Special conditions exploitation bath room require the correct construction of enclosing structures and their layers. Then the time to warm up the bath, fuel consumption and heat retention will be optimal for creating favorable conditions allowing a person to carry out bath procedures. We will tell you how to insulate the ceiling in the bath. The heated air rises, so insufficient insulation of the ceiling structure contributes to the rapid leakage of a third of the heat from the steam room.

Functions of insulation for the ceiling in the bath

Insulation of the ceiling in the bath performs certain functions. Moreover, the higher the air temperature in the bath room, the higher the requirements for the quality of thermal insulation of the ceiling surface.

Thermal insulation of the bath ceiling is designed to solve the following tasks:

- The heated air escapes quickly through cracks in the ceiling. High-quality insulation should ensure the tightness of the structure.

- Heat is lost even if building construction have high thermal conductivity. Thermal insulation material will not allow such elements to come into contact with heated air.

- Heat waves easily cross barriers with a uniform texture, so the use of loose porous insulation will protect against heat loss.

If the heat-insulating material is laid in the multilayer structure of the bath floor, then it reliably protects against all three types of heat loss. At the same time, it is important to correctly calculate the thickness of the insulation, use the appropriate material, and lay it in the right place in the bath floor. Violation of the principles of laying thermal insulation will lead to condensation on the ceiling surface, prolonged heating of the room and high fuel consumption.

Scheme of the device of the insulated ceiling

Before you make the ceiling in the bath, you need to understand the features of the insulated floor device. In baths made of any materials, the floor structure remains unchanged. The functions of the supporting frame are performed by beams that rest on the top of the walls made of timber or logs, or on the Mauerlat in buildings made of brick or wall panels. The beam is treated with an antiseptic without fail. It is also necessary to additionally protect the beams when they come into contact with brick, concrete or metal surfaces. In this place, the bearing elements are wrapped with roofing felt in two layers.

The ceiling in the steam room can be made according to one of the following schemes:

- from the side of the room, the ceiling surface must be sheathed with boards that are attached directly to the floor beams (this option is suitable for plastering, but you can mount the boards in a run-up);

- cranial bars are attached to the lower part of the side face of the floor beams on both sides, from above between load-bearing elements boards are laid on them;

- so that the surface of the ceiling is in the same plane with the beams, cuts are made in the boards along the height of the cranial bars (it is important that the height of the board is twice the thickness of the beam);

- another version of the ceiling scheme is the installation of cranial bars and roll boards above them, diaphragm boards are attached to the bars, and the ceiling is hemmed with an ordinary board from below to the beams.

Important! If in any of the above proposed schemes the material for insulation is mineral wool or expanded clay, then laying waterproofing is mandatory. This layer is laid above the insulation and protects against the collection of condensate from the attic.

Also, when choosing the option with laying boards, it is worth remembering that a gap of 25 mm is left between them and the floor beams on each side. It is needed to protect against deformation due to the expansion of the material under conditions of temperature and humidity changes. In places where the chimney passes through wooden structures overlaps make a gap of 250 mm.

In any scheme of the device, a layer of vapor barrier is laid on top of the filing boards or reel. The material must go around all the beams. It is laid with an overlap of the strips and subsequent gluing of the joints with adhesive tape. After that, a heat insulator is laid in the voids between the supporting elements. Its height should correspond to the thickness of the beam. A layer of waterproofing is laid above and the subfloor of the attic is mounted.

Instead of boards for the ceiling device, fiberboard, cement-bonded particle boards are used. At the junction with the chimney, all wooden structures are treated with flame retardants and protected from fire with asbestos sheets.

Warming methods and their advantages

Depending on the type of bath roof, one of two options for insulating the room is used - laying heat insulating material from the outside or inside of the ceiling.

External insulation

Ceiling insulation in the bath cold roof carried out from the outside of the structure. This option is simple and reliable and is used if the bath has an attic and a pitched roof. From below, the ceiling is hemmed with boards, a beam simulator or clapboard, above a vapor barrier is laid between the beams (for example, a polyethylene film or aluminum foil), and then a heater follows.

Mineral wool, expanded clay or insulating material with a glued layer of vapor barrier are suitable for insulation from the outside. A layer of waterproofing is spread above and the attic floor is mounted.

Internal insulation

If there is no attic above, then the insulation for the bath is attached to the ceiling from the inside. This insulation option is more difficult to perform, but in the absence of an attic, there is no choice left. Efficiency internal insulation much lower, because the race point in the floor structure is shifted towards the room, which means that the thermal conductivity increases, and the steam room will lose heat faster.

With this method of the device, a layer of waterproofing is first attached to the ceiling surface from the boards. It is overlapped, and the joints are glued. Staples are used for fixation. Then thermal insulation is attached to the ceiling surface. If foam is used, then fungal dowels are suitable for fixing. Minvata and others soft insulation laid between the guides wooden crate, which is built on the ceiling in advance. After laying the thermal insulation, a layer of vapor barrier material and a lining of boards or other material suitable for a bath are mounted.

The choice of material for insulation and installation technology

For the bath room, thermal insulation is selected, which, when heated, does not form toxic compounds and can be operated in conditions of high humidity and extreme temperatures. Choose lightweight materials that are easy to transport and install.

Important! The heat insulator must have a certain degree of fire resistance and not support combustion.

After choosing the right material step by step guide on the insulation of the ceiling in the bath with your own hands will help you install the insulation correctly.

Mineral wool

This insulator is often used for warming private houses and baths. This fibrous thermal insulation is available in three versions:

- stone wool;

- slag;

- glass wool.

The main advantage of mineral wool is low thermal conductivity, resistance to damage by rodents, insects and mold, low weight. The material does not support combustion and does not change its characteristics with temperature changes. Mineral wool is sold in the form of slabs and rolls.

Important! The main disadvantage of mineral wool is its high hygroscopicity. But this problem is solved by a competent device for vapor and waterproofing. The material should not come into contact with the air flow coming from the bath room.

Mounting sequence mineral wool:

- After the construction of the roll of boards and cranial bars, a layer of vapor barrier is spread between the floor beams.

- Slabs of material are cut to a width slightly larger than the spacing of the beams to ensure a snug fit to building structures. The material is placed in the gaps between the beams. To achieve the desired height, the mineral wool is laid in several layers so that the joints of the plates in the layers do not coincide.

- A layer of waterproofing is spread above.

Clay insulation

From ancient times, clay was used to insulate the ceiling surface in the bath. A three-centimeter layer of this material copes well with the task of warming the room and performs the functions of a vapor barrier.

The advantages of clay include its environmental friendliness, reasonable price. However, the thermal conductivity of this material is somewhat lower than that of mineral wool or expanded clay. The process of laying clay for thermal insulation of the ceiling surface is quite laborious. In addition, the resulting cracks will subsequently have to be sealed.

To reduce the weight of clay insulation, well-dried sawdust is added to it. Clay can also be mixed with sand, lime or cement. By itself, the clay layer is ineffective. A layer of oak leaves or sawdust is laid above it, and an earthen layer 180 mm high follows.

Expanded clay insulation

These small porous clay pebbles are ideal for warming a bath because they have the following advantages:

- do not allocate harmful substances;

- it is a natural environmentally friendly material;

- do not support combustion;

- have durability;

- not subject to damage by rot and mold;

- acceptable price;

- ease of installation.

