Sliding door systems occupy a special place in the design of premises. Their functions combine several advantages - convenience, efficiency and originality. The installation of such doors differs significantly from the installation of conventional swing models. You can get acquainted with the principles and features of the installation of sliding systems by reading the section - installation of sliding systems interior doors DIY: assembly video for non-professionals.

Do-it-yourself single-leaf sliding door installation

Types of sliding doors and their equipment

Designers do not skimp on ideas, developing new models of sliding interior systems. They may vary in the following ways:

Double sliding doors made of translucent glass between the kitchen and living room

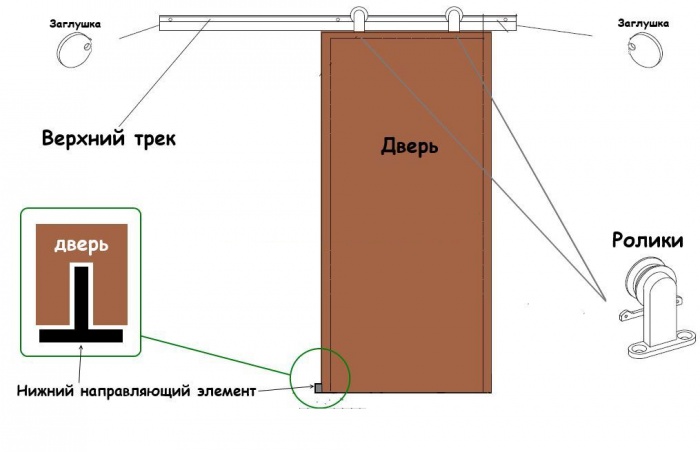

Sliding doors, the top guide of which is attached to the ceiling, visually increase the height of the room. Designs that do not involve a bottom rail will maintain the unity of the floor covering of the entire room.

In the open position, the cassette sliding door leaf is located in a niche inside the wall

When purchasing sliding interior systems for DIY installation, make sure that standard equipment is available. It includes:

Double sliding doors with double row of top rails

The model of roller mechanisms and their number depend on the weight of the door leaf. If you purchase a door without a set of fittings, ask what is its weight.

DIY tools for installing sliding doors

To install sliding interior doors with your own hands, there is no need to have a special tool. For DIY installation you will need the usual “standby” kit:

White wooden sliding doors with glass inserts

As for accessories, you can stock up on a number of wooden wedges and a square beam measuring 50 or 40 (mm) for attaching the guides.

Installing sliding interior doors with your own hands: video tutorial for non-professionals

As can be seen from the video, even a non-professional can install a sliding interior door with his own hands. As soon as desired design The door has been selected and the appropriate components have been purchased, installation can begin.

Sliding doors as an element of space zoning in the interior

The most popular models for do-it-yourself installation are sliding interior single-leaf doors. The assembly and fastening of such doors is relatively simple, and at the same time they have common features installation with other types sliding doors:

Step 1: taking measurements of the doorway

Step 2: Assembly door design and pseudo-box

When you decide to install a door model that moves along the wall, plan the arrangement of furniture and accessories so that they are not in the area of the door movement.

Schematic representation of the movement of a sliding door along a wall

Step 3: installing the pseudo-box in the opening, aligning it vertically and horizontally

Step 4: Attaching the Top Rail

Step 5: attaching staples to the upper end of the door leaf

Don't skimp on accessories! When choosing a sliding mechanism for an interior door, make a choice in favor of quality products. This determines how softly, silently and how long the mechanism will function.

Step 6: Installing the Roller Carriages in the Top Rail

Step 7: Adjusting the Position of the Roller Carriages

Step 8: Attaching the Bottom Guide Rail

- All that remains is to use a decorative strip to hide the beam with the guide rail, attach the trim and plugs at the fastening points.

Sliding systems with a sliding door inside the wall. Do-it-yourself installation specifics

For interior sliding systems, the doors of which are “hidden” into the wall, the installation technology is somewhat different. This does not concern the basic principles of assembling and fastening the sliding mechanism, but rather the calculations and preparatory work for constructing a false wall. The door will be rolled into the niche of this wall or a cassette will be installed (if you purchased a door with a cassette block):

Step 1: arranging the frame for the double wall partition

Step 2: designing a space inside the wall for the sliding door to move

Step 3: covering the false wall with plasterboard and finishing

When determining the installation location of the limiter on the top rail inside the cassette, do not forget to take into account the thickness of the decorative trim that will frame the opening.

