Internal insulation of a bathhouse is one of the most important stages in the arrangement of this building. Without high-quality thermal insulation, the owner will have to spend much more resources on heating the steam room, and the atmosphere in the bathhouse itself without properly installed protection will leave much to be desired.

Since ancient times in Rus', moss, felt and even flax have been used to insulate baths, mainly due to the lack of other insulation materials - plant fiber either rots or dries, so today it is not used for basic thermal insulation.

Red moss - insulation

The main difference between insulating a bathhouse and a similar event in an ordinary home is simple: in the steam room you need to maintain the heat for as long as possible, i.e. heat should remain indoors for as long as possible.

Thermal insulation work in a bathhouse can be carried out using a wide variety of materials. Eg, ideal solution is a modern insulation based on stone wool with an applied foil coating - it does not burn, can withstand temperatures up to 750 degrees, effectively retains heat, does not rot, and is not of interest to rodents.

After reading the information below, you will get a complete theoretical understanding of the execution process internal insulation steam room, and also study the step-by-step instructions for self-installation thermal insulation materials.

Any construction, repair and finishing activities begin with the preparation of materials, without which the implementation of the planned work will simply be impossible. Pay due attention to studying the list below: it is better to spend a little time reading and immediately buy everything you need, than to later return to the store and buy more of what you forgot.

Insulation

The main component of the list under consideration. The modern market offers a wide range of thermal insulation materials, but not all of them are suitable for use in a steam room - humidity and temperature may be too much for you. To insulate a bathhouse, the following are most often used: expanded clay (floor insulation), materials based on stone wool, and expanded polystyrene.

Important! It is strongly not recommended to use polystyrene foam to insulate the steam room itself - at high temperatures, material of dubious quality can most likely emit substances harmful to human health.

Comparative characteristics of the mentioned materials are given in the following table.

Table. Comparison of popular bath insulation

| Evaluation criterion | |||

|---|---|---|---|

| Structure | Bulk material of natural origin. Presented in the form of granules with a cellular structure. | Fibrous structure. The arrangement of fibers is both vertical and horizontal, disordered. | Open cellular structure. |

| Moisture permeability | The material does not allow water to pass through. | Mineral wool insulation has virtually no tendency to absorb moisture. | Moisture permeability is extremely low. |

| Weight | Easy | Medium-light | Easy |

| Strength | High | Average | Average |

| Compression resistance | High | From low to medium, depending on the specific type of material and manufacturer technology. | Average |

| Toxicity | The material is safe | No toxic properties | Over time, it begins to release harmful substances |

| Possibility of use under high load conditions | Suitable | Depending on the brand of material | Not suitable |

| Tendency to decay | The material retains its original integrity for a long time | Durable insulation | Has a tendency to decay |

| UV resistance | Does not react in any way to exposure to sunlight | Characterized by high resistance to ultraviolet radiation | Long-term direct contacts with sunlight extremely negatively affect the performance characteristics of the material |

As noted, expanded clay is suitable for insulating bath floors. Bulk material allows you to provide the required thermal insulation of both wooden and concrete structures. Mineral wool insulation is optimal for insulating both walls and ceilings. The best option, as noted, is a thermal insulation material based on stone wool, equipped with an additional foil coating - key characteristics such insulation at a higher level.

Prices for mineral wool

mineral wool

In accordance with the current provisions of the technology for carrying out the work in question, the joints of the insulation boards must be glued with foil tape. This will create a sealed surface with the highest possible thermal insulation properties.

Prices for foil tape

foil tape

Elements thermal insulation coating are placed in the cells of a pre-assembled sheathing, for the assembly of which wooden blocks are used. Select the section of the beams in accordance with the thickness of the thermal insulation. For example, if you are installing a 10-centimeter thermal insulation layer, use bars with a similar thickness or width to assemble the frame.

Choose the distance between the bars 1-2 cm less than the width of the slabs or roll of insulation. For bulk materials, the optimal distance between the bars is 45-60 cm.

The sheathing elements (bars) are fixed using dowels/screws (if the surface is wooden) or anchors (if the base is stone). The length of the fasteners is also selected in accordance with the base material: for wood - 2-2.5 cm, for permanent structures - from 4 cm.

The specific length of fasteners is determined in accordance with the characteristics of their use. For example, during the installation of sheathing, the fasteners must be of such length that they ensure high-quality fixation of the beam/profile of the selected section. The cross-section of the beam itself, as well as the profile parameters, are determined in accordance with the thickness of the thermal insulation layer being installed.

