The first electric motor was invented in 1834 by the Russian scientist B.S. Jacobi. Over the next 30 years, work tools began to appear based on an electric motor. The first drill began working in 1868 in the office of the American dentist D. Green. Modern look I purchased the instrument in 1916, when mechanics Black and Dekker designed the body in the form of a pistol with a button in place of the trigger.

What is a drill usually used for?

The main purpose of an electric drill is to drill various materials. Calculations of technical indicators when designing new models are carried out based precisely on this task.

During operation, the electric motor rotates the chuck with the drill clamped in it. The speed of movement is regulated using a special rheostat controlled by a start button. The direction of movement can be changed by switching the reverse lever. The function of changing the direction of rotation will help if the drill jams at the exit from the material. In addition, with special attachments, the drill can be used as a screwdriver - tighten and unscrew screws.

The multifunctionality of the tool is provided for by its design.

Drills often have two or more speeds. This is achieved using a gearbox connecting the engine to the working shaft. Change gear ratio gears of the gearbox leads to a change in the rotation speed and power of the working tool.

Video: drill - a look from the inside

Power tools in this category usually have two main operating modes. Standard drilling mode and hammer drilling. Normal mode is used during plumbing and carpentry work. Impact drilling is designed for making holes in stone walls, concrete and brick.

The impact mechanism of the drill consists of two coaxially located ratchets, which, when interacting, give the working shaft additional translational motion. In this case, special drills with carbide tips are used at the end of the working part. The impact force of such a mechanism depends on the external pressure on the drill. In order for drilling to proceed quickly, a force of 10–15 kg must be applied to the body.

Preparing for work

The readiness of the drill for operation is determined by the following conditions:

- the device is connected to an outlet (for drills powered by an electrical network);

- the battery is charged and installed in the compartment (for cordless tools);

- a drill is installed in the chuck.

Attention! To make the hole smooth, the cutting edge of the drill must be sharpened. Take a new drill or sharpen an old one using a whetstone.

You can press the start button to check the power. If the cartridge rotates quickly, then the motor is supplied electricity and the tool is ready for use. If the chuck of a cordless drill spins slowly, the battery is discharged - it needs to be charged.

How to insert a drill correctly?

To correctly insert the drill into the chuck, you need to know the following. The hole intended for clamping the tool is no more than 2 cm deep. The deeper the drill is set, the more securely it will hold in the chuck. There are two types of chuck clamping mechanisms:

- manual, tightened by hand;

- key, wrapped with a key.

IN last years household models drills are equipped with a manual (quick-release) chuck - it is simpler in design and quicker to operate.

To install the drill in the chuck you need to follow these steps:

- Turn the cartridge counterclockwise. The lips should be separated by a distance of slightly larger diameter drill.

- Insert the drill bit between the jaws until it stops.

- Smoothly turn the chuck clockwise, making sure that the drill is clamped evenly on all sides.

- Tighten the jaws by hand or with a wrench.

Attention! Before drilling, turn on the drill and look at the drill bit. A correctly installed tool does not hit and looks like a smooth line.

Video: how to insert a drill and secure it

When fixing the drill in the chuck, considerable force can be applied, especially if the drill has large diameter. It should be remembered that you will then have to do the reverse operation to remove the drill or replace it with another one. When clamping the drill, look for the “golden mean”: fasten the drill securely, but so that it can be removed from the chuck without any problems. The required effort is easily determined after a little practice - muscle memory kicks in.

How to remove a drill from a chuck?

Before removing the drill, make sure that the drill is unplugged from the outlet and ensure that you do not accidentally press the start button of the cordless tool. The drill should be pulled out only after the rotation of the chuck has completely stopped.

Attention! Never brake the chuck with your hands, as this may cause injury.

If the drill is equipped with a keyless chuck, the steps to remove the drill are as follows:

- Remove your finger from the start button.

- Wait until the rotation of the chuck has completely stopped.

- Grasp the cartridge by the base with one hand. With your other hand, turn it counterclockwise.

- When the jaws of the chuck have moved far enough apart, remove the drill.

- Carefully place the drill on the table, making sure that it does not roll away.

If the drill is equipped with a keyed chuck, do the following:

- Turn off the drill and wait for the chuck to stop.

- Insert the key into the chuck hole.

- Turn the key counterclockwise so that it moves the cartridge.

- Unscrew the chuck by hand so that the jaws release the drill.

- Remove the drill from the chuck.

- Place the key in the hole on the wire so it doesn't get lost.

Video: how to change a drill

How to use a drill correctly?