Schematic illustration of the location of the door leaf inside the wall partition

Step 4: Sliding door sliding inside the wall

Installing sliding doors with your own hands is a process that does not require professional skills or effort. Enough to have necessary minimum tools and feel free to begin installation yourself. Accurate measurements, following the recommendations - and your room will be transformed by a functional and stylish sliding door. Besides, self-installation will “balance” the costs of purchasing structures that are more expensive in price than swing analogues.

Quite often we are faced with the problem of lack of free space in rooms. We can solve this situation in apartments by installing sliding doors.

Already now, when planning an apartment, we always take into account our space and try to save space when implementing interior design ideas. You can install it yourself, without even involving expensive specialists.

So, we will talk about how to install such a door, what they are like and what you will need for this.

First choose the sliding door you like

Follow simple instructions you install such a door without special skills and tools.

What tools will you need?

You will need liquid nails, wooden blocks which we will use as spacers (various sizes will be needed - 5 x 45, 5 x 80, 5 x 110), plastic dowels, as well as nails (size 40 mm and small ones to complete the work).

To install sliding doors, prepare the following tools:

- (size is better than 1.8 m),

- hacksaws for metal,

- wood hacksaw,

- do not forget a screwdriver (can be replaced with screwdrivers),

- wrench,

- hammer,

- as well as a hex key and a mallet with a rubber striker.

System installation, door installation

The choice of design for your future doors depends on your preferences and wishes. These doors look great various interiors and rooms. Therefore, with their help, you can perfectly transform the room. Installation of such systems is quite simple and you can handle it yourself. However, for example, systems weighing over 100 kg or glass sashes are more complicated work and it is better for specialists to work here.

It is better to mount a sliding door in ready-made version than for individual components. So much more convenient and easier. Therefore, it is better to choose a ready-made design right away. And then we start the installation.

First you need to fix the top

We place the door leaf tightly against the wall next to the opening where we will install the sliding door. On the wall we draw a strip along the top line of our door with a pencil, for example. If the floor is uneven, then the line may “walk” a little. Therefore, we re-mark after we have installed our door in the opening. We also mark the upper level of the sash on the wall.

It is very important to ensure that our line drawn along the top of the door must be strictly horizontal. After all, we then measure 7 cm from it and draw another strip - this is for the upper guide rail. If the lines are not straight, your doors will become skewed and may not move smoothly over time.

Above our second drawn strip (which is drawn 7 cm higher than the first) we place a 50*50 mm block and attach it with self-tapping screws directly to the base. The length of the bar should be 2 times greater than the width of the opening. The block should be pressed very firmly against the wall. If the wall is uneven, then use a couple of extra screws. Be sure to double-check the horizontal line with a building level.

The next step is to install the guide. It must be attached to the bar from below. First, let's calculate the mounting location on both sides. We divide the thickness of the door leaf in half + a small distance from the wall (this is no more than 3-5 mm). We mark these points on the block and fix the guide with self-tapping screws on both sides. Do not press too hard so that finishing installation You could check the distance between the wall and the sash and then tighten it completely. The distance must be sufficient for the door leaf to move freely and without problems along the rail. Otherwise you will have to repeat everything again. I repeat once again that the important and main condition for installation is a perfectly horizontal and straight position of the guide, no matter how uneven the walls are. After all checks, the guide is finally secured.

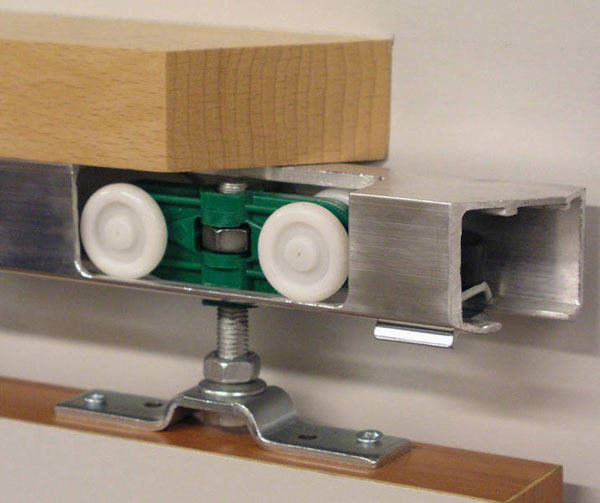

After that, we assemble the carriages and test the ride. We do not secure the bolts in the carriages and rollers completely, but so that they protrude slightly from the hole. In this state, we insert the carriages into the guide and carefully check the movement. Does it move smoothly along the guide, or does it move freely in the direction of movement? Nothing needs to be lubricated. After checking, we attach limiters with rubber shock absorbers along the edges of the guide.