Additional materials

In the case of insulating a bath using a material other than foil mineral wool, you will additionally have to purchase a water vapor barrier film.

If filling is planned concrete screed, the job set will increase to include the following positions:

- reinforcing mesh;

- mixture for pouring the screed or materials for preparing it yourself (cement, sand, water);

- lighthouses;

- damper tape;

- polyethylene.

Prices for water vapor barrier film

water vapor barrier film

The floors in the bathhouse can be wooden or concrete. The technology for arranging the direct thermal insulation layer does not have any special differences depending on the flooring material, except that in the case of a concrete structure it will be necessary to pour more expanded clay.

The thickness of the backfill is usually determined in accordance with the thickness of the walls. On average, a layer of expanded clay is poured at least 2 times thicker than the walls. If the height of the room allows, the thickness of the backfill can be further increased - this will help improve the efficiency of insulation.

First, for greater convenience of work and subsequently more accurate control of the evenness of the backfill, mark the base. To do this, it is enough to divide it with parallel lines into sections up to 1 m wide or along the length of the rule you use.

Important! If you are insulating a floor on the ground, at the very beginning, even before marking, you need to do the following:

- thoroughly compact the soil inside the base (if the foundation design assumes the presence of “free” soil, for example, in the case of strip supports);

- cover the walls with impregnation for waterproofing;

- cover the soil with a 10-centimeter layer of sand, spill it with water and compact it thoroughly;

- cover the sand with roofing felt with a 15-centimeter overlap on the walls. Also lay individual sheets of roofing felt with a 15-centimeter overlap. For fastening, use waterproof construction tape.

The exact procedure for insulating the floor with expanded clay, with illustrations and necessary explanations, is given in the following table.

Table. Insulation of a bath floor with expanded clay

| Stage | Illustration | Necessary clarifications |

|---|---|---|

| The film must be stretched so that its edges along the wall are higher than the floor level. If the base is already covered with roofing felt, there is no need to lay the film. |

|

| For example, a profile for drywall is suitable. The guides are set in accordance with the previously applied markings and secured in a suitable way, for example, screws or nails. | |

| Align the beacons by level. In the future, these auxiliary devices will help you fill the most even layer of expanded clay, which will ensure best quality carrying out further planned work. Determine the installation height of the guides in accordance with required thickness thermal insulation layer. Many developers do without guides, but this is a less convenient and accurate option. |

|

| Pour expanded clay |

| The previously installed guides will help you do this as efficiently as possible. |

| For leveling, we use a rule or an ordinary strip of suitable length. | |

| To make leveling the insulation more convenient, we can use various auxiliary devices. For example, a rake will come in handy in large areas. |

The floor is insulated and ready for further arrangement in accordance with the developer's plans. At the discretion of the owner, additional thermal insulation material, for example, mineral wool or expanded polystyrene, can be laid on top of the expanded clay.

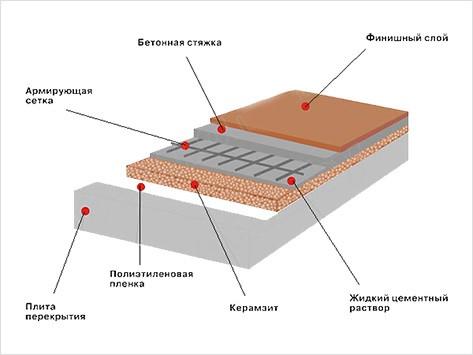

As an example, a diagram of a concrete floor equipped with expanded clay for thermal insulation is given.

Video - Floor insulation with expanded clay

Insulation of bath walls and ceilings

Wall insulation schemes will vary slightly depending on the material of manufacture. Information on this matter is presented in the following table.

Table. Wall insulation schemes

| Material of manufacture | Scheme |

|---|---|

|

|

1 – wall, 2 – thermal insulation, 3 – sheathing, 4 – cladding, 5 – ventilation gap. |

|

|

The sequence of thermal insulation work remains similar for walls made of any materials: if necessary, a water vapor barrier film is attached, sheathing bars are mounted, insulation is placed in the resulting cells, another layer of water vapor barrier is fixed on top (if necessary), sheathing slats are nailed for finishing cladding (at the same time they will provide the required ventilation gap), the selected finishing material (usually lining) is installed.

The ceiling is insulated in a similar sequence. An example of a ceiling insulation scheme is shown in the following image.

Information regarding step-by-step insulation walls and ceiling of the bathhouse is given in the following table.