A drill is a powerful electric tool that is a source of danger. Basic Rules safe work with a drill the following:

- Before starting work, securely secure the workpiece in a vice or clamps. Do not hold the part in your hands.

- Firmly secure the drill or accessory in the chuck. Tighten the cartridge by hand or tighten it with a wrench. Be sure to remove the key from the hole in the socket.

- When working with hard and massive materials, hold the power tool with both hands.

- Do not press too hard on the drill body to prevent the drill from jamming. Reduce the pressure on the drill exiting the workpiece.

- Use personal protective equipment: glasses, respirator, gloves.

- Switch modes and change tools only after the chuck has completely stopped.

- Sweep away chips only with a brush.

How to make a vertical or horizontal hole

To make a vertical or horizontal hole, you need to follow these steps:

- Mark the location for the hole.

- Install a drill of the required diameter into the chuck.

- Bring the tool and set the drill to the mark.

- Smoothly start the engine and press on the drill body.

- When the hole is ready, remove the drill without turning off the motor.

- Release the start button and wait for the cartridge to stop.

- Place the drill on a flat surface.

Attention! You cannot be distracted from work until the hole is completely ready.

How to make a hole perpendicular to the surface or at an angle

If you need to make a hole perpendicular to the surface, you can use a protractor or square. Home craftsmen have figured out how to drill a hole at a 90-degree angle to a surface without a protractor. An old CD is placed on the surface of the workpiece. The drill is aligned so that the visible part of the drill coincides with its reflection in the “mirror” of the disk. In this case, the hole will be made strictly perpendicular to the surface.

When the drill is perpendicular to the surface, the line of the drill matches its reflection in the CD

When the drill is perpendicular to the surface, the line of the drill matches its reflection in the CD

If you want the hole to go at an angle to the surface, you need to secure the workpiece at this angle. The most accurate holes will come out if you use a special stand-clamp for a drill.

Angle stand secures drill at an angle

Angle stand secures drill at an angle

How to drill metal

Drilling metal surfaces has its own characteristics. First of all, you need to choose a drill designed for these purposes. A wood or stone drill bit is not suitable for metal, stainless steel or cast iron. These drills differ not only in the grade of steel, but also in the sharpening angle of the cutting edge.

When working, there is no need to rotate the drill at high speed; the drill will slide along the surface without catching the material. The optimal speed when drilling metal is low, when the naked eye can see how thin chips are formed. The pressure on the drill can be significant, but within reasonable limits so that the drill does not break. When drilling steel and cast iron, it is recommended to lubricate the drill with machine oil for cooling.

To ensure that the drill catches on hard material, it is recommended to make a recess at the drilling point using a mechanic’s core. The drill will not move to the side.

How to drill concrete

When drilling concrete, stone or brick, a lot of dust is released, and small fragments can fly out from under the drill. It is necessary to use a respirator to protect the respiratory system and goggles to protect the eyes.

Advice. You can reduce the amount of dust by moistening the workpiece or drilling site with water.

If you need to drill concrete, then the best option would be to use drills equipped with a pobedit tip at the end. These drills do the job best and can be sharpened periodically as needed.

The impact mode is included in the design of the drill for drilling stone objects. You need to use the shock mode carefully. If you are drilling into tiles, you should not turn it on, as the impact will inevitably lead to cracking of the ceramics. The same can be said about hollow brick - it is dense, but fragile.

Attention! When drilling stone and concrete, the drill becomes very hot. Before replacing the tool, wait until it has cooled down to avoid burns.

How to drill wood

Wood is a soft and easy-to-drill material that can be easily processed and sanded. When drilling wooden products It is recommended to use special wood drills.

It is best to start work with markings, marking the location for the hole with a pencil. Next, resting the end of the drill on the intended point, turn on the maximum rotation speed and smoothly immerse the drill into the wood. If the hole is deep, from time to time you need to pull the rotating drill to the surface so that it can free itself from the chips.

Often in modern life you may be faced with the need to make a hole in plastic. Basically, plastic is drilled in the same way as wood, since it is a soft material. Some synthetic materials (for example, ebonite, textolite, caprolon) have great hardness. To process such plastics, it is better to use drills designed for metal.

How to make a groove in a wooden board

If you need to make a groove in a wooden board, you can do this with an electric drill.

The groove in the board is made with an electric drill

The groove in the board is made with an electric drill

To make a groove, you need to do the following steps:

- Take a wood drill whose diameter corresponds to the width of the future groove.

- Mark holes along the groove so that their centers are at a distance of half the diameter of the drill.

- Drill all holes to a depth of 2–3 mm - this way the drill will not lead away.