Next we need to secure the bottom groove

We retreat 15 mm from the edges of our sash and in this place it is necessary to drill a hole up to 2 cm deep and 7 mm in diameter. This hole is drilled from both sides. Strictly in the middle of the sash on the end side it is necessary to cut a small groove for our lower guide. We cut the groove 2 mm wider than the guide itself and about 18 mm deep. To cut the groove, you can use a drill, parquet saw or router. It is quite difficult to make a perfectly even groove at home, so you can use a U-shaped profile or a pair of slats as a guide.

Now we need to install the mount to the carriages on the door. We attach them in the middle of the door leaf, retreating 2 mm from the side end of the door leaf. It must be installed in such a way that the semicircular cutouts face the wall.

At this stage, you need to call a friend! We need to install the door leaf itself, so we need one more person. We place the door leaf against the rail, lift it slightly to align the carriage bolt and the cutout on the bracket. We leave the adjustment washer outside the bracket, and insert the bolt into the hole for fastening. Do not fully tighten nuts on bolts.

Now we must move the door slightly away from the wall, while holding it in order to install the lower guide into the cutout we prepared in advance. We return the door to its original position, while moving the guide knife to the open position. We fix the position of the knife on the floor at its largest length. Now we begin to adjust the distance from the door and the wall - this is no more than 5mm. Self door leaf remove from the top rail.

In small rooms, every meter of usable area counts. That is why many homeowners are replacing swing doors with sliding ones. Installing sliding doors with your own hands is quite simple. However, the mechanism for such a design costs almost the same as the canvas. Such expenses are justified if it takes up too much space; in other cases it is better to install a swing model.

Sliding sliding doors have very low sound insulation, since they do not fit tightly to the wall. Much better hide the noise of the structure, installed in the pencil case. However, they do not reach the soundproofing of the swing door.

Types of sliding doors

Retractable structures differ in the type of movable mechanism. On this basis, they are divided into rail and suspended. Each model has its own pros and cons.

Hanging type model on the top rail

The suspension mechanism consists of a square profile with a groove, inside of which there are two curved strips. The rollers attached to the product ride along these slats. The guide is made of metal, like the rollers. But they have rubber or plastic linings that provide a soft and quiet ride.

When installing a sliding interior door on a rail, no devices or mechanisms are installed on the floor. All fasteners that are on the canvas are two rollers on top. They move along the groove due to special wheels. Such doors are considered one of the easiest to install. Installing a sliding door includes the following steps:

- installation of profile rails;

- installing rollers to the top of the door;

- inserting the product into the rail groove;

- installation of gate valves to limit rail movement;

- inserting the lower roller into the groove and installing the door;

- installation of decorative overlay on fittings.

The door fastening itself is very simple; in addition to the rollers and rails themselves, the kit includes plugs and fasteners. A product with a top rail has extremely low sound insulation rates. Therefore, it is not recommended to use such structures in living rooms.

Sliding structures on rails

There are two fastening rails on sliding doors. Movable rollers are mounted at the top and bottom. This method of fastening makes the product very stable, so it can be shaken.

Note! The metal profile of the fasteners is constantly clogged with dust and debris, which complicates cleaning in the house.

Mounting options

Regardless of the type of fastener, the installation of sliding interior doors can be:

- Kupeynaya. The rollers are installed above the door leaf in the opening. The guides should fit tightly in the groove.

- Cassette. This option is considered the most labor-intensive and costly. A niche in the wall is equipped for the product, in which a guide is placed. When opened, the canvas is pushed into the wall. Such designs are the most effective at saving space.

- Cascading. Similar designs are very popular in Asian countries. The model consists of 2-3 canvases. One is stationary, while the others ride on rails and move behind it.

If you plan to install sliding doors yourself, choose a compartment design. The models are easy to assemble and highly maintainable. The main feature that is necessary for installing an interior door with your own hands is a smooth opening.

You cannot place anything near the wall to which the base of the sliding door is moved, otherwise the movement of the door leaf will be disrupted. A significant disadvantage of the models is their low sound insulation. This is due to the fact that sliding doors are installed with a gap. Without it, the canvas will scratch against the wall.

Cassette structures provide the best access to room space. Inside the niche you can install soundproofing materials that will hide the noise. However, installation of such a model is possible only at the stage of repair or construction. In addition, a decorative wall is assembled for the rail, and this deprives the room of useful space.

Cascade products are a modification of compartment structures. The main difference is larger number guide rails. Installing such products is the most difficult, as high precision is required. Cascade structures are classified as premium for their complexity and aesthetics.