Important! Insulation will be carried out with mineral wool material with a foil layer, which eliminates the need for preliminary fastening of a water vapor barrier material to the surface. The operating procedure is considered using the example of wooden surfaces. In a relationship concrete walls and floors, the recommendations are the same, the only thing is that you need to use other fasteners and for greater convenience, the wooden guides can be replaced with a metal profile.

Table. The procedure for insulating walls and ceilings in a bathhouse from the inside

| Work stage | Illustration | Necessary clarifications |

|---|---|---|

| Information regarding the elements used to construct the frame, as well as fasteners for fixing the guides in different cases was given earlier. The mounting step of the guides is selected in accordance with the width of the insulation. Typically this is about 60 cm, but can be reduced to 59-59.5 cm so that the thermal insulation elements fit as tightly as possible. |

|

| Rules for laying slabs |

| Be sure to put on gloves first - contact of “bare” skin with mineral wool does not give the most pleasant sensation. We place the foil material inside the room with foil - thanks to this, the heat will not only be retained, but will also be additionally reflected into the steam room. |

| The slabs are installed vertically into the frame and do not require additional mechanical fastening. | |

| Installation of slabs on the wall |

Installation of slabs on the wall | The sequence and recommendations for insulating walls and ceilings are similar. To insulate the partition separating the steam room from the adjacent room, a layer 50 mm thick is usually sufficient. |

| Thermal insulation external wall requires a thicker layer - 100-150 mm (in regions with a particularly cold climate - up to 200 mm). | |

| To save money, the insulation can be made in two layers, with one layer made of ordinary mineral wool, and the second, which will “look” into the room, made of foil-coated material. | |

| The use of such insulation, as noted, eliminates the need to use additional water vapor barrier materials. |

|

| Having filled the frame with heat-insulating boards, we glue the seams and joints with foil tape. | |

| A 1-2 cm gap is enough. The exterior trim will be attached to the same sheathing in the future. Important! The order of further installation of the lining depends on the location of the slats: if the slats are fixed vertically, the lining must be fixed horizontally, and vice versa. |

|

| The best material for internal lining The baths are clapboard. The choice of cladding material is at the discretion of the owner. Fixing the sheathing elements is traditionally done using screws/self-tapping screws. |

Video - Insulation of walls and ceilings from the inside

Now you know everything about how to properly insulate a bathhouse with your own hands using the most optimal thermal insulation materials. The information obtained will help you cope with the planned events yourself, eliminating the need to contact third-party specialists and saving significant money.

Good luck!

Video - Insulation of a bathhouse from the inside, diagram

The walls of a bathhouse built of brick or concrete definitely need insulation. After all, these materials do not tolerate high humidity and too sudden temperature changes very well. Cobblestone and log walls are subject to insulation if their thickness is less than 15 - 20 cm. Further in the article we will try to figure out how to insulate a bathhouse from the inside, quickly and without straining too much.

Necessary materials

To insulate the bath, we need the following material:

We will prepare the following tools: a hammer, a drill, a hacksaw and a hammer.

Advice: For cladding, you should take a board made of alder or linden. The wood of this species is resistant to moisture and does not heat up even at very high temperatures.

Expanded polystyrene cannot be used to insulate a bathhouse from the inside. When heated strongly, these plates begin to release toxic substances that are harmful to the body.

It is better to use basalt wool, and Penotherm NPP is most suitable as a vapor barrier. Its working and operating temperature reaches +150 degrees. The air in the steam room can only warm up to +100 - 120 degrees. Among other things, Penotherm is coated on the outside with foil. This will additionally ensure the preservation of heat in the steam room and washing room.

We insulate the walls

In order to properly insulate the walls, it is imperative to “stuff” the sheathing. There are two ways to install the sheathing - using wooden slats or installing aluminum construction. It is attached to wooden walls with nails, and to concrete walls with self-tapping screws. An aluminum frame will cost more and is more difficult to assemble, but it will also last in conditions high humidity longer.

Important: The spacing of the sheathing is maintained so that the wool can be placed apart, that is, a couple of centimeters closer to each other than the width of the slabs.

Paste a VALID AdSense code in Ads Elite Plugin options before activating it.

Mount the frame under the insulation vertically. This provides effective ventilation“pie” of walls. The lower cladding elements - which most often become unusable - are easier to replace with this method, since they will be located horizontally.

The technology for insulating a bathhouse from the inside is as follows:

- Basalt wool slabs are inserted into the sheathing.

