, shopping and entertainment complexes and where there are high demands on the appearance of doors. These devices are integrated into the floor and are almost invisible to visitors. Sliding type regulator mechanisms are used and are intended for doors weighing no more than 100 kilograms.

- Hidden devices It is quite problematic to adjust them yourself, since they are tucked inside the door leaf or into the floor, which complicates access to them. The devices are in demand where thorough cosmetic finishing and an ideal main façade are required.

According to the principle of operation of the device, they are as follows:

- hydraulic;

- pneumatic;

- electric.

Fixture structure

To the structure of this device The following parts and mechanisms are included:

- cast aluminum body;

- spring;

- piston;

- adjusting screws (valve);

- gears;

- needle bearing;

- rubber seals;

- fastener

Operating principle of the closer

The basic component of the design is a spring system, which, when the door is opened, is compressed and accumulates the energy required to close the door. The compression process is carried out by transferring the force of the traction device to the spring. Toothed gears and racks move the piston, while oil flows through internal channels into the free part of the housing. During the reverse movement of the door, the spring straightens and ensures soft closing.

In what cases is the procedure necessary?

Adjusting the operation of the door closer is quite simple matter. Setup can be done without any problems with my own hands. It is worth understanding in what situations it may be necessary to adjust the parameters of this mechanism. The first thing to remember is that the duration of uninterrupted operation of any mechanism is directly based on the quality of its maintenance during the entire period of operation. As a result, 1–2 times a year it is necessary to inspect the closer and eliminate minor faults. This is especially important during the transitional change of seasons.

In summer and winter, climate conditions vary enormously. Most of closers are filled with oil, and as you know, any liquid changes its state when the temperature changes environment. In particular, in winter the oil becomes thicker and the movement of the door leaf becomes slower. In summer, everything turns out the opposite, so you need to prepare the door closer to the required level. Adjusting the device is also necessary if you notice any malfunctions or you simply don’t like the settings. If the device begins to slow down or the door leaf closes too hard and quickly, intermittently, and does not close for a long time, you can try to correct all this. Things are somewhat more complicated when the device fails, since a simple adjustment will no longer be effective and repair work will be required.

Instructions for setting up a door closer with your own hands

To adjust the device, it is not necessary to invite a specialist. All you need is a minimum set of tools and certain skills. The whole procedure will take minimal amount time and will make it possible to achieve the desired result by following the steps listed below.

- Before you begin the procedure itself, remember that the main thing is not to overdo it with the control valves (screws). It is acceptable to make only 2 turns, then difficulties may arise. The oil in the pressure reservoir may spill out and hydraulic system The closer will eventually lose its functionality.

- To adjust the speed of closing the door leaf, you need to learn only one tendency - by twisting the valve in a clockwise direction, it will gradually decrease. If you perform the action in the opposite direction, the closing speed will increase.

- There is a solution to the problem of only one person being able to get through. Since there is a third valve, the adjustment of which can ensure the door remains in a stationary position for a certain time. Consequently, even a group of people will be able to freely enter the room.

- Such a problem as a lack of effort to completely close the door leaf is eliminated by adjusting the valves responsible for the closing speed.

The key problem when adjusting the closer may be choosing the ideal solution. The main task is to close the door completely so that there are no gaps left. It is necessary to correctly select the ideal time that the door leaf can remain open. It is also necessary to make silent closing possible; hard impacts on the door frame are unacceptable. This may cause damage to the canvas. And the worst option may be the loss of functionality of the mechanisms responsible for proper operation.

How to adjust the closing force so that the door does not slam?

For self-configuration you will need a flat-head screwdriver or an Allen key. The door opens all the way, secures special valves, located at the end of the device. Full fixation is carried out with the door leaf closed. By changing the degree of tightening of the valves, you can adjust the door to extremely comfortable closing. Valve number 1 is responsible for the closing force of the door.

If a fully open door closes too quickly at the beginning, the valve must be tightened, and if it is slow and the speed needs to be increased, on the contrary, it must be unscrewed. Valve number 2 is responsible for the speed of complete closing of the door leaf (slam). Some modifications have a third valve, which adjusts all the efforts of the door closer. When properly configured, the door leaf moves smoothly, without jerking. The result correct installation and proper setup of the closer will result in a long service life.

Important! The control valves must not be turned out completely. Otherwise, they will cease to fulfill their functional purpose even after returning to their place.

How to weaken the opening?