Installation Features

You can install sliding interior doors with your own hands even if you don’t have specific skills. Installation instructions are included with each product. By following it, you can complete all the work yourself. Below the assembly process is described in more detail than in the standard instructions.

Do-it-yourself sliding door installation

The opening, regardless of the fastener design, the place for the structure must meet the following characteristics:

- Smooth surface on all planes. The walls of the opening should not have serious differences or flaws.

- High load-bearing capacity.

- Both the walls and the opening must be pre-finished with a leveling compound and decorative coating.

After leveling the opening, you can proceed with the installation. The first step is to attach the rollers. Depending on the manufacturer and model, fasteners may have their own characteristics. To assemble some products you need to step back 15-20 cm from the edge, but most often the rollers are mounted right at the edge.

To begin with, markings are made on the canvas for fasteners.

Important! Make sure that the distance from the edge to the roller is the same on both sides.

At the marking site with a drill, holes are drilled 1 mm smaller than the diameter of the fastener. After the grooves are ready, fix the plates. Self-tapping screws are used as fasteners, their length must be at least 75 mm. The greater the weight of the canvas - the longer the fasteners. Special support holders are mounted into the plates, into which rollers are inserted. On the sides of the canvas, fasteners must be fixed with plugs.

The rollers come with pins. The movable elements themselves are screwed onto them. If the model is not equipped with handles, they must be purchased separately. It is recommended to install the handles before installing the product in the opening. In a model without a groove, markings are made with a pencil and the material is removed along the contour with a carpentry tool. Fittings are attached to the resulting hole.

Note! Only submersible fittings are suitable for sliding doors.

When the canvas is ready, the rail is attached. The easiest way is to screw the guide to the block, and not directly into the opening. To do this, take a wooden plank of square or rectangular cross-section with a side of 60 cm. The length of the block should be twice as long as the door itself and a margin of 5-10 cm. The rail is cut along the length of the block.

The guide is screwed to the block with self-tapping screws from 85 mm. The minimum number of fasteners is 4, the more often the better. The recommended step between screws is 10 cm, the same distance is made from the edge of the canvas to the first fastener.

Next you need to measure the height of the bar. The rail is threaded onto rollers of the canvas and the height is measured. Using this value, holes are made on the wall for attaching the guide rail. The canvas should not stand on the floor. A distance of 8-10 mm is left from the floor to the structure itself. If there are no coverings on the floor, the thickness of the floor finishing is added to the value.

The level is used to adjust the mark for mounting the bar. For this, fasteners from 12 cm are used, but anchor bolts are more reliable fasteners. IN concrete walls dowels are used.

Markings for the guide are made with a thin drill or nail. After that, holes are drilled for dowels or screws and the timber is mounted. The final stage- insertion of sliding doors into the rail. After rolling up the structure, plugs are placed on the sides of the fittings; they protect the structure from slipping.

When the door is open, a flag roller is screwed onto the floor. It regulates the movement of the blade along the vertical axis.

The installation of a decorative overlay on the fastening profile will give the structure an aesthetic appearance. It is placed on finishing nails or self-tapping screws with decorative plugs. Screw the cover directly into the block.

To install a sliding structure, more materials and tools will be required. If you want to learn how to install sliding cassette doors, watch the detailed video instructions:

Almost any panel can be attached to a rail and a sliding door can be constructed. But for the system to function without failures, it is necessary to install high-quality fittings. Durable fasteners and rollers ensure long term door service. Therefore, there is no need to save on accessories.

The canvas itself can be made independently. The cheapest option is a frame made of timber with a body made of plywood or chipboard. A solid product made of solid or laminated wood looks most aesthetically pleasing in the interior. However, the assembly of such a product will cost more. Products made from particle boards are covered with a film or a laminating surface. Wooden panels can simply be sanded and coated with protective compounds.

It is very difficult to design a roller mechanism on your own. If you don’t have a special tool, including a cutter, you won’t be able to make the fittings yourself. It is much easier and cheaper to purchase a ready-made product.

The peculiarity of sliding doors is that when opened, they do not take up useful space in the room and save space, and therefore everyone gives preference to them more people. Today, such doors can be glass or made of other materials, such as wood.

The peculiarity of hinged structures is that they can have a different number of sashes. This allows you to completely divide the room into two different rooms. You can also isolate the room from other rooms

Kinds

Before you start choosing sliding doors, you must first understand their design. This will make it easier to install such a door if you install it yourself.