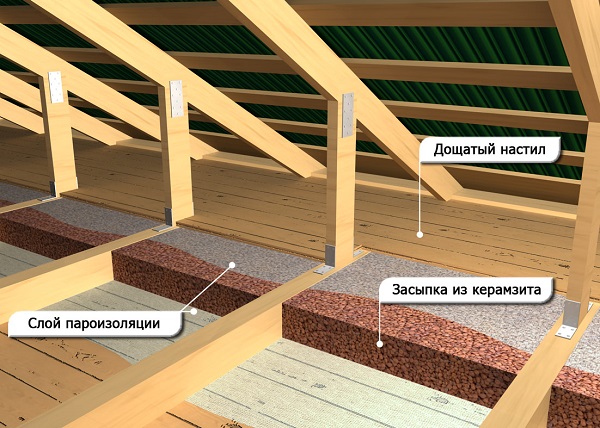

Expanded clay does not absorb moisture as much as mineral wool, but you should not refuse to lay steam and waterproofing. The installation sequence is the same as for mineral wool. The granules fall asleep between the beams along the laid vapor barrier. The height of the backfill should be equal to the height of the beams. The waterproofing is on top.

The working conditions of baths (especially steam rooms) are not similar to the usual modes of operation of residential premises. The parameters of the microclimate of high-temperature spa areas are important not only for creating comfort, but also for extending the life of the buildings themselves. In addition, the problem of energy saving is becoming more and more urgent every year. “What is the best way to insulate the ceiling in the bath?” - this issue is given Special attention, since the heat loss from the ascending streams of heated air and steam can be up to 30% - 35% of the heat exchange of the steam room.

In addition to the fact that it is necessary to significantly reduce energy losses, it is required to reach certain parameters for vapor barrier. At the same time, we must not forget about the special requirements for the safety and environmental friendliness of all materials used. When choosing the design of the ceiling lathing for the bath, the types of strength elements, membranes and insulation, one should proceed from the observance of three basic principles:

- fast kindling;

- slow cooling (comfort and heat saving);

- a special microclimate characterized by the accumulation of steam (it is required to avoid its condensation).

The classic approach to arranging the ceiling in the steam room provides for sewing the draft plane (adjacent to the load-bearing beams) with wide thick boards - the “magpie”. A thickness of 50 mm is considered excessive. From the experience of application it is known that such a flooring begins to accumulate moisture, which does not have time to evaporate between steam sessions. As a result, the likelihood of getting a ceiling prone to condensation increases.

When equipping a room with a classic crate from the "magpie", the ceiling of the bath is most often insulated with mineral wool, expanded clay or other proven heaters from above - from the side of the roof.

The modern trend is associated with the use of two types of insulation, one of which is reflective, and the second plays the role of the main one. The better to insulate the ceiling of the bath in order to implement the functions of infrared reflection and thermal break - will be discussed in the following sections of the article.

The role of foil materials and vapor barrier films

Ideal heaters for baths do not exist. It is not possible to equally realize the reflection of heat rays, resistance to heat transfer and vapor barrier with one material. Aluminium foil and foil sandwiches such as folgoizol allow you to select the optimal combination of materials for equipping baths of any design.

For example, folgoizol makes possible mounting non-hygroscopic mineral wool, as it is an ideal vapor barrier.

The reflective layer is located immediately behind the decorative ceiling lining. If the main heat-shielding layer is further placed, then an air gap of at least 2–3 cm must be provided between it and the reflector.

It is advisable to limit the use of polyethylene films to waterproofing in under-roof areas. Vapor barrier without the formation of condensate is much better provided by foil sandwiches and membrane materials with special microvilli.

Ceiling insulation with mineral wool

Mineral (aka basalt) wool is more often than other materials used as the main insulating layer. For many specialists involved in the construction of baths, the question of "how to insulate the ceiling in the bath" has long been resolved in its favor. Main advantage stone wool over all other insulating materials - high heat resistance and fire safety. Unlike glass wool, the structure of fibers based on molten basalt is not harmful to the respiratory system. However, the insulation of the ceiling in the mineral wool bath has serious limitations. This is a high hygroscopicity of the material and the presence of hydrophobic impregnations designed to resist the penetration of moisture. Impregnations are made on the basis of waxy low-melting compounds, which are prone to unwanted gas emission when heated above 70 °C - 80 °C.

Ceiling insulated with mineral wool

Not every mineral wool is suitable for arranging baths. Use only brands without impregnations with a direct indication of the intended use in spa areas: for example, "ISOVER Sauna" or "ROCKWOOL Sauna Butts". The first material is roll type, the second is made in the form of plates. Both are lined on one side with a vapor barrier based on aluminum foil. The ceiling of the bath should be insulated with mineral wool while providing double-sided hydro- and / or vapor barrier. When mounting foil or other types of protective layers, it is necessary to leave an air heat-insulating gap between the wool and the membrane.

Use of Styrofoam

In a number of sources, one can find statements about the inadmissibility of using foam plastics (PPS) and extruded polystyrene foam (EPS) for bath and sauna equipment due to the release of harmful substances by these materials when heated. Others argue that the thermal degradation of this insulation begins at 160 ° C, and the subceiling space of the Russian bath can only warm up to 100 ° C - 110 ° C. And therefore, they say, restrictions on lining the steam room with foam plastic or EPS do not make sense.

Let's dot the "and" in this matter. The fact is that neither the first nor the second position is fully justified. Surface emission of styrene can begin even before thermal degradation (in the range of 90 °C - 130 °C).

Therefore, the material cannot be used as an inner layer of insulation that is in direct contact with the decorative lining of the ceiling in the steam room. But under the condition of using reflective two- and three-layer foil materials, it is quite possible to place a heat-shielding layer of PPS or XPS behind them, since the temperature on the back surface of the sandwich does not exceed 50 ° C.

Expanded polystyrene for the bath ceiling is possible only with a reflective multi-layer screen

It is advisable to use expanded polystyrenes to insulate the ceiling in the bath with your own hands, working alone. It is especially convenient to use XPS boards, if necessary, to mount a layer of insulation on the lower surface of the draft ceiling. Without assistants, it is extremely difficult to carry out such work with loose materials such as mineral wool.

Expanded clay

Ceiling insulation with expanded clay is used in baths with under-roof rooms (attics, attics). The properties of expanded clay are in many ways similar to those of mineral wool. The same pluses: environmental friendliness, resistance to high temperatures ... and the same minus: the material absorbs moisture too well. From below, it must be protected from the penetration of steam, and from above - from the effects of atmospheric and condensation moisture.

In addition, the fired pellets of this heat insulator have a much lower resistance to heat transfer than mineral wool. For this reason, the required effective embankment thickness is at least 30 cm.

The option is suitable for steam rooms of a large area. Since over the spacious premises the floor beams have a significant vertical section, deep natural niches for backfilling are formed. required amount expanded clay.

Self-growing foam concrete and other DIY insulation

Insulating the ceiling with clay with sawdust, homemade cellular concrete, moss and other exotic materials is advisable if you have access to these relatively cheap or free thermal insulators.

If during the construction process you have an excess of basic draft materials (for example, cement), then some of them can be used to equip a heat-insulated ceiling in a steam room. The technology of self-growing aerated concrete is based on the interaction of three main components: cement, water and a special gas-forming powder. In addition to the listed materials, density-reducing components such as sawdust and straw can be added to the mixture.

The main advantages of the technology in comparison with expanded clay backfills are lower thermal conductivity and greater moisture resistance. The resulting cellular material is enough to fill with a layer of 10 - 12 cm. Expansion under the influence of gas-forming additives, in addition to heat-saving properties, helps to obtain a continuous surface without cracks and gaps. In addition, waterproofing is not required with this option.

If you have your carpentry, and the under-roofing zone of the bath allows backfilling in large layers, it is possible to realize the insulation of the ceiling with sawdust, combining them with sand, clay and some other building and natural materials. Clay has good steam and waterproofing qualities. Therefore, before backfilling sawdust, first a clay layer is made about 2 cm thick. Then sawdust is backfilled with a layer of about 10-15 cm in height. Sand, dry earth or moss is laid on top of the sawdust, mixed with needles with a layer of about 15 cm. Mixtures of sawdust with clay are also used as masses that have both heat-saving and waterproofing properties.