- Drill all holes all the way through.

- Use a file to remove the jumpers (if any remain) and smooth out any irregularities.

Brick - pretty soft material, so its drilling can be done with a conventional electric drill with an impact function.

A simple drill can drill through brick

A simple drill can drill through brick

Drilling brick wall is done as follows:

- Mark the location of the future hole with a pencil or marker.

- Place a core or old drill on the mark.

- Apply 2-3 blows with a hammer so that a depression remains on the brick - then the drill will not move away.

- Place the drill in the drill and turn on the impact mode.

- Drill a hole by gently pressing the tool.

Note. If the finished hole needs to be more than 10 mm, it is recommended to first drill the hole with a drill of a smaller diameter - 6–8 mm, and then drill it to the desired diameter.

Video: drilling a brick wall

Basic drill malfunctions and ways to eliminate them

No matter how perfect the technology, sooner or later, there comes a time when the technological resource is exhausted, and one or another part requires replacement.

An electric drill is no exception. Here is a list of possible, most common problems:

- Motor malfunction (power supply is OK, but the motor does not rotate).

- Wear or burning of the carbon brushes (the brushes spark strongly when the device is operating).

- Failure of the engine support bearings (the hum of the motor is heard, but there is no rotation, or the cartridge rotates intermittently, with a grinding noise).

In addition, the reasons for the unstable operation of the electric drill may be related to the integrity of the power cord or a stuck start button. Such problems can be solved by replacing the cable and preventatively cleaning the button from debris and dust.

To repair a drill at home, you will need many special tools, including electrical ones. If they are not there, it is cheaper to send the drill to a service center for repairs. Replacing carbon brushes is within the capabilities of a home craftsman. In all new drill models, the designers have provided quick access to the brush attachment point and easy replacement.

The brushes are hidden under a cover above the engine commutator.

The brushes are hidden under a cover above the engine commutator.

Drill attachments and their installation

In addition to drilling holes, an electric drill is capable of performing many other diverse operations. For this purpose, various attachments have been developed and produced, with which you can grind, polish, cut or sharpen. All attachments are attached to the drill chuck, just like a regular drill.

Polishing attachment

Designed for polishing surfaces using abrasive materials. This could be sandpaper or felt base, onto which GOI paste is applied. The nozzle is a rotating flat surface, which is used to process the sanded material.

Replacement sheets sandpaper attached with Velcro

Replacement sheets sandpaper attached with Velcro

Attachments for rough cleaning of materials

Wire attachments (brush brushes) are used to clean metal surfaces (for example, pipes). They are a cylinder on the surface of which there are rigid bristles made of metal wire. They are produced with bristles of different hardness, ranging from thin wire to pieces of cable.

The bristles of the brushes are made of galvanized wire

The bristles of the brushes are made of galvanized wire

Cricket attachment

The attachment, called a “cricket,” turns the drill into metal nibblers.

The nozzle is clamped into the drill chuck - metal scissors are ready

The nozzle is clamped into the drill chuck - metal scissors are ready

Using a “cricket” you can cut holes in metal sheets up to 1.6 mm thick. The nozzle has proven itself very well in roofing works when it is necessary to adjust and cut metal sheets given form.

Video: metal scissor attachment “Cricket”

Nozzle - file

A nozzle made of abrasive material can significantly facilitate work when performing work on sharpening parts, fitting grooves and holes. Available in a wide range of sharpening stones of various shapes and sizes. Among the nozzles there are conical, cylindrical, flat, spherical stones.

Despite their miniature size, the attachments are very effective in their work.

Despite their miniature size, the attachments are very effective in their work.

Milling attachments

Drill attachments designed for milling work on wood or plastic are also called cutters. With their help, you can make a groove, groove, recess of specified dimensions.

Balls are available in different shapes and sizes

Balls are available in different shapes and sizes

According to their shape and purpose, cutters are divided into:

- cylindrical;

- disk;

- end and end;

- shaped.

The type of cutter is selected according to a specific task in accordance with the density of the material and the power of the electric drill.

Other attachments

For cutting materials

There is an attachment that can be used to cut wood, metal or plastic. The principle of operation of its mechanism is similar to the device electric jigsaw. The kit includes a set of files with various shapes and number of teeth. This attachment can easily handle cutting wooden boards up to 20 mm thick, as well as chipboard or plywood. For cutting more massive workpieces, it is still better to use a jigsaw.