There is a difference between a sliding door and a regular one. It lies in the fact that For ordinary doors, the leaf is connected to the frame. At sliding mechanism there is no such connection. These are two separate parts that can perform different functions and are independent of each other.

In ordinary doors, the frame is the main supporting structure on which the door leaf is hung. In swing it individual elements, and the box plays a more decorative role, giving the opening a beautiful appearance.

The bearing role in single-leaf swing systems is played by another element, which is installed on the side of the door on the wall. The door leaf moves along it. This usually happens with the help of rollers and guides.

As you might guess, guides and wheels are the main part of the swing structure. It is arranged quite simply: rollers move along an aluminum rail, which, in turn, are attached to the canvas. The latter simply hangs on such a profile and moves along it with the help of rollers.

There are also special stops in the profile that are installed additionally. It is because of them that the canvas cannot move more than the prescribed distance to the side. The limiters do not allow the door to move further in both directions.

Exactly like this simple design swing doors makes their installation quite simple and does not require special preparation. That is why many residents of both private houses and apartments install such systems today.

Advantages and disadvantages

Initially sliding systems were quite fragile and unreliable. Also, the sashes did not move well along the slats and sometimes got stuck, which caused a lot of unpleasant moments for the owners. Now everything has changed, as high-quality fittings and other elements of the system have appeared.

Advantages of modern mechanisms:

- They do not open in drafts.

- Save space in the room.

- Possibility to choose different door materials.

- You can implement any design innovations.

- There are no elements that creak.

- Safety.

- Harmonious combination.

There are also disadvantages to sliding systems:

- Cannot avoid cracks.

- They are relatively expensive compared to conventional systems.

- Poor installation can lead to the fact that the sashes will not move well on the slats.

- There must be free space on the side where the sash will move.

- When the door is hidden in a niche, a lot of dust can collect there, which will be difficult to remove.

Based on the above, it turns out that before making a decision to install such systems, you need to carefully weigh and think through everything, study examples. After this, it will become clear whether to install such a system or not.

Installation features

Typically, installing such mechanisms is not as difficult as it might seem at first glance. Installation of interior doors will take 2-3 hours if available minimum experience. This way you can also install furniture mechanisms in cabinets or on bedside tables. But usually this will need to be done in an apartment when the cabinets are built into the walls.

Automatic parts allowed, making the process of opening or closing doors even easier. But it requires additional elements for installation and cannot always be done on your own. Therefore, such structures will be discussed separately.

In order to install the system immediately and correctly, you first need to take measurements and make calculations. Initially, you need to understand that sliding systems can be of the following types:

- The canvas moves along the wall.

- The canvas moves in the wall.

In the first case, the entire structure will be supported by a profile that is attached to the wall. In the second case, the web can also move on the lower suspension. But this method has one drawback, namely, that there will be a threshold in front of the doors. Also, sometimes two of these types of fastenings can be used at once. This ensures the reliability and durability of the system.

It is important to remember that in many cases the cost of the mechanism itself depends not on the type of wood and the material of its manufacture, but also on the quality of the fittings. If you buy inexpensive trim or handles, you can save a lot.

You need to know that when you plan to make a door that will move inside the wall, you can not knock out the opening, but simply make an overlay wall from plasterboard. This will reduce the time required to complete the work. This will also help keep the wall structure the same and intact.

Mechanisms

Sliding structures can be equipped different types mechanisms. Among them are:

- Hidden. The canvas moves inside the wall. Everything for such a system should be prepared at initial stage. To do this, you need to knock out a hole inside the wall or put sheets of plasterboard on top of it. As a result of such actions, the thickness of the wall can be slightly increased, which will take up the useful area of the room. Also, debris and dust will accumulate in such niches, which will make cleaning difficult.

- Open. Installation of such a mechanism can be carried out at any time. It is important here that there is an opening away from the doors and enough space for installing guides. There is no need to carry out any work to rebuild the wall. In this case, many options for installing guides are assumed, which makes it possible to choose best option for one occasion or another.

Guides

The last thing to consider when making an installation decision is sliding structures, these are on the profiles along which the door will move. They can be placed at the bottom or at the top. It all depends on the design features. They can also be placed on both sides at the same time:

- Upper. This option for installing profiles is the most popular. It turns out that the canvas will hang on the profile along which it moves. This can be done when the weight of the canvas itself is small. Such guides can last longer, removing dust from the rollers will be simplified, and they will not jam.

- Lower ones. Such guides are rarely used, as they are subject to deformation during use and therefore may not last long. Such skids will require constant cleaning from dust and debris. The door will not slide smoothly if it does not have support at the top.