Any bath needs high-quality insulation of the ceiling - warm air, according to the laws of physics, tends to rise up. And if there is no heat-insulating layer on its way, then significantly more fuel will be needed to heat the bath and maintain a consistently high temperature in it.

But that's not the only problem - in the absence of insulation on the ceiling of the bath, condensation will accumulate, and drops dripping from above on the head and back are unlikely to bring great pleasure to anyone. And the moisture going up along with the heat will contribute to the destruction of the ceilings and the roof support system. The only way to avoid these troubles is to make high-quality ceiling insulation in a bath with a cold roof. And our material will tell you what and how to do it.

We plan work

Before you buy materials and take on tools, you should carefully plan your actions. A clearer understanding of the matter will save you from annoying mistakes and the need to redo everything in the future.

The first question is whether it is possible to insulate the ceiling in the bath on your own.? Or is it worth entrusting this business to a team of builders? The process of insulating the ceiling itself is not something complicated, therefore it is not difficult to perform it on your own, even without much experience in repair and construction. The main thing is to carefully observe the technology and approach the matter responsibly. In favor self-insulation ceiling also says accessibility the right materials– they can be found in any large hardware store or in the market.

The second question is what, in fact, needs to be done? Ceiling insulation in cold bath consists of three stages:

- vapor barrier;

- thermal insulation;

- waterproofing.

The result should be a kind of “layer cake”, the bottom layer of which is ceiling covering, and above it, vapor barrier, thermal insulation and waterproofing are located sequentially from bottom to top. More details about why this is necessary and how to do it will be described below. Now it's time to think about the choice of materials.

We select a heater

The melted bath maintains a very high temperature and humidity. The heat-insulating material must meet these conditions and, most importantly, not emit harmful substances when heated. In addition, a good heater for a bath should be fire resistant. It is undesirable that the thermal insulation material be too heavy or inconvenient to carry and install. Now consider the materials in more detail.

It is the most common type of insulation for baths and private houses; This is a fibrous heat-insulating material that exists in three types:

- glass wool;

- stone wool, which is made from basalt or other molten rocks;

- cinder wool, made, like cinder blocks, from blast-furnace slags.

The main advantage of mineral wool, in addition to its very low thermal conductivity, is that it is not a breeding ground for fungi, mold, insects or rodents. For a bath located on a private plot, this is especially important. It is also worth noting that this material does not burn, does not change its volume and shape when heated or cooled, and is very easy to install due to its low weight. Mineral wool is produced in the form of rectangular panels or in the form of rolls.

As for the disadvantages, there are two of them - the ability of mineral wool to absorb moisture (especially slag wool) and the potential harm of the phenols contained in them. Both of these shortcomings can be eliminated if you correctly approach the issue of vapor and waterproofing and prevent contact of mineral wool with the air flow, especially inside the bath.

Important! Small particles of mineral wool can have a damaging effect on the eyes, skin or lungs of a person, therefore, when working with it, be sure to wear tight clothing and use gloves, goggles and a respirator.

Table. comparative characteristics various types of mineral wool.

Expanded clay

It is a small pebbles of clay with a porous structure. In terms of its advantages, expanded clay is the most suitable material to insulate the ceiling in the bath.

- Safety- it does not burn, is environmentally friendly and does not emit harmful substances into the air.

- Durability- expanded clay does not decompose under the action sun rays and does not break down over time.

- This material not an attractive environment for fungus or bacteria.

- Has a low cost and is easy to install.

Also, expanded clay absorbs significantly less moisture than mineral wool, but at the same time, the need for vapor barrier and waterproofing layers still remains.

Expanded clay

Styrofoam

At one time he was one of the leaders among thermal insulation materials. But even taking into account all its advantages, you should not choose polystyrene foam as a ceiling insulation in a bath - in case of fire, the material burns well, and its smoke is very dangerous for human life and health. It is also able to decompose simply under the influence of high temperatures (and they are inevitable in the bath), therefore, polystyrene foam can hardly be called smart choice in this case.

Styrofoam

Ecowool

A natural fibrous material made from cellulose with additives that make it flame resistant and repel rodents, insects and micro-organisms. Ecowool has a low weight and the ability to fill all the cracks and gaps. Like expanded clay, it is environmentally friendly and does not emit any substances harmful to humans into the air.

However, ecowool is able to absorb a lot of moisture, which worsens its thermal insulation properties. Therefore, when using it, it is desirable good ventilation under the roof and high-quality waterproofing. Another disadvantage of its use is the complexity of installation - with the "wet" method of application, special equipment is required.

"Wet" method of applying ecowool

A mixture of cement and sawdust

It is a "classic" material for insulation, which was used even before the appearance of mineral wool or polystyrene on the market. In some cases, clay can be used instead of cement, and straw instead of sawdust.

First, a dry mixture is prepared in the following proportion: one part of cement and one lime is taken for 10 parts of sawdust. The resulting dry mass should be poured with one and a half parts of water and a sufficiently thick and homogeneous solution should be obtained. The mixture is spread on the surface and distributed in a fairly even layer.

Important! It is advisable to use sawdust that has been dried for several months or better than a year.

Such material is very cheap and environmentally friendly, but it does not have such high thermal insulation as expanded clay or mineral wool. In addition, the process of its manufacture is laborious, and after laying it is required to repair the resulting cracks (and they are inevitable).

Materials for vapor and waterproofing

For a bath, vapor barrier of the ceiling is vital, otherwise rising moisture will not only worsen the thermal insulation properties of the insulation, but will also contribute to the development of fungi and mold on the ceiling itself and on the roof rafters. As a material for vapor barrier, specialized films and coatings are used. Particular attention should be paid to anti-condensation membranes. When buying vapor barrier films, it is advisable to choose those that have a foil layer.

Important! When working with such films, be careful not to allow any breaks in the vapor barrier material or foil layer, otherwise its protective properties will deteriorate significantly.

As for waterproofing, for it you can use both special films that can be found in any hardware store, as well as cheaper roofing material or dense polyethylene.

Common vapor barrier materials: 1. Geosynthetics. 2. PVC membrane. 3. Glassine. 4. Tol. 5. Aluminum foil. 6. Thermofol.

Floor ceiling insulation

There are three main types of ceilings in the bath:

- hemmed;

- panel;

- grazing.

Now we will consider the last type and find out how to insulate it and what nuances should be taken into account.

The floor ceiling is usually used for small-sized baths, which are heated quite rarely and seasonally. On the upper part of the wall, sheet piles or simple edged boards, adjusted to each other and fixed, without the use of support beams. The resulting design is very simple, but at the same time it is unable to withstand a large load, therefore it is impossible to use a thick layer of thermal insulation here.

Important! It is advisable to lay a flat ceiling slightly lower than the height of the walls in order to leave space for filling expanded clay or laying mineral wool. If this is not possible, then along the perimeter of the ceiling under the roof, the sides should be nailed.

Step-by-step insulation of the bath flooring ceiling is as follows.

- From the side of the attic, a vapor barrier film is laid on the flooring so that the foil layer is directed downwards. The material should be overlapped by 10-15 centimeters, the seams and joints are sealed with foil tape.

- Mineral wool is laid on top of the vapor barrier, expanded clay is poured or a mixture of cement and sawdust is laid, depending on your choice. Please note that it is undesirable to use too thick a layer of insulation, since the flooring is not suitable for high loads.

- The heat insulator layer is closed from above with roofing felt, polyethylene film or waterproofing coating, overlapping and with careful gluing of the joints.

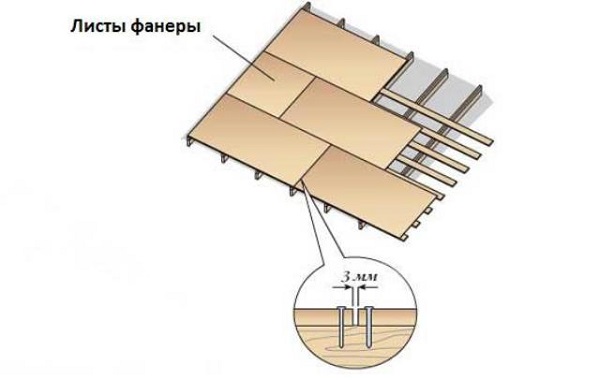

- The final step will be laying sheets of plywood or boards on top of the resulting “layer cake”.