- The vapor barrier is filling up. It is secured with slats about 3mm thick to ensure ventilation. Stretch Penotherm with foil towards the room.

- The sheathing is being installed. The lining is secured with clips or clamps. The boards are nailed (we must choose galvanized nails), pushing the latter into the wood with a hammer. You cannot leave the caps unclogged. Under the influence of hot steam, the metal heats up and you can get burned on the nails on the walls.

Working on the ceiling

The ceiling of the bathhouse should also be insulated. This procedure is usually performed externally. However, if erected pitched roof, this may prove difficult to achieve. In this situation, thermal insulation is done from the inside. Sheathing is done in the same manner as wall insulation. The only thing is that the slabs on the floor will have to be additionally secured with “fungi”. The thickness of the insulation should be at least 20 cm, since much more heat escapes through the ceiling in the steam room than through the walls. The overlap of the vapor barrier at the junction of the walls and ceiling is about 20 cm.

Insulation of floors, windows and doors

It will be possible to perfectly insulate a bathhouse from the inside only if close attention is paid to the floor. Mineral wool and expanded clay are used to insulate it. The floor itself is made slightly inclined and waterproofed. Water is drained by draining through a pipe into a receiving well. Cotton wool is also used to insulate windows. The door is lined with felt around the perimeter. It’s a good idea to additionally cover the fabric with cotton wool. Of course, there should be no gaps between the boards in the door leaf.

To make the bathhouse truly warm and cozy, the heater is installed in its center, usually near the wall separating the steam room and the dressing room.

In fact, the work of insulating a bathhouse from the inside is not particularly difficult. The main thing is to choose suitable materials and strictly follow the order of their installation.

Video on insulating a bathhouse from the inside:

Source: postroju-dom.ru

Insulating a bathhouse from the inside: cheap and safe

Step-by-step instructions for different bath wall materials

Insulation from the inside is an inevitable event for most types of baths. It allows you to spend less fuel, warm up the steam room faster and better. Properly done insulation protects the walls of the bathhouse from fungus and rotting, and extends its service life. In this article we will select inexpensive and safe types of thermal insulation depending on the material of the bathhouse walls, and consider how to install them correctly.

- Insulation of bathhouse walls from the inside: selecting insulation;

- Insulating a bathhouse from the inside with your own hands: from the ceiling to the floor;

- Insulation brick bath from the inside with your own hands;

- Insulation of a bathhouse made of blocks from the inside

- Insulation wooden bath from the inside

Insulation of a bathhouse from the inside: materials

Bathhouses are required for different rooms different requirements, we will focus on the steam room and washing room, the features of which are high temperature and high humidity. Also, the insulation is selected depending on the material of the bath walls.

But, regardless of the material of the walls and the purpose of the room, the insulation must be:

- Non-toxic so as not to cause poisoning when exposed to high temperature;

- Not hygroscopic, so as not to absorb moisture;

- Resistant to high temperatures and steam;

- Non-flammable;

- Maintaining its shape even after several years of extreme use;

- Resistant to fungi and mold;

- Sold at a reasonable price.

Bath insulation

| Insulation | In what room is it used? | Note |

| Natural materials: rolled jute, felt, insulation made from reeds and sawdust, moss, tow, etc. | Dressing room, rest room. | Natural materials ignite at high temperatures, so they are not suitable for steam rooms and washrooms. But materials made from jute and flax are the best inter-crown insulation for a chopped bath. There are excellent modern roll insulation made from natural materials, but they are very expensive, so they are practically not used for insulating baths. |

| Mineral insulation. | They can insulate any bathhouse. Most often used are easy to install slab insulation(mats). | They do not rot, last up to 30 years, are fire resistant, and inexpensive. Most Russian baths are insulated with these materials. |

| Polymer materials | FORUMHOUSE craftsmen do not recommend it for insulating a steam room. | Polystyrene foam is an excellent heat insulator, but it is flammable, and at high temperatures it releases substances harmful to humans. You cannot use polystyrene foam in the steam room.. Extruded polystyrene foam or penoplex is considered a safe material (it is used to insulate the bathhouse of Russian polar explorers in Antarctica). But FORUMHOUSE experts do not recommend using this material in a steam room. |

| Insulation based aluminum foil. | It is used in accordance with the manufacturer's recommendations for a specific room. | The principle of operation of such insulation is the effect of a thermos, the reflection of heat from the walls and ceiling due to foil. Some types of foil insulation are produced specifically for steam rooms and other rooms with high temperatures, while others begin to release harmful substances when the temperature rises. Foil in the bathhouse is used as a vapor barrier. |

Insulation of the bathhouse ceiling from the inside

The bathhouse is insulated from the inside in the following order: ceiling - walls - floor. The main part of the heat in the bathhouse is lost through the ceiling, so

We hang at least 10 cm of insulation under the black ceiling. I really don’t recommend basalt wool, glass wool and polystyrene foam in the steam room. The insulation can be hung with lacing. Then foil, gap along the slats and lining.