- Combined. They are used in cases where the system is large and heavy. This ensures a smoother glide through the openings.

Required Tools

To avoid any hiccups in the work, before you begin installation, you should purchase all the materials and prepare the tools. They can be bought at any specialized store. Without them it will be impossible to do this work.

Will be needed:

- Pencil case for sliding door;

- Fastening;

- Pens;

- Drill;

- Correct guide;

- Cassette in the wall;

- Niche fasteners;

- Liquid Nails;

- self-tapping screws;

- anchor;

- Racks;

- Canvas;

- Wooden beam.

It is also worth purchasing a system on which the door will move. This can be a system made of plastic, metal or aluminum. It is also important to buy high-quality rollers made of plastic alloy so that they do not jam and move smoothly along the guides.

Step-by-step instruction

If the structure has a complex shape or heavy weight, then the presence of a specialist will be required to perform such work. Therefore, it is important not to start such an event on your own, as this can lead to disastrous results and affect costs. If you don’t have the skills to do this kind of work, you can only install small systems yourself.

When a ready-made set of doors was bought, such work can be done quite simply. It doesn't require a lot of effort and time. The system will have everything necessary to carry out such work. It will only take prepare and install everything correctly.

If you need to install the system according to your project, then such work will be quite difficult to perform. Here it will be necessary to individually select all fittings, guides, hinges and other elements for this or that case.

Typically, the installation of the mechanism begins with the opening. To do this, you need to dismantle the old canvas and put the opening in order. You can use cement to level the walls or plastering work. All irregularities and cracks must be removed from the wall surface. Drywall must be cut evenly along the edge, and excess cement and a layer of plaster should be removed.

In order for the guides to run parallel to the floor, it is necessary to knock out a straight line above the opening, on which the guide rail will be attached. If it is still attached to the wall decorative element, then you will also need to leave a place for it and place it exactly above the door.

It is also worth checking the top element of the opening in relation to the floor. They must be parallel. Using a plumb line, you need to check the opening itself and its perpendicularity to the floor. A deviation of 5-10 millimeters is allowed. But at the same time, the smoother the wall is, the more tightly the canvas will adhere to it.

Next you need to put the box. It will be difficult to cope with such work on your own. A partner will be required. The box must be installed in the opening and leveled there using wedges. It should be level with the floor and walls. After this, the box should be secured with anchors or screws. You need to tighten it carefully so as not to move it.

Next, you will need to check the correctness and parallelism of the guide attachment line relative to the door opening. This needs to be done, since the floor may not be very level, especially in apartments. If the line is correct, then it should be the same distance from the opening at all corners.

The guide is attached along this line. To ensure that the canvas lies tightly, the guide should be attached to the wall as rigidly as possible. Self-tapping screws and anchors are used for this.

Limiters

After such work, each carriage must be attached to the door and inserted into the guide. Limiters are also placed there. They should protrude slightly from the rail so that the rollers do not jump over them. You should also make sure that the rollers move freely in the rack.

To ensure long-term operation of the rollers and their free movement in the rack, you should not lubricate them with anything, as dust will accumulate there.

canvas

To correctly and quickly install the canvas with your own hands, you will need an assistant and a diagram. The canvas must be placed tightly against the guide and the rollers must be inserted inside. Then they are attached to the canvas so that they sit there firmly. Wherein It is important that the gap between the door and the base does not exceed 5 millimeters. If this does not happen, then the canvas must be tightened using self-tapping screws.

Installing sliding interior doors can save space in apartments and private houses when owners want to expand their living space. You can install the structure yourself if the owner of the house has carpentry skills and necessary tools.

There are several types of design:

- sliding;

- cascade;

- folding;

- radius sliding.

Making sliding doors with your own hands is easier than other types of partitions. This is due to the simplicity of the design, shape, installation of the canvas and installation of fittings. Depending on the width of the opening, the sliding door device includes 1 or 2 panels, which move on special rails along the wall. Partitions can be independently made from different materials.

Advantages and disadvantages

An interior single-leaf or multi-leaf door has the following advantages:

- saves room space;

- visually increases the size of the room;

- there is no threshold;

- You can divide a large room into zones.

The disadvantages include:

- poor sound insulation;

- the need to monitor the cleanliness of the rail;

- easy penetration of odors between rooms;

- the need for precise adjustment of all structural elements.

Before you learn how to make a sliding door, you need to prepare materials and tools.