It makes sense to use a flat ceiling in small baths and in the case when simplicity and speed of its installation and installation of insulation are important to you. If you are planning to make a large enough steam room or arrange an attic under the roof for storing bath accessories, then you should stop your choice on a false ceiling.

False ceiling insulation

Here, not the flooring itself is laid on the upper part of the wall, but the support beams made of wooden beam or boards glued together. And already from below and above, the ceiling and the floor of the attic are laid on the beams. At the same time, layers of steam, hydro and thermal insulation are laid in the space between them.

The process of insulating a ceiling with a similar design depends on what material you use. For mineral wool, this happens as follows.

Video - We insulate the ceiling in a bath with a cold roof using mineral wool

The process of warming the hemmed ceiling of a bath with a cold roof looks a little different in the case when expanded clay or a cement-sawdust mixture is used. Let's put it in the form of a step by step guide.

- From below, a rough flooring of boards is laid on the floor beams. The gaps between them must be treated with a sealant or smeared with a mixture of clay (or concrete) and sawdust.

- A vapor barrier film is laid on the flooring both from the side of the steam room and from the side of the roof, and not only the boardwalk, but also the beams themselves should be covered.

- Expanded clay is poured into the resulting boxes or ecowool is laid.

- A ruberoid or other overlap is laid over the insulation waterproofing material and attached to the beams with construction stapler.

- Boards or plywood are laid on the waterproofing to form the attic floor.

- A lining is laid on the draft boards from below.

If you use a mixture of clay and sawdust to insulate the ceiling, then it is advisable to put a layer of mineral wool or expanded clay on top of the frozen mixture - this will improve the performance of thermal insulation.

Important! Optimal Thickness a layer of a mixture of clay and sawdust for using a bath in the warm season is 50 mm. If you plan to bathe in it in winter, then you will need to make a layer of insulation of at least 150 mm.

Panel ceiling insulation

This ceiling design is the most difficult for self-manufacturing- first you need to make the panels themselves, and then lift them up and fix them either on the cross beams or directly on the top of the walls.

Each of the panels is made as follows.

- A layer of boards, carefully adjusted to each other, is laid perpendicular to the supporting bars. This layer will serve as the ceiling for the bath.

- Boards are attached to the inside of the resulting shield, which will serve as the sides of the panel.

- A vapor barrier material is laid on the boards and sides and fixed with a construction stapler.

- Mineral wool or ecowool is laid in the interior space of each panel. You can also use a cement-sawdust mixture or expanded clay, but in this case the panel will turn out to be especially heavy.

- On top of the heat-insulating material is laid polyethylene film or roofing felt, with overlapping joints of 5-10 cm.

- Fits upper layer boards that will serve as the floor for the attic.

The resulting panels should be lifted and mounted, while it will not be superfluous to lay solid boards on top and bottom of them, connecting all the panels to each other. The joints between them also need to be insulated with strips of mineral wool scraps. Alternatively, you can take the same mixture of cement and sawdust.

Advice! Assembly itself ceiling panels, their lifting and installation is very laborious. Therefore, it is desirable to use some lifting device and work not alone or in pairs, but as a whole team.

Choose the type of ceiling and used insulation material follows from the budget own experience construction work, the area of the bath and how often it will be used.

Video - Device ceiling in the bath

- aluminium foil;

- wax paper.

- Vapor barrier membrane.

Types of insulation materials

ceiling insulation technology

The insulated ceiling is ready.

The heated air tends to rise and, if there is no obstacle in its way, it goes into the atmosphere. This barrier is the ceiling. In case of insufficient insulation, about 2/3 of the thermal energy can go through it. Therefore, in order not to incur unnecessary expenses for heating the street, it is necessary to insulate the ceiling of the bath with your own hands. Everything should be organized in such a way that condensation does not form on the wood, and because of it, microorganisms that can destroy the building material do not appear.

Types of baths in accordance with the characteristics of the roof

Depending on the design features roofs log baths or baths from a bar are divided into buildings with and without an attic.

Baths with an attic have a significantly more powerful ceiling, which prevents warm air from escaping from the room. In this case, the thermal insulation of the bath ceiling

produced during the construction process. The air mass that fills the space under the roof also helps to reduce losses. The heat will be delayed a little more by the roof insulation.

In a building that does not have an attic, there are much fewer barriers to heat retention and they are too weak, so insulation is especially necessary here. But it is also necessary to do the insulation of the ceiling in a bathhouse with an attic or attic.

Features of the vapor barrier device

In any case, the vapor barrier material is laid first, and only then the heat-insulating material.

The following materials are used as a vapor barrier in baths without an attic:

- aluminium foil;

- thick cardboard, well impregnated with drying oil;

- wax paper.

For buildings with an attic, the same materials are used, but clay is most often used. It is applied to the ceiling boards from the side of the roof with a layer equal to 2 cm (read also: “How to insulate the roof of a bathhouse with your own hands - choose the material and method of insulation”).

Of the materials produced by the industry, the following are used:

- Polyethylene film (0.4 mm with variations). It creates a greenhouse effect and therefore is not popular. When using this material, leave a gap that is required to evaporate the resulting condensate.

- A special vapor barrier polyethylene film with villi that are able to retain condensate.

- Vapor barrier membrane.

The main task of vapor barrier is to retain steam and prevent it from entering the insulation. Due to the accumulated moisture, the service life of the heat-insulating material is reduced, the weight of the ceiling structure increases, and the quality of the insulation decreases.

Functions of bath ceiling insulation

With an increase in the required temperature in the room, the construction of a barrier to prevent heat loss becomes more complicated. Decide this problem allows the laying of heat-insulating material in a multi-layer ceiling structure.

Thermal insulation eliminates the following types of thermal leaks:

- heat loss through ceiling cracks;

- the gradual movement of heat from warm objects to cold ones;

- overcoming homogeneous barriers with warm air.

With the proper organization of insulation, all the functions assigned to it will be implemented. In the case of illiterate thermal insulation, problems such as the formation of condensate, long heating of the room and the waste of more fuel can occur.

Types of insulation materials

Before starting work on thermal insulation, it is necessary to choose how to insulate the attic of the bath.

Mineral wool is a randomly intertwined fibers, air voids are formed between them, which perform the function of retaining heat. This insulation on the ceiling in the bath is used most often. When wet, mineral wool loses its thermal insulation properties. If the roof has insufficient protection against rainwater leakage, then it is recommended to lay a waterproofing material on top of the insulation. There must be a thermal insulation gap between the layers of waterproofing and insulation.

Also, the ceiling in the bath can be insulated with foamed polypropylene. This material is very light and will not weigh down the ceiling structure. Especially for baths and saunas, a material foiled on one side was developed. In addition to the main function of insulation, it reflects the heat flow with the foil side. Acting on the principle of a mirror, this insulating material provides faster heating of the steam room.

Expanded clay can also be used as a heater for the ceiling in the bath. It is used in large baths. It is necessary to fill up expanded clay with a uniform layer equal to 30 cm. The material is relatively light, but, nevertheless, the weight of the ceiling structure will increase. This insulation material, like mineral wool, absorbs moisture well, so a waterproofing layer is also needed.

Another option than to insulate the ceiling in the bath with your own hands is the so-called "folk" heat insulator.

In this case, the insulation is carried out as follows:

- Soft clay is laid with a layer of 2 cm. It can be replaced with a mixture of black soil and peat, wood shavings, which is poured cement mortar, you can also mix clay with sawdust or sand.