For drilling large holes

For drilling large-diameter holes, special devices and tools are produced that can be used as accessories for an electric drill. To make large holes use:

- crowns - steel cylinders with teeth or coating - for wood, stone or tiles;

- feather drills - metal plates with a center and two blades - for wood and plywood;

- beam drills - long pins with spiral grooves - for drilling thick wooden beams;

- Forstner drills - a specially shaped tool with numerous cutting edges - for precise and clean holes in wood.

For tightening fasteners

Drill attachments designed for screwing in screws, bolts and nuts have become widespread and widely used. Their diversity is comparable only to the huge range of products that exists in the world of fasteners. With these attachments, provided that the speed range of the drill includes low-speed modes, the electric drill turns into a full-fledged screwdriver or impact wrench.

Set of attachments for screwing screws and nuts

Set of attachments for screwing screws and nuts

Drill mixer

We also cannot ignore such a useful practical function of an electric drill as using it as a mixer when mixing paints, plaster and other mixtures.

Using a special mixing whisk, you can successfully add the desired shade to paint at home or stir wallpaper glue. In addition, lightweight building mixtures such as gypsum or putty can also be mixed using a drill.

It should be remembered that excessive overloads on the drill can damage the main mechanism of the tool - the electric motor. It is not recommended to use a drill as a mixer when mixing heavy concrete mixtures. There are special concrete mixers and mixers for this purpose.

Attention! If the drill body is hot and the motor is humming strainedly, you should stop and give the device time to cool down.

Drilling machine

The drill can be used as a drilling machine. Drilling workpieces will be much more convenient. Stores sell ready-made stands with a drill clamp, feed lever and vice.

Drill stand turns household tool V drilling machine

Drill stand turns household tool V drilling machine

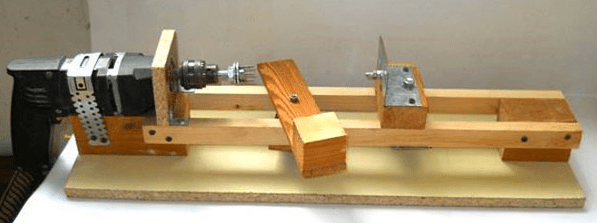

You can make a drilling machine from an electric drill with your own hands. Such a machine consists of a bed, a vertical stand, a rotation mechanism and a feeder. Despite the simplicity of the design, the machine significantly increases the accuracy of processing parts.

Video: do-it-yourself drilling machine from a drill

Among the numerous attachments for electric drills produced by industry, there are also such “exotic” specimens as a pump attachment for pumping liquids or a special attachment for plucking poultry feathers. IN Everyday life they are not as often in demand as carpentry and locksmith tool, which is used in almost every home.

An electric drill can save you money and energy. For home and occasional work, you do not need to buy several professional machines. Special attachments will make the tool universal: drilling and cutting, grinding and turning, kneading and chiseling - this is not a complete list of operations available for the drill. To make work a joy, you must follow safety rules

A hand drill is a trouble-free drilling tool, which enjoyed enormous popularity half a century ago. As soon as electric drills appeared, demand hand-held devices decreased, but did not disappear completely. Today, this tool is probably gathering dust in the garage, and everyone wonders what can be done with an old hand drill. You can try to sell the instrument, but do not rush, you will be able to get no more than 100 rubles for this instrument, but after making useful homemade products, you will get a unique unit. Let us consider in detail what can be made from the tool in question.

Interesting facts about hand drill

Since its invention, the tool in question has been actively used for drilling wooden and metal structures, and such a device is not intended for drilling concrete. This is due to the fact that the device does not have a shock function, so it is almost impossible to drill a hole in concrete with such a tool. However, home craftsmen found a way out of the situation. While drilling concrete, periodic hammer blows were applied to the heel, which allowed the drill to advance into the material.

The main drawback of the tool is known to everyone who has ever used it. It involves the need for physical effort. If drilling wood required little effort, when working with metal and concrete, it took at least several hours to achieve results.

This is interesting!The advantage that remains with the hand drill even today is the autonomy of the tool. It does not require an electrical connection and does not have removable batteries. That is why, when going to the country or when working in field conditions, don't forget to take a hand drill with you.

The operating principle of the tool in question is simple, and consists of transmitting rotational manipulations from the handle to the tool chuck through a pair of gear drives. Gears help increase the rotation speed of the chuck, but at the same time reduce the torque. The simple and uncomplicated design makes the tool in question not only repairable, but also durable. All that is needed to extend the service life is to monitor the amount of lubricant on the gears of the tool.

So, if you remember the design of the hand drill mechanism, as well as what it is, then it’s time to figure out what can be made from this tool.