Materials and tools

You will need the following tools:

- tape measure, ruler, square and pencil;

- jigsaw or a circular saw;

- screwdriver;

- drill;

- drills of different diameters for wood and concrete;

- self-tapping screws;

- roller mechanisms;

- construction plumb and level;

- milling machine;

- sandpaper or sander;

- chisel and hammer.

Canvases can be made from the following materials:

- plain or laminated chipboard;

- strained glass;

- solid wood;

- combination of several materials.

The weight of the structure depends on the material of manufacture. To install sliding doors with your own hands, you need to select mechanisms based on this indicator. The material for the canvas is selected based on the budget of the owners and functional purpose doors.

How to make sliding doors with your own hands?

For the manufacture of glass partitions skills to work with this material are required. If they are missing, you should contact a professional. To work with glass you need special tools that are expensive.

It is necessary to consider how to assemble a sliding door made of wood. This material is easy to process, stronger and more reliable, has better sound insulation, frame products weigh less than solid wood, and can be made into panels if desired.

Design Features

Before starting work, you should draw up a diagram or drawing of the structure and indicate all the parameters. The design of sliding doors can have one or more leaves depending on the size of the opening. You can make a solid canvas or with panels from different material. Depending on the weight of the structure, the door can be suspended or on roller mechanisms.

Sometimes a product is installed that slides deep into the wall. To do this, dismantle part of the partition and make a drywall niche.

Preparatory work

Before making a sliding door with your own hands, you should prepare the material. Boards or bars must be processed with a planer and sanded sandpaper or a sander. You should also prepare a shield if you plan to have a hollow door inside. In advance, it is worth deciding on the method of fastening the boards. Common connections are:

- half a tree;

- tongue and groove

Measurements and markings

When making a door on rollers with your own hands, you must take into account that the door leaf should be several centimeters larger than the opening on each side. If the passage does not exceed 80 cm in width, then a single door is made. When the width of the opening exceeds 1 m, 2 canvases are made. All dimensions are transferred to beams or boards.

Manufacturing

To make frame sliding doors with your own hands, you need to make a frame. Pre-prepared beams are cut according to the drawing. If the structure includes panels, in the inner part of the frame and lintels milling machine make recesses into which the inserts will be mounted.

The joints of boards or beams are coated with wood glue or PVA. Wood should be treated with an antiseptic to protect the material from rotting and the harmful effects of insects. Additionally, the structure is coated with fire retardants, which prevent the wood from quickly igniting.

To make a sliding door mechanism with your own hands, you will need:

- upper and lower guides along which the canvas will move;

- wooden beam, to which the top rail is attached;

- rollers and fastenings corresponding to the weight of the structure;

- clamps that prevent the web from coming out of the rails.

Paneled

First, a frame is made from solid boards or laminated veneer lumber. The cross members and the mullion are made from this material. WITH inside The timber is processed with a milling cutter, making a groove for the panels. If you make a shaped cut, you don’t have to use glazing beads. When it is planned to install the latter, the surface near the groove is made smooth.

Vertical and horizontal elements are connected to each other using a tongue and groove. The tenon is cut out in the transverse parts. It should fit into the groove up to half the width of the beam. The recess is adjusted to the dimensions of the tenon so that the parts fit tightly into each other.

The panels can be:

- glass;

- plywood;

- thin boards, etc.

Inserts can be smooth or have a textured surface. In the second case, plywood or boards are used, which are processed with a milling machine. The edges of the product should be 1-2 mm smaller than the groove in the frame. This will allow the panels to move freely. When all the elements are ready, they are treated with antiseptics.

Assemble the entire structure on the table to avoid distortions. The joints are coated with glue. First, all the crossbars and panels are inserted into one longitudinal beam, then the second one is glued vertical beam. The beads are installed after assembling the entire structure and are fixed with glue.

Panel

This design can be solid, small-hollow or hollow. The first type consists of a frame and boards that are laid between the vertical elements. Hollow and shallow-hollow contain transverse elements that give rigidity to the entire structure.

First, a frame is made according to the size of the canvas. To do this, cut a beam with a section of 30x120 mm according to the drawing. The elements are connected to each other by fastening in half a tree or in a paw. The surfaces are coated with glue and clamped with clamps. Care must be taken to ensure that internal corners were 90°.

After the glue has dried, the joints are additionally secured with dowels. To do this, make holes of 7-9 mm and insert dowels pre-treated with glue into them. Then one side of the frame should be covered. The material chosen is plywood or fiberboard, which is cut to the size of the frame. The facing material is fixed with glue.