- Sawdust or oak leaves fall asleep (you can replace any others).

- Dry earth is poured with a layer equal to 15 cm.

Also, growing aerated concrete is used to insulate the ceiling in the bath. To fill it, it is necessary to make a simple formwork.

The thickness of the insulation layer depends on the amount of heat loss and technical parameters baths. Also, when calculating, it is necessary to take into account climatic conditions, since the insulation of the ceiling in a bath with a cold roof not only prevents heat from leaving the room, but also protects against the penetration of cold air from the street. When the outside of the ceiling freezes, condensation will form on the ceiling. To eliminate this problem, it is necessary to increase the thermal insulation layer. See also: "Proper warming of the steam room from the inside - advice from the master."

Here are different kinds thermal insulation materials. Which one then better insulation for the ceiling in the bath, use is determined in each case.

ceiling insulation technology

Regardless of what material the bath is built from, there are almost no differences in the device of its upper floor. Beams act as a supporting base. They are laid on the upper crowns of logs or timber, and if the structure is brick or panel, then the Mauerlat serves as a support for the beams. See also: How to insulate brick bath right by hand."

Before installation, the timber used for the beam ceiling must be treated with an antiseptic. But if the wood has not been treated by special means in advance, then this must be done before starting work on laying the heat-insulating material. Particularly careful processing is required at the points of contact between wood and materials such as brick, foam concrete, and metal. See also: "How and how to make the insulation of the bath outside - options and examples."

Consider step by step how to properly insulate the ceiling in the bath:

- Boards are attached to the bottom of the beams.

- Roll-up shields are made, that is, low-quality boards are taken and two rows perpendicular to each other are knocked together. It should look like a box. Before knocking down the roll-over shields on the ceiling to the bath with your own hands, it is necessary to make calculations. Beams and shields should not be located close to each other, between them it is necessary to leave gaps equal to at least 5 cm. From the chimney to wooden shields there should be a distance of at least 25 cm. It is necessary to draw a diagram, and in accordance with it, calculate the dimensions and shape of each of the shields. To avoid confusion during installation, all shields must be numbered.

- Finished shields also need to be impregnated with antiseptic agents.

- Inside each shield there is a vapor barrier in the bath. It must be secured with staples.

- The shields go up. You need to start with those that will be installed last.

- Shields are placed in accordance with the numbering. Installation is carried out in such a way that the lower planes of the shield and the beam coincide.

- Then, heat-insulating material is placed in the "boxes". It is also necessary to insulate the joints between the shields and beams. The owners of the bath independently select the better to insulate the ceiling in the bath. The choice depends on a combination of various factors.

- Boards are laid on top. They must be placed across the beams. In this case, it is not necessary to take the board to its full length; short boards can also be used. Boards can be replaced with fiberboard or self-made slabs from a solution of cement mixed with sawdust.

- The finished ceiling should be treated with fire-fighting agents.

- All wooden elements located near the chimney must be covered with asbestos sheets.

The insulated ceiling is ready.

Thermal insulation of the ceiling in the steam room

The ceiling of the steam room should perform two functions: keep warm air and steam out and ensure the accumulation of steam in the room. The ceiling of the steam room should contain two layers of vapor barrier and additional layers of thermal insulation.

Consider several options for installing the ceiling in the steam room.

Design from Sosnin Yu.P. and Bukharkina E.N.

- Groove boards 25 mm thick are taken and attached to the beams. The boards must be covered with drying oil in two layers, which should give them moisture resistance.

- Boards of poor quality are fastened across the top of the beams. There should be a distance of 3 cm between them. In this way, a moisture gap is created.

- Further, a roofing material or plastic film spreads over the boards. Reinforced foil works best.

- Slag or sand falls asleep. The layer should be equal to 20 cm.

Other ways to insulate the ceiling in the steam room

The technology for performing thermal insulation using clay and mineral wool is as follows:

- For filing from below to the ceiling beams, an unedged board 5 cm thick is used.

- Outside, a narrow board is attached along the beams with the help of capercaillie. It is required to support the binder.

- Grooved aspen boards are screwed to a fixed thin board, a ventilation gap must be left between them.

- From the side of the attic, a vapor barrier material is spread.

- Then a layer of 3 cm is laid mixed with sawdust clay.

- Mineral wool is laid. You should take a heater with a density of 125 units and having a width of 15 cm.

- A polypropylene film is spread to protect against wind.

- At the end, the floor of the attic is made from the boards

If there is a log ceiling in the bath, then the crate is first made, and then the sheathing is attached to it. As a vapor barrier, glassine spreads on top. Then sand is poured with a layer equal to 20 cm. The rest of the actions depend on the desire of the owner of the bath.

For proper insulation of the bath, you need to know which insulation is best for the bath on the ceiling, in what order you need to arrange the layers, as well as the features of the ceiling insulation in the steam room. The options for arranging the ceiling described above can be changed depending on climatic conditions and personal preferences.

How to insulate the ceiling in the bath correctly - do-it-yourself insulation options

The heated air tends to rise and, if there is no obstacle in its way, it goes into the atmosphere. This barrier is the ceiling. In case of insufficient insulation, about 2/3 of the thermal energy can go through it. Therefore, in order not to incur unnecessary expenses for heating the street, it is necessary to insulate the ceiling of the bath with your own hands. Everything should be organized in such a way that condensation does not form on the wood, and because of it, microorganisms that can destroy the building material do not appear.

Types of baths in accordance with the characteristics of the roof

Depending on the structural features of the roof, log saunas or log saunas are divided into buildings with and without an attic.

Baths with an attic have a significantly more powerful ceiling, which prevents warm air from escaping from the room. In this case, the thermal insulation of the bath ceiling

produced during the construction process. The air mass that fills the space under the roof also helps to reduce losses. The heat will be delayed a little more by the roof insulation.

In a building that does not have an attic, there are much fewer barriers to heat retention and they are too weak, so insulation is especially necessary here. But it is also necessary to do the insulation of the ceiling in a bathhouse with an attic or attic.

Features of the vapor barrier device

In any case, the vapor barrier material is laid first, and only then the heat-insulating material.

The following materials are used as a vapor barrier in baths without an attic:

- aluminium foil;

- thick cardboard, well impregnated with drying oil;

- wax paper.

For buildings with an attic, the same materials are used, but clay is most often used. It is applied to the ceiling boards from the side of the roof with a layer equal to 2 cm (read also: “How to insulate the roof of a bathhouse with your own hands - choose the material and method of insulation”).

Of the materials produced by the industry, the following are used:

- Polyethylene film (0.4 mm with variations). It creates a greenhouse effect and therefore is not popular. When using this material, leave a gap that is required to evaporate the resulting condensate.

- A special vapor barrier polyethylene film with villi that are able to retain condensate.

- Vapor barrier membrane.

The main task of vapor barrier is to retain steam and prevent it from entering the insulation. Due to the accumulated moisture, the service life of the heat-insulating material is reduced, the weight of the ceiling structure increases, and the quality of the insulation decreases.

Functions of bath ceiling insulation

With an increase in the required temperature in the room, the construction of a barrier to prevent heat loss becomes more complicated. This problem can be solved by laying heat-insulating material in a multilayer ceiling structure.

Thermal insulation eliminates the following types of thermal leaks:

- heat loss through ceiling cracks;

- the gradual movement of heat from warm objects to cold ones;

- overcoming homogeneous barriers with warm air.

With the proper organization of insulation, all the functions assigned to it will be implemented. In the case of illiterate thermal insulation, problems such as the formation of condensate, long heating of the room and the waste of more fuel can occur.

Types of insulation materials

Before starting work on thermal insulation, it is necessary to choose how to insulate the attic of the bath.