Regardless of the material of the walls of the bathhouse, the ceiling is insulated in the same way.

Insulation of a frame bath from the inside

To insulate a frame bath, rolled mineral insulation is most often used.

To insulate the walls of a frame bath from the inside:

- Insulation is placed in the interbeam space of the structure;

- The next layer is vapor barrier (foil);

- Ventilation gap;

- Sheathing.

The photos below show how I insulated my frame bath Nomad. Insulation – basalt wool.

Insulating a bathhouse from the inside with your own hands: step-by-step instruction.

Foil acts as a vapor barrier, so it is important that there are no even the slightest holes or damage in it, and that all joints are well taped with high-quality tape. The tape is always sold together with foil, and its quality must be checked in the store (glue the tape to the foil and try to tear it off).

Insulating a bathhouse from the inside with your own hands: log house

Insulating a chopped and well-caulked bathhouse from the inside would be a tragic mistake. This is not only pointless and destructive for the walls, it contradicts the very idea of a chopped bathhouse.

Log houses for baths are made for two reasons:

- To get a classic Russian steam bath, which takes a long time to heat and maintains the required level of heat and humidity for a long time. It is the tree that accumulates heat and moisture and gradually “gives it away”. In this case, the inside of the bathhouse cannot be lined; You will also have to come to terms with the high consumption of firewood.

- For the image. No bathhouse looks as cool in appearance as a chopped one. But I often don’t want to waste time and firewood; I want the bathhouse to be heated in an hour, so insulation, vapor barrier and clapboard cladding are done. The log house works only as an external frame; the meaning of the material is lost. In this case, it is cheaper and more correct to build a frame bathhouse.

It happens that a person gets a ready-made bathhouse from a log house, and for various reasons it can be cold. Such a bathhouse can be insulated, but only from the outside.

The pie looks like this:

- insulation;

- wind protection;

- vertical sheathing to create a ventilation gap;

- outer skin.

And you can put foil on the inside and line it with clapboard, not forgetting about the ventilation gap.

- We put foil on the beam and fasten it with a construction stapler;

- We seal ALL joints with foil tape;

- We fill the vertical slats with a thickness of 1-2 cm;

- We fill the lining horizontally, leaving gaps at the top and bottom for air circulation.

If the ceiling of a chopped bathhouse is made of thick boards, it is not necessary to use insulation, but then the following is poured onto the ceiling in a cold attic:

- ash;

- sand;

- expanded clay (it is preferable that the granules be of different sizes);

- clay coating.

Insulation from the inside of a brick bath

Brick is not the best suitable material for the construction of a bathhouse, but if there is a brick factory somewhere nearby, then brick bathhouses begin to grow like mushrooms. Due to the high thermal conductivity of brick, such a bathhouse requires insulation without fail. Insulation is carried out only from the inside, and to make the bathhouse look cool from the outside, decorative jointing is done.

Typically, the pie of an insulated wall of a brick bath looks like this:

- brickwork;

- waterproofing,

- insulation;

- vapor barrier;

- sheathing

Waterproofing between brickwork and insulation is optional: if the walls are built correctly and waterproofed from the foundation, they will not become damp. If there is no confidence in the walls, then it is better to do waterproofing.

The insulation on the brick walls of the bathhouse is attached to the frame.

We build a frame on the wall from 100×40 timber with insulation width increments, fill it with insulation, lay a vapor barrier, sew on 20mm slats and cover it with clapboard.

Our user S4sha’s bathhouse is made of half a brick, but it steams just fine even at -30. Its walls are insulated like this:

- mineral wool;

- vapor barrier (in the steam room - foil);

- ventilation gap;

- lining.

Insulation thickness – 50 mm.

Insulation of a bathhouse made of blocks from the inside

For the construction of a bathhouse, durable and moisture-resistant blocks of expanded clay concrete are preferred. The insulation of such a bathhouse is thought out at the stage of its construction. The most important thing here is to remove the icy mass of concrete from the heating circuit. There is a technology promoted by our user ZYBY, which allows you to solve this problem by constructing a frame-wall from boards with an indentation from the walls of the bathhouse. It is suitable for insulating all baths with stone walls.