Device for tightening and unscrewing long screws

To unscrew or screw a long self-tapping screw into wood, you will need to put in a lot of effort. If you tried to do this with a screwdriver or electric drill, then you know that doing this is quite difficult. The self-tapping screw will “go” into the wood to a certain depth, but it is almost impossible to tighten it completely with electric tools. It is also extremely difficult to do this manually, so you should call an old hand drill for help.

The tool for screwing or unscrewing long screws does not need to be modified. You just need to press collet chuck device of the appropriate size bit, and get down to business. The efficiency of using hand tools when screwing long self-tapping screws is an order of magnitude higher compared to low-power screwdrivers and high-speed electric drills.

Making a screwdriver attachment from a hand drill

Few people know what can be done from old drill, so don't be in a rush to dispose of or sell this invaluable tool. From it you can make a device for a screwdriver, which is designed for screwing and unscrewing various fasteners. These can be not only long self-tapping screws, but also bolts and nuts. The secret of this device is that you can very easily make it out of an old drill. useful thing, which will allow you to get to hard to reach places followed by unscrewing the fasteners.

The principle of making an attachment or device for a screwdriver from a hand drill is to perform the following manipulations:

- First, we free the tool from unnecessary parts. To do this, remove the chuck from the tool, as well as the handle.

- The thrust heel is also dismantled, which will not be needed in the new device.

- The shaft on which the cartridge was located has a fairly large diameter. It will not be possible to install a shaft of this diameter into a screwdriver chuck, so let’s start grinding it down

- It is recommended to grind the shaft to reduce its diameter at lathe. The use of an emery wheel or grinder for such purposes is not recommended, since the grinding will be uneven

- To grind a shaft on a lathe, it will first need to be removed from the tool. It's not difficult to do this. In the mechanism, near the bevel gear, which is mounted on the shaft, there is a hole with a cotter pin. This cotter pin must be knocked out, thereby disconnecting the gear from the shaft

- After grinding the shaft down to 8-10 mm on a lathe, it should be installed in place, not forgetting to pin it. The shaft is made of hardened steel, so before grinding it, it is recommended to do heat treatment (heat it with a blowtorch)

- The shaft is driven by a ball bearing, which can be lubricated to extend its life.

- The first part of the work is completed. The shaft that was ground off will be used as a transmission device on the new device. The working element on the device will be the shaft on which the handle is attached

- The second shaft has a specific hexagonal shape, which should also be machined so that socket heads or other attachments can be put on it. The simplest option is to make a square one from the hexagonal shape of the end protrusion for securing the heads

- This can be done using a grinder and a cutting wheel. In this case, only heads for screwing and unscrewing bolted connections can be installed on such a shaft

- If you plan to use the device for other purposes, then you can cut threads on the shaft by first making it cylindrical and trimmed to the required size

- A drill chuck must be screwed onto the cut thread, into which you can install various attachments - bits, mixers, drills, cutters, etc.

- Please also note that to install the cartridge on the secondary shaft of the device, you will also need to cut internal thread for checking clamping of the collet chuck

- To complete the manufacture of the device from an old hand drill, it is necessary to cut off the remaining part on which the thrust foot was attached

- After this, the homemade device is ready for use. All that remains is to fix it in the screwdriver chuck and test it

The advantage of such a device is that it increases the torque. The screwdriver drives a small diameter gear, which transmits force to the larger gear. A small gear is attached to the large gear, and the force is transmitted to the second large gear, on which the secondary shaft is located, thereby reducing the rotation speed, which means increasing the torque. As a result, the device allows you to unscrew and tear off stuck and rusted bolted connections. However, do not forget that the main role is played by the screwdriver, which must have the necessary power reserve, otherwise its engine may suffer.

What are the advantages of using an old drill attachment for a screwdriver?

Having figured out what can be done from an outdated hand drill, you need to find out the advantages of this device. These advantages include:

- Torque increases 6-7 times. This means that the force from the screwdriver increases by so many times

- Ability to access bolts and nuts that are in hard-to-reach places

- To make the device, you will not need additional materials, since everything can be done with your own hands.

- No need to repurchase Consumables

In addition to the fact that the device can be used for screwing and unscrewing fasteners and large screws, the device also allows you to quickly tighten and unscrew them. You will definitely be satisfied with this device. How to make it is shown in detail in the video instructions below.