Mineral wool is a randomly intertwined fibers, air voids are formed between them, which perform the function of retaining heat. This insulation on the ceiling in the bath is used most often. When wet, mineral wool loses its thermal insulation properties. If the roof has insufficient protection against rainwater leakage, then it is recommended to lay a waterproofing material on top of the insulation. There must be a thermal insulation gap between the layers of waterproofing and insulation.

Also, the ceiling in the bath can be insulated with foamed polypropylene. This material is very light and will not weigh down the ceiling structure. Especially for baths and saunas, a material foiled on one side was developed. In addition to the main function of insulation, it reflects the heat flow with the foil side. Acting on the principle of a mirror, this insulating material provides faster heating of the steam room.

Expanded clay can also be used as a heater for the ceiling in the bath. It is used in large baths. It is necessary to fill up expanded clay with a uniform layer equal to 30 cm. The material is relatively light, but, nevertheless, the weight of the ceiling structure will increase. This insulation material, like mineral wool, absorbs moisture well, so a waterproofing layer is also needed.

Another option than to insulate the ceiling in the bath with your own hands is the so-called "folk" heat insulator.

In this case, the insulation is carried out as follows:

- Soft clay is laid with a layer of 2 cm. It can be replaced with a mixture of black soil and peat, wood shavings, which is poured with cement mortar, and clay can also be mixed with sawdust or sand.

- Sawdust or oak leaves fall asleep (you can replace any others).

- Dry earth is poured with a layer equal to 15 cm.

Also, growing aerated concrete is used to insulate the ceiling in the bath. To fill it, it is necessary to make a simple formwork.

The thickness of the insulation layer depends on the amount of heat loss and the technical parameters of the bath. Also, when calculating, it is necessary to take into account climatic conditions, since the insulation of the ceiling in a bath with a cold roof not only prevents heat from leaving the room, but also protects against the penetration of cold air from the street. When the outside of the ceiling freezes, condensation will form on the ceiling. To eliminate this problem, it is necessary to increase the thermal insulation layer. See also: "Proper warming of the steam room from the inside - advice from the master."

Here are the different types of thermal insulation materials. And what is the best insulation for the ceiling in the bath to use is determined in each case.

ceiling insulation technology

Regardless of what material the bath is built from, there are almost no differences in the device of its upper floor. Beams act as a supporting base. They are laid on the upper crowns of logs or timber, and if the structure is brick or panel, then the Mauerlat serves as a support for the beams. See also: "How to insulate a brick bath with your own hands correctly."

Before installation, the timber used for the beam ceiling must be treated with an antiseptic. But if the wood has not been treated with special means in advance, then this must be done before starting work on laying the heat-insulating material. Particularly careful processing is required at the points of contact between wood and materials such as brick, foam concrete, and metal. See also: "How and how to make the insulation of the bath outside - options and examples."

Consider step by step how to properly insulate the ceiling in the bath:

- Boards are attached to the bottom of the beams.

- Roll-up shields are made, that is, low-quality boards are taken and two rows perpendicular to each other are knocked together. It should look like a box. Before knocking down the roll-over shields on the ceiling to the bath with your own hands, it is necessary to make calculations. Beams and shields should not be located close to each other, between them it is necessary to leave gaps equal to at least 5 cm. There must be a distance of at least 25 cm from the chimney to wooden shields. It is necessary to draw a diagram, and in accordance with it, calculate the dimensions and shape of each of the shields . To avoid confusion during installation, all shields must be numbered.

- Finished shields also need to be impregnated with antiseptic agents.

- Inside each shield there is a vapor barrier in the bath. It must be secured with staples.

- The shields go up. You need to start with those that will be installed last.

- Shields are placed in accordance with the numbering. Installation is carried out in such a way that the lower planes of the shield and the beam coincide.

- Then, heat-insulating material is placed in the "boxes". It is also necessary to insulate the joints between the shields and beams. The owners of the bath independently select the better to insulate the ceiling in the bath. The choice depends on a combination of various factors.

- Boards are laid on top. They must be placed across the beams. In this case, it is not necessary to take the board to its full length; short boards can also be used. Boards can be replaced with fiberboard or self-made slabs from a solution of cement mixed with sawdust.

- The finished ceiling should be treated with fire-fighting agents.

- All wooden elements located near the chimney must be covered with asbestos sheets.

The insulated ceiling is ready.

Thermal insulation of the ceiling in the steam room

The ceiling of the steam room should perform two functions: keep warm air and steam out and ensure the accumulation of steam in the room. The ceiling of the steam room should contain two layers of vapor barrier and additional layers of thermal insulation.

Consider several options for installing the ceiling in the steam room.

Design from Sosnin Yu.P. and Bukharkina E.N.

- Groove boards 25 mm thick are taken and attached to the beams. The boards must be covered with drying oil in two layers, which should give them moisture resistance.

- Boards of poor quality are fastened across the top of the beams. There should be a distance of 3 cm between them. In this way, a moisture gap is created.

- Further, a roofing material or plastic film spreads over the boards. Reinforced foil works best.

- Slag or sand falls asleep. The layer should be equal to 20 cm.

Other ways to insulate the ceiling in the steam room

The technology for performing thermal insulation using clay and mineral wool is as follows:

- For filing from below to the ceiling beams, an unedged board 5 cm thick is used.

- Outside, a narrow board is attached along the beams with the help of capercaillie. It is required to support the binder.

- Grooved aspen boards are screwed to a fixed thin board, a ventilation gap must be left between them.

- From the side of the attic, a vapor barrier material is spread.

- Then a layer of 3 cm is laid mixed with sawdust clay.

- Mineral wool is laid. You should take a heater with a density of 125 units and having a width of 15 cm.

- A polypropylene film is spread to protect against wind.

- At the end, the floor of the attic is made from the boards

If there is a log ceiling in the bath, then the crate is first made, and then the sheathing is attached to it. As a vapor barrier, glassine spreads on top. Then sand is poured with a layer equal to 20 cm. The rest of the actions depend on the desire of the owner of the bath.

For proper insulation of the bath, you need to know which insulation is best for the bath on the ceiling, in what order you need to arrange the layers, as well as the features of the ceiling insulation in the steam room. The options for arranging the ceiling described above can be changed depending on climatic conditions and personal preferences.

How to properly insulate the ceiling under a cold roof?

Currently, almost all residential buildings are heated using gas or electric heat generating equipment. Even summer cottages and garden houses which are used only in summer. Most buildings that are not used year-round are equipped with inexpensive cold-type roofs, through which the main heat loss occurs while maintaining a comfortable temperature regime. In this article, we will tell you how to properly insulate the ceiling under a cold roof so that the house is always warm.

Features of the device of cold roofs

The design of the roof depends on the nature of the use of the house and the under-roof space. It is these factors that determine the choice of form, roofing material, scheme roof frame and the presence or absence of a thermal insulation layer . In private housing construction, 2 types of roofs are used:

- Warm roof. This type of roofing construction provides for complete insulation of slopes. A warm roof is installed if the room located under the slopes is used as a residential one. She is considered great option for residential attic equipment. It makes sense to build roofs of this type for houses used and heated all year round, since they exclude heat loss through the slopes. The cost of materials and installation work for the construction of a warm roof is much higher than the cost of building a cold one.

Important! If the attic space is not heated, then the air in it serves as a kind of buffer zone, which acts as thermal insulation and reduces heat loss. The air rising from the heated rooms on the first floor, according to the law of convection, gradually cools and does not heat the surface of the slopes from the inside, so that frost does not form on them.

To keep warm as well as reduce fuel consumption to maintain optimal temperature, with the help of bulk or fibrous thermal insulation materials insulate the ceiling, located under a cold roof. Since heated air always rises, this operation is an effective measure to reduce heat loss.

Thermal insulation methods

High-quality thermal insulation reduces heat losses and the cost of heating a house by 30%, which is a good savings on a family budget. Use of suitable insulation and right choice installation methods form a comfortable microclimate in the room.