To ventilate and dry the space between the frame and the walls, several vents are made in the walls of the bathhouse, at the top and at the bottom outside. The vents are closed while people are steaming in the bathhouse; the rest of the time they are open for drying.

Insulation cake for steam rooms and washing rooms using this technology:

- concrete wall with vents;

- insulation on the frame-wall (with an indentation from the concrete wall);

- frame-wall;

- foil;

- finishing with 50th unedged board (aspen, linden or cedar) to get solid wood in the steam room.

With this approach, there is no need to heat the ice walls. And the insulation will dry out between steaming sessions.

But many owners of a block bathhouse insulate it from the inside traditionally:

- concrete wall;

- insulation (attached to the frame);

- foil;

- ventilation gap;

- lining.

Such a bathhouse needs insulation from the outside as well.

Bathroom floor insulation

Precious bath heat also escapes through the floor, so it also needs to be insulated. To insulate the floor in a bathhouse, it is recommended to use expanded clay as the lightest and most environmentally friendly material.

Expanded clay is poured between layers of concrete floor as follows:

- pour the first layer of concrete;

- wait until it hardens completely;

- expanded clay is poured (layer thickness - 10 cm);

- install reinforced grating.

- pour a layer of concrete;

- make a cement-sand screed.

Summarizing

Good bath - warm bath. And in order for it to warm up well to the required temperature, it is necessary to choose the right thermal insulation and insulate all structural elements.

The bathhouse is also insulated from the inside:

- Windows, doors and all openings - with natural sealants;

- The outer door is made from good natural materials.

At FORUMHOUSE, the issues of insulating a steam room are discussed in detail, and the insulation of the ceiling of a steam room is discussed separately. Find out how to properly insulate a timber bathhouse from the outside. Read our article about insulating the floor in a bathhouse. Get acquainted with the guide to bathhouse constructions of our users and find the answer to any question about arranging a bathhouse. Watch our video on how to build a full-fledged bath complex.

Source: www.forumhouse.ru

We insulate the bathhouse with our own hands

External or internal insulation of the bathhouse is mandatory. This reduces fuel consumption and slows down the cooling process of indoor air. If the structure is not insulated, then it will take several times longer to heat the steam room to the desired temperature.

We insulate the bathhouse with our own hands

Before constructing a building, it is necessary to calculate the means and forces for thermal insulation. It is best if the insulation process begins during construction, more precisely, from laying the foundation.

Basic requirements for materials for bath insulation

Cheap solutions (impregnations, septic tanks) will not fulfill the role of good thermal insulation. Of course, protection from moisture is necessary in any case, but this is a separate task. It is necessary to insulate the bathhouse premises separately, using materials specially created for this purpose. Most attention is usually paid to the inside of the washroom and steam room. The selection of insulation and thermal insulation is done taking into account the rough construction material.

One of the most important requirements for insulation materials is non-toxicity. Because in a bathhouse under the influence of temperatures, toxic materials can easily cause poisoning. Non-hygroscopicity is also important; insulation should under no circumstances absorb moisture.

http://kakpravilnosdelat.ru/kak-uteplit-banyu/

When choosing a specific material, you need to rely on the following characteristics:

- resistance to steam and high temperatures;

- good fire-fighting properties;

- environmental friendliness;

- low hygroscopicity;

- ability to maintain shape for a long period.

Types of insulation for baths

All insulation materials presented on the construction markets are divided into three conditional groups:

- Organic. Natural materials ignite at high temperatures, so steam rooms cannot be insulated with them. They are perfect for a dressing room or rest room.

- Mineral. This suitable remedy for internal insulation of any part of the bathhouse. Time-tested, mineral slabs cannot cause harm because most of their composition is cotton wool. For a steam room, stone wool is the best option.

Stone wool meets all the requirements for insulation for a bath, so it can be used even in a steam room

Of course, 50–60 years ago they used only natural materials that were brought from nearby forests. This is foam, tow or moss. Today these are already partly elite types of insulation; they cost serious money due to the need for them manual collection. Many fans of natural materials insulate their buildings with rolled jute felt or tow. This material can be purchased at construction stores. When it comes to moss, there are conflicting opinions regarding its use. They say that moss is not an ideal material for insulation because it encourages the growth of mold or fungi. However, the moss itself does not have such properties; most likely, the fungus is formed due to improper cutting of a wooden structure or poor ventilation.