What else can be made from an old hand drill - quick-driver

The above describes the process of making a homemade product from an old two-speed drill, which has 4 gears. However, there are also single-speed devices that can also be used to make homemade products. This type of tool can be used to make a screwdriver that can be operated with one hand. This is very convenient when the other hand is busy. This device is called a quick-twist, and the principle of its manufacture is as follows:

- Take an old clamp or weld a U-shaped frame on which the component parts homemade products

- On one side, weld a fixed handle, as well as a movable trigger (made of steel with a thickness of at least 1.5 mm), which is connected to ¼-1/5 of the bevel gear from the tool

- On the other side of the U-shaped frame, a shaft is attached, on which a cartridge and a bevel gear are fixed, connected to the half-gear from the trigger

- When you press the handle, the cartridge moves due to the transmission of torque

- A bit of the appropriate type is fixed into the chuck, after which you can start working

This homemade product has one drawback - it is necessary to disconnect the bit from the fastening element in order to return the handle to its original position. An example of such an invention is shown in the photo below.

Making a machine for winding coils from a drill

What else can be made from an old hand drill that has been gathering dust in the garage for more than 10 years? Of course, you can make a simple device that will allow you to wind coils. You can wind not only threads and ropes, but also wire, for example, when rewinding electric motors.

The design of such a machine is very simple, and to manufacture it you will need to use the following devices:

- Vice - a fixed handle or tool stop located in a horizontal position is attached to them

- A block of wood of the appropriate size, which is located near the cartridge. This block acts as a stop, holding the tool in a horizontal position

- A reel or other devices are attached to the tool chuck, onto which material is wound - wire, rope, threads, etc.

A photo of such a device is shown in the photo below. If you attach a sharpening wheel to the chuck, the tool can be used as a hand sharpener.

Drilling machine from hand drill

To prevent the old drill from sitting on a shelf in the garage, it is proposed to make a manual drilling machine from it. The advantage of such a tool is that you can always carefully make a hole in wood, glass, plastic, metal and even ceramic tiles, using the appropriate types of drills. The manufacturing principle is simple, and lies in the fact that you first need to make a frame with a movable frame on which to install hand tool.

- For manufacturing you will need a board, metal corners and cylindrical guides, for example, studs, on which you need to grind off the threads. The length of the pins affects the amount of tool movement

- First, a base is made to which pins are attached, located straight on one side of the wooden frame

- Holes are drilled in the corners for the studs

- These corners with holes are put on studs

- A wooden board of the appropriate size is attached to the corners, which will serve as the basis for securing the tool

- The drill is installed and secured to the moving part

- To ensure smooth movement of the bed, a latch is made that acts on the pin, thereby limiting the movement of the movable bed

The design of the device can be different, and it all depends on your own ingenuity, but the principle of creating such an invention with your own hands is shown in the photo below.

Making a ratchet from an old hand drill

The range of tool capabilities does not end there. You can also make a convenient ratchet wrench from an old and unnecessary hand drill. Moreover, it can be used as a regular wrench, that is, tightened by hand, or in tandem with a screwdriver.

To make the tool you will need two bevel gears and a drill shaft, as well as steel tubes, plates and welding machine. The process of making the tool is shown in detail in the video material. The result is a universal hand tool that is definitely stronger than modern ratchet wrenches.

As you can see, a hand drill is a very interesting tool from which you can make various homemade products, expanding your capabilities and also simplifying your work. If you come up with something else that can be done with a hand drill, be sure to share it, as it will help people use an outdated tool to do new things.

", and serious things related to needlework can be a little complicated 🙂, then today we have an easy article called "" - where we will talk about how you can use such the right tool not only for its intended purpose.

Unconventional use of a drill in no way implies a violation of the rules from the article “Safety precautions during repairs”. That is, in this article we do not encourage you to use a drill as a drilling machine, grinding machine or lathe. Most of today's tips could be classified in the "Recipes" section - if adapting a drill did not imply some - absolutely minimal - needlework. Well, plus other methods that have nothing to do with recipes - but also...

And the first way to use a drill in a non-traditional way is to use a drill as a mixer.

The idea is very simple: instead of a drill, a mixer stirrer is inserted. And then everything is as usual: mix the mixer, turn on the drill - and go!

But it happens that there is no stirrer from the mixer. And you need a mixer. Then, instead of a mixer, you can use a regular whisk to beat eggs:

Of course, a situation is possible when the whisk is also unavailable. In this case, a fork will help!

However, it happens that there is no fork at hand. But you still need a mixer. In this case, ordinary scissors will help you! Just insert them instead of a drill - and the mixer is ready. Scissors can be inserted like this:

And the scissors can be inserted like this:

In general, the use of a drill as a mixer can be seen in the video:

Here's a good, unconventional way to use a drill. However, a problem that can arise is that splashes of what is being whipped get on the drill and your hands - and this can be unpleasant. In this case, you can use splash protection like this:

The next non-traditional use for a drill is a “pencil sharpener.”