The issue of thermal insulation of the ceiling under a cold roof is best addressed at the stage of building a house, then you can choose the most effective and convenient option. Most often, the insulation is mounted in 2 ways:

- Insulation from the attic. The most effective and correct builders consider the insulation of the ceiling, located under the cold roof from the side of the attic. The fact is that the ceiling is most often built of wood, which in itself is a good peat insulating material. In this case, the insulation is laid on the attic floor and covered with a subfloor. If the insulation is carried out from the side of the attic, then materials in the form of slabs or backfill can be used.

Insulation from the first floor. In cases where there is no access to the attic, when old houses are being reconstructed with a finished attic floor, thermal insulation is performed from the side of the first floor. To do this, a metal profile frame is mounted on the ceiling or wooden slats, lay insulation plates there, and then sheathe them with drywall. The disadvantage of this method is that it reduces the height of the ceiling. In addition, installation at the top is always much more difficult and longer. The effectiveness of this method of insulation is less, so it is used when there is no other way to reduce heat loss without dismantling the ceilings.

Note! Any thermal insulation works in a complex way. Therefore, if you want to solve problems with heat loss in a house with a cold roof, do not forget about the thermal insulation of the floor, door and window openings. A clear way to analyze where the heat goes is to look at the house in the thermal imager in winter. To increase the energy efficiency of your home, you need to pay attention to the areas colored in red and yellow, it is through them that heat escapes.

materials

The modern building market offers an impressive range of thermal insulation materials, but not all of them are suitable for cold roof ceiling insulation. In order for the costs to recover, it is necessary that the thermal insulation layer is resistant to moisture, has low thermal conductivity and meets safety standards for human health.

The following materials are used for insulation:

- Expanded clay. Expanded clay is called a bulk-type insulation, which is obtained by firing shale. It has a light weight, porous structure and high thermal insulation properties, but is not afraid of moisture. To insulate the ceiling with this material, a vapor barrier film is laid on the attic floor, fixed with a construction stapler, and then expanded clay is covered with a layer of 15-30 cm.

Experienced craftsmen remind that important role in the insulation of the floor located under the cold roof, vapor barrier and waterproofing layers play. To protect the insulation from getting wet as a result of interaction with heated air saturated with water vapor, a vapor barrier membrane is first laid. And from the side of the roof, it is protected from leaks with a waterproofing film.

Video instruction

How to insulate the ceiling in a bath with a cold roof?

If the ceiling is not insulated in a bath with a cold roof, condensate will accumulate on its surface. Chilled drops of water dripping from above on people in the bath will clearly deprive them of the expected pleasure. Droplets of water falling further upwards with warm air currents will contribute to rotting and complete destruction of the ceilings, and in general - the roof truss structure. The only way to prevent the occurrence of such troubles will be the arrangement of ceiling insulation in a bath with a cold roof.

Planning work on the thermal insulation of the roof of the bath

Before purchasing the building materials necessary for work and preparing the right tools, you need to draw up a detailed plan for the insulation work performed. Drawing up a plan will avoid mistakes and alterations of the roof structure.

The process of thermal insulation of the ceiling and roof of the bath is not a very laborious work, therefore it is easy to do it yourself, even in the absence of sufficient experience in repair and construction work. The main thing is that it is necessary to strictly adhere to the sequence (technology) of performing installation operations. Another argument for self-insulating the ceiling is the availability of the necessary heat-insulating materials - they are available in almost all hardware stores.

Insulation of the ceiling in a bath with a cold roof includes 3 stages:

- Thermal insulation.

- Laying a layer of vapor barrier.

- Waterproofing.

At the end of the work, a structure is obtained that looks like a layer cake, in which the lowest layer is the ceiling ceiling, and layers are successively located above it: steam, heat and waterproofing. Then you can start choosing the necessary building materials.

The choice of heat insulator for the roof and ceiling of the bath

In a well-heated bath, it is necessary to maintain sufficiently high values \u200b\u200bof humidity and temperature. The heat-insulating building material must be fully suitable for such requirements and, most importantly, it must not emit substances hazardous to people and the environment during heating. And besides this, a good heat insulator for a bathhouse should not support combustion, be excessively heavy and inconvenient for moving and laying.

mineral wool

One of the most common options for fibrous heat insulators for ceiling insulation in a bath with a cold roof and individual housing construction, produced in 3 types:

- glass wool;

- slag wool, produced from blast furnace waste (slag);

- stone wool is made from melts of basalt and other minerals.

The main advantage of mineral wool, in addition to very low indicators of heat conductivity: mold and fungus spores do not develop on it, and insects and rodents bypass it. For hosted on land plot bath rooms, this advantage of mineral wool is very important. It should also be noted that this building material does not change its volume and shape when the ambient temperature changes, it does not support combustion, it is very convenient for installation, due to its low weight. Mineral wool is produced in rolls or in the form of rectangular sheets/panels.

There are two disadvantages of mineral wool - this is the high ability of mineral wool to absorb any moisture (especially slag wool) and the phenolic compounds contained in it. These 2 shortcomings are easily eliminated: with the help of good hydro and vapor barriers and preventing contact between air flows and mineral wool, especially in the inside of the bathhouse.

Important: when performing any work with mineral wool, you must be in a tight outerwear, and use protective devices(goggles and respirator) to protect the eyes and respiratory organs, as its small elements affect the skin, eyes and lungs of a person.

Expanded clay

This building material is a small porous clay pebbles. For all its properties, expanded clay is considered the most suitable heat insulator to insulate the ceiling in a bath with a cold roof.

Warming the roof of the bath with expanded clay

Warming the roof of the bath with expanded clay

This material is safe - it does not support combustion, does not harm people and environment, does not emit polluting and harmful substances to humans. Expanded clay - durable, does not collapse under the influence of the sun's rays. In this building material, spores of fungi and bacteria do not develop, it is inexpensive and its installation is simple.

Expanded clay also absorbs much less water than mineral wool, however, it is also necessary to use hydro- and vapor barriers for its laying.

Styrofoam

More recently, this heat insulator was one of the most popular among all heat-insulating building materials. But, despite its excellent heat-insulating properties, foam plastic cannot be used to insulate the roof or ceiling of the bath - this building material is combustible, and when burned, it emits toxic substances that are dangerous to human life. It can also decompose and lose shape when exposed to high temperatures in the bath.

Ecowool

This is a fibrous natural heat insulator made from cellulose fibers with various additives that give additional properties - resistance to burning and protecting against the appearance of rodents, microorganisms and insects. Ecowool has a small specific gravity and can fill absolutely all gaps and crevices.

Like expanded clay, ecowool is an environmentally friendly heat insulator that does not emit hazardous substances into the air.

Roof insulation with ecowool

Roof insulation with ecowool

However, this heat insulator has a significant drawback - it absorbs a lot of liquid, which leads to a deterioration in heat-insulating properties. Therefore, when using ecowool, excellent ventilation of the under-roof space and a high-quality waterproofing layer are necessary. Another disadvantage of its use is the complexity of laying; with a “wet” installation method, special equipment is required.

A mixture of cement and sawdust

This is a "classic" building material-insulation, which was used before the advent of polystyrene foam and mineral wool. Sometimes clay is used instead of Portland cement, and sawdust is replaced with straw.

Important: the sawdust used in this mixture must be dried for several months, and even better - for a year.

This is a very cheap and environmentally friendly heat insulator, but with low heat-insulating characteristics. In addition, the preparation of the mixture is very laborious.

Materials for hydro and vapor barrier

The vapor barrier of the ceiling in the bath is very important, otherwise the moisture circulating in the room will worsen the properties of the heat insulator and lead to the development of mold and fungi both on the ceiling itself and on the details of the truss structure. For vapor barrier, special films and coatings are most often used - in particular, with anti-condensation membranes (preferably with a layer of foil). Leading places on this moment, the market is occupied by TechnoNIKOL vapor barriers.