How to work with different types of buildings

The installation procedure and the required amount of work depend on the material from which the bathhouse is built.

Insulation of log houses

When working with timber or logs, you need to take into account the drying time, which can be 10 cm or more. Plus, cracks form between the crowns of such buildings, and it blows into them. cold air. It is best to insulate a log house made of round timber or an assembly of timber with jute fiber.

Jute fiber is often cut off at the finish, but these edges can be punched with a hammer and caulk

This material does not rot and has excellent thermal conductivity. Jute itself is a very fragile material, so manufacturers try to add flax fibers to it. But if you already have crumbly material, you can perform classic caulking. This way there will be less work, and the building will probably retain more heat.

If you decide to create a bathhouse from wood, then the insulation is laid during construction. It is better to isolate all problematic parts of the log house in the process.

The work is performed in the following sequence:

- During construction, pieces of jute are laid between logs or beams.

Jute fabric is available in rolls, so it is quite convenient to lay it

Insulation of buildings made of brick or foam blocks

If log houses are insulated using a primitive method, then you will have to work hard with the masonry. And there are more financial investments specifically for working with insulation. Additional thermal insulation is necessary, otherwise a well-heated room will cool down within hours. It’s better to work and invest in materials than to stock up on fuel the rest of the time.

A common and proven method is a suspended ventilated façade. The work process does not take place from the inside, but from the outside of the bathhouse. It is necessary to attach layers of insulation to the walls, and cover the top with siding or clapboard. In the gap between the layers, a space is formed filled with air, thanks to which condensation will not form on the walls and rotting and dampness will not follow.

The width of the frame for the ventilated facade is made larger than the thickness of the insulation, so an air gap is formed inside, preventing the formation of condensation

For a brick building, the following trick is often practiced: a steam room is made of wood inside the room. Brick absorbs heat for a very long time, so it is easier to warm a small steam room naturally if you use a small frame.

A 10x10 beam and sheathing are enough. The process of insulating such an improvised steam room inside a large bathhouse is simple:

- The sheathing is stuffed onto the timber, then stone wool is secured.

- Foil insulation is attached over the layer of cotton wool.

- Lining is most often installed as a finishing layer.

A sheathing is placed on the timber base, stone wool is inserted into it, and then a layer of foil material is attached

You can make it even simpler: do not use timber, but instead immediately attach the insulation to the frame. In this case, an additional layer of waterproofing will be required.

Calculation and selection of materials and tools

We insulate all surfaces of the steam room, wash room and dressing room. And for this you will need:

- Roll paper (for ceiling and walls).

- Beam-rail (5x5, for installing insulation on the ceiling and walls).

- Foil.

- Insulating tape.

- Self-tapping screws.

- Aluminum adhesive tape.

- Insulation calculated according to the area of walls, ceilings and floors.

Tools you will need:

Do-it-yourself insulation of a bathhouse

Any stages of insulation are always carried out according to the golden rule - start from the ceiling and end with the floors.

Ceiling insulation

Before you start working with the ceiling, you need to understand that in the steam room you need 2 times more material. After all, we are not working on a sauna, but on a Russian bathhouse, where the steam should linger as long as possible.

The ceiling is insulated as tightly as possible, preferably before installing the stove

- We cover the entire surface of the ceiling with overlapping roll paper.

- We fix the bars on top of the paper, the insulation will already lie between them.

- Cover it all with foil. It will become a normal, safe insulator. But it is necessary to install foil without saving. It is important that all connections are closed.

The foil layer reflects heat, so the use of such material for a bath is necessary

The tape from the kit must be glued carefully, because it will be very difficult to reuse it

On the ceiling, it is better to lay insulation in two or three layers, overlapping the joints

For a frame bathhouse, it is necessary to put insulation on the ceiling and walls, but for timber and log baths you can do without it. For example, if a bathhouse is made of logs, it is enough to first sew up its ceiling with thick boards - at least 6 cm. Mineral wool is most suitable as insulation for the ceiling - you just need to lay it in a layer of at least 15 cm.

Video: insulation and finishing of the ceiling from the inside

Wall insulation

The best solution for wall insulation is a constructor made from materials that can be easily repaired or replaced.

The structure of the bathhouse wall insulation resembles the structure of a roofing pie

- Slats or beams are vertically fixed to the wall surface. The edges of the lower part must be marked with pieces of electrical tape. A narrow plank is used, not a square beam, because the plank will not be distorted by temperature changes. Before attaching to the wall, panels or boards must be treated with specialized impregnations that are intended for bath rooms.