If the structure is solid, then the frame is filled with timber, pieces of MDF or other low-quality wood. All parts are glued together and additionally glued to the facing sheet. In the frame of hollow or shallow-hollow doors, cross members are installed, which are fixed with glue to the sidewalls and facing material. The second sheet is installed only after the glue has completely dried.

How to install a sliding door?

The installation of sliding doors may vary depending on the design features. Installation involves the following steps:

- preparation of the doorway;

- fastening of guide elements;

- installation of the canvas;

- insertion of handles.

To ensure proper installation, you must follow the sliding door installation instructions exactly.

Preparation of the interior opening

First of all, you need to prepare the opening. If the canvas moves along the wall, you should remove all protruding elements, level the surface, and fill the cracks. The canvas should move without obstacles. Since the design does not provide for luting, the walls are plastered. The opening should be as even and smooth as possible.

If you plan to install sliding door inside the partition, part of the wall should be dismantled. To do this, increase the opening by the width of the door leaf, and then install a plasterboard niche. The partition should fit into the wall so that only a small part of the canvas remains, on which the handle is located.

Installation of guides

If the canvas is light, it is hung only on the upper guide. If the sash is made of wood and has a lot of weight, it must be fixed in the lower runners. Since the sliding door can be installed on 1 or 2 rails, it is necessary to consider both options.

To mount the upper guide, a canvas is placed against the opening. Measure the position of the door in the closed and open state. From the resulting line, step back 7 cm and draw a horizontal line. It determines the position of the beam on which the rail is attached.

The length of the beam must match the guide. It is placed so that the middle is exactly above the upper corner of the opening from the side open door. Then the guide profile is attached.

The upper runners are fixed using self-tapping screws. Then the carriage with rollers is assembled and inserted inside the guides. It is necessary to check whether the mechanism moves freely in the rail. Stoppers are installed along the edges of the guides to prevent the canvas from jumping out of the track.

The bottom groove is made using a milling machine. It should be 1-2 mm larger than the guide knife, and the depth should be 18 mm. If the design does not provide for a bottom rail, then a flag guide stopper is installed on the floor. It should fit into the groove in the door leaf. Its task is to limit the movement of the canvas and eliminate transverse vibrations of the sash from below.

Installation of the canvas

Installation of sliding doors is carried out after installing all the guides. First you need to install the mounting brackets. They are fixed with self-tapping screws to the upper end of the door, after making holes using a thin drill. The canvas is hung on the upper rail, and then inserted into the lower guide. The carriages with rollers are connected to the brackets so that the nut and washer are on top. Then the fasteners are tightened wrench. After checking the movement along the upper guide, the blade can be installed in the lower groove.

Accessories

Installation of sliding interior doors will be incomplete without installing fittings. For such structures, mortise handles and special locks are used. Locking devices are rarely installed, since the level of protection of such mechanisms is low. To make handles you will need:

- Ruler and pencil;

- milling machine;

- chisel and hammer;

- screws and a screwdriver.

First, mark the position of the handles. They are placed at waist level at a distance of 4-5 cm from the vertical edge of the canvas. The handles are applied to the door and outlined with a pencil. A recess is made to fit the thickness of the fittings using a milling machine or chisel. You can also use a drill with a core drill of the required diameter. A hole should be made on the bottom and top sides of the handle. The wood between the recesses is removed with a chisel or router.

To install sliding doors with mortise lock, you need to use a drill to make a hole in the end of the blade. A locking mechanism is installed in the groove and closed with a special strip. In this case, the handle is not a mortise one, but a bracket. A recess is made in the opening for the counter plate. If the lock is padlocked, it is screwed with self-tapping screws to the door leaf.

To prevent dust from entering the room, special brush seals are attached to the lower end of the canvas. If the partition design includes 2 doors, special seals are additionally installed at the ends of the adjacent panels.

Installation of sliding doors should be carried out on high-quality roller carriages. Despite the high cost of the mechanisms, they significantly save money in the future. Cheap rollers quickly break down with frequent use and need to be replaced. High-quality carriages will last a long time.

The cheapest way is to make a door leaf from simple or laminated chipboard, MDF. This material You can decorate it to your taste. This can be done using varnish, paint, self-adhesive film, wallpaper or any other way.

For wooden doors You should choose material that has been dried in special cabinets. Otherwise, the structure may become deformed in the first months of operation, and then the frame will have to be redone.

Repair

Sometimes sliding door repairs may be necessary. A common failure is poor movement of the blade in the guides. To do this, you need to either adjust the roller or replace it. Sometimes debris gets into the guides, dust and dirt accumulate, which over time does not allow the mechanisms to move freely. To avoid this, you should clean the rails in a timely manner.