Quite often the closer requires additional adjustment. If the mechanism is working hard, and effort is required when opening the door, you need to release the valves, the door will begin to function smoothly. The valves can be placed at the end or on front side, it all depends on the modification of the device. You can find out the location of the valves by looking in the manual, where the manufacturer indicates the location of all components and elements of the door closing mechanism.

Position open

At times there is a need for open door over a relatively long period of time. It is worth figuring out how to adjust the device so that the doors do not close, but remain open. In many modifications of closers there is an auxiliary hold open option for this. To set it to this mode, you need to open the door approximately 90 degrees, and then tighten the specialized lock. After such simple actions, it will be possible to leave the door leaf open when opening it to the configured degree. A special lock in the device will be activated and will hold the door in this position as long as necessary. If you need to close the door, you just need to pull it towards you, and it will be removed from the latch. If the door is not opened all the way, it will move in the same way as always, without stopping.

The purpose of the mechanisms is to ensure smooth opening/closing of door leaves with adjustable force and speed, and to pause in the open position to facilitate passage for people with special needs. Such door functioning parameters eliminate knocks and mechanism breakdowns due to excessive mechanical forces. To complete the assigned tasks, energy is required; it is accumulated during the opening of the door leaf. We will look at how the mechanism works in detail below, but now we need to familiarize ourselves with their types.

Table. Types of door closers

| Closer type | Brief description and technical parameters |

|---|---|

| Traditional and simplest model. When the door is opened, the metal lever compresses the spring, then it returns to its original state and closes the door. Spring closers very reliable and cheap, but they have one unpleasant drawback - the doors slam a lot. This not only irritates users, but also causes damage to door locks. |

| A more modern mechanism has a metal rod sliding (slide) along a special guide. Most often used for interior doors with low weight. Heavy blades have a significant moment of inertia, which complicates the operation of the mechanism. |

| A more reliable and most common option, a very reliable device. Universal purpose, has no restrictions on the weight and size of doors. |

When buying any mechanisms, you should always keep in mind a simple dependence: what simpler device- the more reliable it is. This is an axiom for all engineering designs, keep it in mind when making your final decision.

Prices for door closers

Door closers

Types of door closers by installation method

The mechanisms can be fixed in different places; consumers independently decide which type suits them best.

The device of the closer mechanism

Without understanding the structure and operating principle of the mechanisms, it is very difficult to make adjustments correctly. In order to foresee the consequences of unqualified intervention in factory adjustments, you need to become familiar with the purpose of each element of the closer.

- Toothed gear. The main element of the mechanism is made of durable alloy steel, the surface is hardened by high-frequency currents. Engages with the closer piston. The height is adjusted with a special screw; a metal rack is attached to the gear in the upper part to transmit forces.

Gear - main element mechanism

- Piston. Performs reciprocating movements inside the housing, simultaneously or alternately closing/opening technological holes for oil flow. One part of the piston rests against the spring. The piston has perfectly ground surfaces that slide along the cylinder. During movement, the piston teeth rotate a gear that controls the position and mode of movement of the doors, and oil flows from one cavity to another.

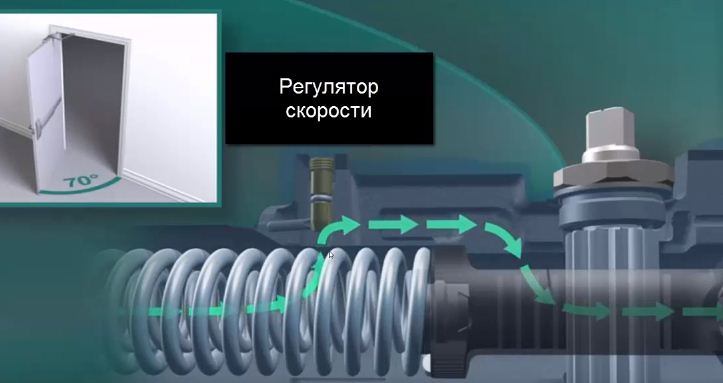

- Speed controller. A special screw with an oil seal is installed in the housing on a thread. When tightening, the technological opening for oil flow decreases, and the change in volume occurs more slowly. The door opens with difficulty, and the angular velocity decreases noticeably.

- Ride control. Before reaching the end of the cylinder, the piston closes the hole responsible for the speed of closing the doors and opens the next one, responsible for the smoothness of movement when touching the door frame. The principle of regulation is no different from that described above, you just need to tighten/unscrew another bolt. The closing speed changes just before the door leaf closes.