Do you ever end up with a lot of pencils that need sharpening? It’s unlikely 🙂 But if anything, this method of unconventional use of a drill is for you.

It's very simple - instead of a drill, a pencil sharpener is inserted into the drill. The trick is to make the pencil hole rotate coaxially with the drill so you can sharpen as many pencils as you want in one sitting. This method is also good if you need to sharpen a lot of aspen stakes :)

Electric meat grinder from a drill

You can use a drill to make an electric meat grinder. To do this, we disassemble the meat grinder and take out the shaft:

We insert a metal bolt without a head into the shaft or directly into the drill. This results in an electric meat grinder:

Works great and grinds minced meat:

To prove this, here is a video about the operation of an electric meat grinder:

vyFqgKqrZVM

As you can see, everything is simple!

The following are just a few unconventional ways to use a drill.

A drill can be used to rewind threads. To rewind thread from a large spool to a small spool, you will need a drill. Secure the drill. Use a drill or long screw to attach the coils.

Using a drill, you can twist wire (or weave ropes):

And finally, the drill can be used as an ice cream licking device:

As you can see, there are many options for how to use a drill in an unconventional way.

Sometimes there is a need to cut a fairly hard board into several planks. You can’t do this kind of work manually, but buy a factory one circular saw for the sake of a single case it is unprofitable. There is a very simple solution - it is done small size circular from conventional drill.

It is better to make the machine small in size so that it can be put away on a shelf when its presence is no longer needed. Its design is extremely simple:

- base made of a thick board or piece of chipboard;

- working surface;

- racks;

- shaft with circular saw;

- electric drive in the form of a drill.

We make the base from a sheet Chipboard thickness 30 mm, it is enough to cut a piece measuring 300x250 mm. For desktop We choose a sheet of duralumin 4 mm thick - it is quite rigid and light, so as not to weigh down the entire structure. We make a hole in the right place for circular saw measuring approximately 160x10 mm.

The holder for the drill itself can be made independently - all the necessary dimensions and drawings are available on the Internet, but a similar design for the shaft with a saw can be purchased in a store or at a clothing market. The bearing for the shaft must be selected dustproof- when the homemade machine is working, there will be a lot of small waste in the form of wood dust.

A circular saw from a drill is assembled according to the standard scheme: first, all parts are fixed to the base, then the work table is mounted and the drill is connected.

Security measures

When working on any machine, you must strictly follow the following rules:

- the place of upcoming work must be cleared of unnecessary materials and tools;

- workpieces are fed smoothly without jerking or distortion, so that the cutting tool does not jam;

- the plane of rotation of the circular saw must be limited from above by a special protective casing;

- the machine must be kept clean and put away after each use;

- If the mini sawmill is not used for a long time, then lubricate all metal parts with machine oil.

This small machine can cut not only wooden boards. If you install special cutters on it, you can process parts made of brass and other non-ferrous metals, plastic or propylene.

Other homemade machines

Many users are interested in what else can be done using improvised tools from a drill with their own hands? There are many answers - home craftsmen are already making various homemade products from drills in garage workshops. Drill - universal tool, therefore, with a certain skill and imagination, you can make whatever your heart desires.

- Sharpener, you just need to buy emery in the form of a circle and make a special holder in which the drill is attached.

- Drillingmachine- there are special holders for vertical drilling or stands.

- Turningmachine small size for wood processing.

- Mini drill for various needs home handyman.

- To mow the grass around your garden plot without any problems, you can do it yourself drill trimmer.

- Grinder from a drill It’s done quickly, just buy specific attachments.

- Garage car repair technicians install original winches to replace engines based on old, very powerful tools.

- Gardeners make holes for planting young trees using homemade drill bit.

- When pouring the foundation for utility room in the private sector, some users use homemade vibrator, made from a drill to quickly compact a concrete structure.

Original devices

You can continue the list of homemade products ad infinitum, but we’d better tell you in more detail about some homemade machines, which can be made from any drill model.

A drill made from a drill is not a fantasy, but a real and fairly universal machine, assembled independently. The main thing is that you need to order from Chinese engineers (if you couldn’t find it in your city) flexible shaft from a standard medical unit. As a result, a drill appears in your arsenal, which can be used for engraving work or drill holes using special burs in small parts or structures that cannot be reached with a standard drill.

A woodworking or lathe for home can easily be made using a drill. The tool must be secured with special clamps quite rigidly and inserted into a chuck of a special design holder with several sharp pins that keep the workpiece from turning. The center of the rear holder (headstock) and the clamp at the front of a homemade lathe should be located on the same axis. Precision is necessary to prevent runout as the workpiece rotates. After installing the part, tailstock It is firmly fixed with a special clamp.