As a waterproofing agent, you can also use both special films and cheaper building materials - roofing material or thick polyethylene.

Insulation of the ceiling in the baths

There are 3 main types of ceilings in baths:

The floor-type ceiling is common in small baths, which are used seasonally and quite rarely. On the upper parts of the walls are placed boards adjusted to each other, fixed without support beams. The resulting design is very simple, but it cannot withstand a lot of weight, so the heat insulator layer must be thin and light.

Important: a floor-type ceiling must be erected just below the upper boundary of the walls in order to get space for filling expanded clay or placing mineral wool.

From the side of the attic space, a film vapor barrier is placed on the flooring so that the foil on it is directed downwards. The vapor barrier itself is laid with an overlap of 10-15 cm, and the joints and seams are sealed with special adhesive tape for vapor barrier with a layer of foil.

Mineral wool is laid on top of the vapor barrier, expanded clay or a cement-sawdust mixture is placed. The layer of insulation should not be thick.

Then the heat-insulating layer is closed from above with a waterproofing agent (film or roofing material), on top of which boards or plywood sheets.

Hemming type ceiling insulation

For a ceiling of this type, not flooring is placed on the upper parts of the walls, but supporting wooden beams made from beams or finger-jointed boards. Then, the floor of the attic and the ceiling are placed on these support beams from below and above. And in the space between the attic floor and the ceiling, layers of heat, steam and waterproofing are mounted.

Stages of the installation of a false ceiling in the bath

Stages of the installation of a false ceiling in the bath

The process of placing a heat insulator is performed as follows. From the side of the roof on the beams, a film waterproofing agent is placed and attached with a stapler. Next, boards or plywood sheets are laid on top of it. The hemmed-type ceiling is durable, so the resulting under-roof space can even be used as an attic.

Mineral wool is placed between the beams. The thickness of the heat insulator depends on the location of the bath structure: for mid-latitudes 15.0-18.0 cm, in areas with severe winter frosts - 20.0-25.0 cm. Layers of heat-insulating building material are laid so that the joints of the previous layer overlap with the next layer .

A vapor barrier film is attached to the floor beams from below. On top of the vapor barrier, the slats are fixed perpendicular to the beams.

After that, the lining is laid, which is nailed or fixed with screws directly to the rails.

Insulation of a panel-type ceiling is the most difficult and is practically not used for self-production. First, the panels are made directly, and then they are lifted up and fixed - either on the cross-beams or on the upper parts of the walls.

Important: the choice of the type of ceiling and heat-insulating building material must be carried out based on the planned budget, building experience, the area of \u200b\u200bthe bathhouse and the frequency of its use.

Greetings, dear readers, the topic of today's article is how to insulate the ceiling of the bath and how it is better to do it. In the last article, we chose optimal height ceiling, now let's go directly to the device and the insulation of the ceiling of the bath.

A bit of theory. We all know that warm air is lighter than cold air and rises to the ceiling. And imagine the situation - hot steam has risen up, and the ceiling is cold. What will happen? That's right, condensation will fall. You soar with brooms in the bath, and the rain drips on you :). Let's see how improper insulation of the ceiling and the lack of vapor barrier can harm:

- Constant wetting of ceilings and, as a result, their premature destruction.

- Very fast cooling of the bath, it is possible that in the cold season the steam room will not be able to warm up properly.

- Excessive consumption of firewood or electricity.

- The real danger of destruction of ceilings.

Proper ceiling insulation

In this we will tell you how to avoid all these problems and properly insulate the ceiling. The whole process can be divided into three key stages:

- Steam room ceiling insulation.

- Attic waterproofing.

- Vapor barrier.

We, as builders, at this time have a serious advantage over our ancestors - the modern construction market offers the widest range of various thermal insulation materials for every taste and budget. Let's look at the most popular thermal insulation materials.

How to insulate the ceiling in the bath - popular materials.

Mineral wool- the most common insulation material among our compatriots. It is highly valued for its good insulating qualities, ease of installation and, most importantly, cost. Mineral wool consists of many basalt threads intertwined in a chaotic manner, among which there are billions of tiny voids filled with air. Such a mixture of air and basalt keeps heat well and is great for warming the bath ceiling. But min. cotton wool has one big minus - it is afraid of moisture. When wet, mineral wool becomes very caked and loses its properties many times over. thermal insulation characteristics. Inexpensive and practical.

Expanded clay - given material often used in ceiling insulation. Expanded clay is a set of small granules, each of which weighs less than a gram. The required layer of expanded clay laying is 20-30 centimeters. Although one granule weighs practically nothing, such a mass of expanded clay in a small area of \u200b\u200bthe ceiling will exert a noticeable load on the ceiling, which must also be taken into account when designing.

The main materials of thermal insulation

Folk insulation- a mixture of clay, earth, sawdust or straw. Most a budget option but unfortunately not the best. A layer of earth (2-3 centimeters) is laid on the ceilings, a layer of sawdust or straw is laid on top of the earth.

Polypropylene- modern thermal insulation material, in Lately replaces mineral wool. It is very light and comfortable material foam structure, which is designed specifically for the insulation of saunas and baths. The material itself holds heat very well, and the foil side of the polypropylene reflects heat radiation in the manner of a mirror. The use of penotherm allows you to reduce the heating of saunas and baths by 2 or even 3 times.

How to insulate the ceiling in the bath

Let's proceed directly to the laying of thermal insulation. The ceiling device is made after roofing cake laid and the walls erected. The roof is especially important, otherwise your thermal insulation may suffer in the open air.

Consider the main methods of ceiling insulation in the bath:

- Flooring (for small baths).

- Hemming (for large baths).

- Panel (an alternative to the first two).

It also makes sense to consider two types of bath construction - with and without an attic. It is best to make a bath with an attic. Firstly, you will have a place to dry brooms :). Secondly, a large air gap between the ceiling and the roof will significantly reduce the heat loss of the ceiling and save on insulation. Of course, subject to competent roof insulation.

The most popular method of warming the bath

This method is suitable for baths with or without an attic. The main condition for insulation is mounted ceilings. Before starting the installation of thermal insulation, you need to treat the wooden beams with an antiseptic. We present to your attention, in my opinion, the most correct scheme heater installations:

- Stage 1. From the inside of the bath, we attach a layer of vapor barrier to the ceiling. We talked in detail about the vapor barrier of the ceilings in the bath in this article. In short, a vapor barrier that includes a layer of aluminum is best suited for a bath. Aluminum well protects the vapor barrier and thermal insulation from moisture, and also reflects heat radiation back into the room, which reduces the warm-up time by 2! times. The vapor barrier is attached to the beams using a construction stapler, the attachment points are best treated with a special heat-resistant sealant. The seams of the vapor barrier are glued with adhesive tape, the vapor barrier sheets are overlapped with a 4-5 centimeter approach.

Laying vapor barrier - sectional diagram

From another angle, white material - vapor barrier

Dense laying of thermal insulation

As you can see, even a novice in the construction business can do the insulation of the bath ceiling. In the attic, we also recommend that you lay special guides and lay floorboard. And the waterproofing is intact, and there is free access to the attic. You can start preparing brooms.

Folk method of warming

Watch a video on how to insulate the ceiling with clay, sawdust and straw.

Voting - your choice of insulation

Dear attendants, we are always happy feedback from our readers. Please leave your opinions about the warming of the bath, your advice and suggestions, we will be happy to add useful things to the article. And now I ask you to participate in the vote:

Ceiling insulation in a bath with a cold roof: 4 best ways

A cold roof is not designed to retain heat, so bathing in a bath with such a roof will be very uncomfortable. How to insulate the ceiling in the bath to avoid such a problem? We'll figure out.

Why insulate the ceiling in the bath

If the roof of a building is cold, it means that it is not insulated. The under-roof space is separated from the street only by a layer of waterproofing and roofing elements. This gives certain advantages:

- low weight of the structure;