- Protection system. The piston has ball valves on both sides; their springs are calculated based on maximum forces. If the doors are exposed to critical loads that are not provided for in the operating recommendations, they are triggered. safety valves and oil flows from one part of the mechanism to another. Due to this, the likelihood of mechanical breakdowns of gears and levers is minimized, and the closer does not come off the door leaf.

Step-by-step adjustment instructions

For example, we will consider only one model of mechanisms. Having studied the algorithm of work, you will be able to regulate other types; they have no fundamental difference in design, the differences are only external.

Step 1. Remove the decorative housing cover. It is fixed with latches; to release it, just pull it towards you.

Step 2. Adjust the long rod; it should be positioned strictly parallel to the channel. The adjustment is done in several stages.

Practical advice. For better compression, the rod should be set at an angle of approximately 8° to the channel. Due to this position, the spring is further compressed, and a constant force is applied to the door leaf.

Step 3. Attach the rod to the sliding channel. It must be pressed, rotated 8°, and the cutout must be hooked onto the technological protrusion. Use a hex key to tighten the fixing screw. Check the functionality of the doors - if they are great strength hit the box, then you need to make additional adjustments.

Step 4. Adjust the speed of closing the canvas. This is done with screw “C”; when you tighten/unscrew it, the throughput of the hole changes. There is a valve at the bottom of the screw that controls the degree to which the hole is closed. Achieve the speed you need; adjustments will have to be made several times to achieve the desired effect.

Step 5. Using the “L” valve, adjust the closing speed before touching the box. This parameter eliminates loud claps of the blade, reduces the load on the lock, and increases the service life of the elements. The final closing speed should be approximately two times less than the main one.

Step 6. The opening force is regulated by the bottom valve “B”. This so-called brake does not allow drafts, animals, or small children to open the doors. Another task of the brake is to limit the maximum opening and prevent sudden shock loads on the mechanism.

Screw “B” regulates the door opening force

Step 7. Modern devices have a very important function - closing delay. The doors remain open for some time, during which time people in wheelchairs enter the room, parents with small children and strollers, and the elderly calmly enter. The function is regulated by valve "D". Achieve the required closing delay by changing the size of the passage opening. The smaller its area, the less oil it lets through, the longer the delay.

The door closing interval is adjusted by screw “D”

Step 8. Adjust the closing force. The fact is that quite often when closing the door with a door closer door lock does not latch.

Important. Before making adjustments, check the functionality of the door. Quite often, problems with closing can arise due to its breakdown.

The closing force is adjusted using a large spring, which is compressed by a special screw.

Check all adjustments again. If you are completely satisfied with the operation of the closer, then replace the decorative protective cover of the mechanism. Subject to the operating rules, the closer long time works in the set modes.

When making adjustments, never completely unscrew the screws. As you already know, the mechanism’s container is filled with oil; when the screws are unscrewed, it will flow out. It is very difficult to fill the oil yourself without air. And if there is air, the work of the closer will become unpredictable. The doors then slow down for no reason, then speed up, each time the movement algorithm changes. Simple adjustments do not correct the situation.

How to increase service life

There are a few simple tips, the implementation of which eliminates the possibility of mechanical breakdowns and extends the life of the devices.

- Always take into account the conditions for using the door closer. If it is installed on the doors of public buildings, the frequency of opening/closing increases sharply. In addition, not all visitors handle doors carefully; strong mechanical stress may occur. For such needs, you need to choose the most reliable door closers. Attention is drawn secondarily to the number of adjustments; the main factor is mechanical stability.

- Make sure that the door is used for its intended purpose and does not serve as a barrier for animals, a toy for children, etc. There is no need to increase the weight of the door leaf. We have already mentioned that the greater the weight of the doors, the higher the inertia indicators, and they have an extremely negative effect on the mechanism.

- Never undertake installation or adjustment of the device without reading the instructions, without understanding the principle of operation of the closer elements, without anticipating possible consequences their interventions.

- Do not buy mechanisms from unknown companies. The fact is that they have many connections that require high precision machining of the surfaces of the parts. At the slightest deviation in technology, oil leaks appear. It is impossible to correct the problem by simply adding oil; complex repairs must be made. This requires a lot of time and money, and the result is still unknown. It is much more profitable to immediately buy expensive but high-quality products from well-known European companies.