The third element of the machine is handyman in the form of a wooden block on which a chisel or other tool for processing the workpiece will rest.

Important! When working on a lathe, do not forget about safety, be sure to wear safety glasses, and the sleeves of clothing should fit tightly around your forearms.

Turning a machine for processing wooden workpieces will work properly if the drill has a built-in electronic speed controller. By trial method you establish optimal mode rotation for efficient wood processing. Using such a woodworking device, you can make unique products for household needs: for example, a rolling pin or pestle with a mortar, a candlestick or a prefabricated candelabra.

Winch

An original winch based on an old one, but powerful drill will become an indispensable assistant on the farm, especially for those users who live in own home and there is personal plot. Simple situation: in summer shower you decide to install a larger container, but raising it to such a height alone is problematic. Using a winch, this can be done in a few minutes. You just need to first calculate the weight of the container and the spindle speed.

According to garage craftsmen, homemade winch easily lifts the engine from passenger car. Watch the video if you don't take my word for it:

Experts advise using homemade device, setting the drill to the most minimum speed. This design can move objects with different masses, because craftsmen even make winches based on an ordinary car starter.

The relevance of the question of how to make a router from a drill with your own hands is explained by the fact that not all home craftsmen can afford to purchase expensive serial models. Meanwhile, the usefulness of such a device and the need for its use in many situations (construction and repair work, production of all kinds of wood structures, decorative design products made from various materials) are undeniable.

Using a router equipped with an appropriate working tool, you can successfully mill wood products, form edges of various configurations on them, and prepare seats For door locks and loops, create on wooden parts grooves, as well as solve many other technological problems.

Components and assembly algorithm

It is possible to make a milling machine, which almost every home craftsman has, but it should be borne in mind that such a device cannot fully replace the serial model. This is explained by the fact that the chuck of a conventional hand drill is capable of rotating at a speed of 3000 rpm, while a serial milling cutter is able to ensure rotation of the tool used at a speed of up to 30,000 rpm. In addition, the gearbox of a household electric drill is not designed for intense loads, which will quickly cause it to fail.

Vertical router from a drill

Meanwhile, the simplest milling cutter, made from scrap materials at minimal financial cost, is capable of successfully coping with many technological tasks. To make your own milling machine from an electric drill, you should find following materials and tools:

- several pieces of chipboard or thick plywood;

- a clamp with which the drill will be fixed to the base of the device;

- bolts, screws and other fasteners;

- feather drill or drill bit with a diameter of 40 mm;

- standard set of locksmith tools.

The assembly process itself homemade router goes through the following algorithm.

- From chipboard sheets or plywood, the base of the future router is assembled, which includes a horizontal base and a vertical part on which the electric drill will be fixed. The dimensions of the sheets of chipboard or plywood from which such a structure will be made are calculated depending on the dimensions of the electric drill used as the basis of the homemade machine.

- A hole with a diameter of 40 mm is drilled in the horizontal base of the device, which is necessary to provide access for the tool to the processing area.

- On vertical rack device, a clamp is attached using a bolt, in which the electric drill is fixed. The drill should be positioned in such a way that the lower end of its chuck is a few millimeters from the horizontal base of the router.

- To make the position of the drill on a vertical stand more stable, you can fix a small wooden block, which will act as a stop.

Adjusting the depth of cut when using such a router is carried out by changing the position of the electric drill in the clamp that secures it.

How to make a milling machine of the design described above more convenient and functional? To do this, it can be equipped with a simple microlift, which will be responsible for moving the electric drill in the vertical direction. To make such an elevator you will need the following consumables and components:

- two metal rods that will act as guide elements;

- a platform (carriage) for fixing an electric drill, made of chipboard or thick plywood;

- a threaded axis and a nut, which will be responsible for moving the electric drill in the vertical direction;

- elements that ensure the fixation of the electric drill in the required position.

The principle by which such a homemade router works is quite simple and is as follows.

- When the threaded axis rotates, the carriage with the drill attached to it moves in the vertical direction.

- After the electric drill and the tool secured in its chuck are set in the required position, the carriage is fixed using fasteners.

Naturally, the entire design of such a homemade router, the operation of which is well demonstrated in the video, must be fixed on a reliable basis. The latter can be the surface of a desktop or workbench.

Machine made from an old electric motor

With the help of which many technological operations are quite successfully performed, it can be manufactured without the use of an electric drill. In order to make such a device, you will need the following consumables and components.