- The slats will also need foil. They work with it in the same way as when insulating the ceiling. But without this material, the timber will definitely rot, and the insulation will be shoddy. By using foil, you will not need to use vapor barrier films. This material is stapled directly onto the timber. Then everything is pressed with clapboard. But it is important to leave a gap or gap between the lining and the thermal insulation. Usually two centimeters is enough.

- Thermowood racks (lining) are mounted on the fixed slats. The finishing part is filled not vertically, but horizontally. According to observations experienced builders heat loss is so much lower.

Linden lining looks great and retains heat well, and when laid horizontally, heat loss is further reduced

Video: insulation and foil upholstery of a steam room

Bathroom floor insulation

And finally, let's work on the floor. After all, it’s usually through him that he leaves the premises. a large number of heated air. Expanded clay is most often used as insulation for floors - it is an inexpensive and reliable insulation that prevents the formation of mold and condensation.

It’s cheaper, of course, to spill everything with slag, but expanded clay is more environmentally friendly and weighs less. When installing wooden floors, the material is placed between the joists. If a concrete floor is poured, then expanded clay is laid between each concrete layer.

Let's look at the usual cycle of work on insulating a concrete floor.

- First, the initial layer is poured.

- Then wait until it hardens completely.

- Next, expanded clay is poured. A layer of 10 cm is sufficient.

Expanded clay bedding is made between the layers of concrete floor

Video: features of installing a concrete floor in a bathhouse

In addition to walls, floors and ceilings, attention is also paid to the insulation of doors, windows and window openings. They are being processed silicone sealants. External doors are usually insulated with natural materials. And it’s not customary to save on them, otherwise in a few years, or even next season, you’ll have to redo everything.

Source: legkovmeste.ru

Step-by-step instructions: how to insulate a bathhouse from the inside

Insulation is important stage work in the finishing of any private house, but in a bathhouse this operation takes on key importance. A steam room is a room with special conditions, which combines extreme temperatures with high humidity. No matter how well the sauna is built, if careful thermal insulation was not done at the finishing stage, the sauna will not be able to function properly, interior spaces The cold will come in and the heat will go out. To maintain the required temperature indicators, it is necessary to insulate it well. In this matter, you can rely on the professionalism and experience of specialists, or you can insulate the bathhouse from the inside with your own hands. The article provides step-by-step instructions for thermal insulation of a bath room.

What materials are suitable for internal thermal insulation?

Today there are quite a lot of high-quality insulation materials on the market, but not all of them are suitable for bath conditions. To insulate this room, it is necessary to use materials that meet the following requirements:

Today there are quite a lot of high-quality insulation materials on the market, but not all of them are suitable for bath conditions. To insulate this room, it is necessary to use materials that meet the following requirements:

- Non-toxic. In the bath, under the influence of extremely high temperatures, rapid release occurs harmful substances contained in the material, so toxic insulation can cause poisoning.

- Non-hygroscopic. You should select a material that does not absorb moisture.

The insulation for a bath should be:

- resistant to high temperatures and steam;

- fireproof;

- environmentally friendly;

- durable.

There are several groups of insulation materials that can be used in a bathhouse:

- Organic. These are natural materials that can ignite from high temperatures, so they only insulate the rest room and dressing room.

- Mineral. These materials are suitable for insulating the steam room and any other parts of the bathhouse.

In accordance with the above requirements, the best heat insulators for a bath are described in the table:

| Name of material | Main characteristics |

| Mineral wool | The structure of the insulation consists of randomly arranged fibers. The material is non-toxic, practically does not absorb moisture, and is lightweight. Suitable for insulating walls, ceilings and wooden floors of bathhouses. |

| Extruded polystyrene foam | The structure is closed cells. Has high strength and compression resistance. Does not contain harmful components. Can be used to insulate concrete floors. |

| Expanded clay | It is a porous granule that does not allow moisture to pass through. Very light and durable, contains no toxic substances. Used for thermal insulation of ceilings and floors. |

Foil slabs of mineral wool, as in the photo, are well suited for insulating a steam room, as they work on the principle of a thermos, retaining heat indoors for a long time. To create an airtight coating, the mats are fastened together with foil tape.

Foil slabs of mineral wool, as in the photo, are well suited for insulating a steam room, as they work on the principle of a thermos, retaining heat indoors for a long time. To create an airtight coating, the mats are fastened together with foil tape.

If insulation is carried out with a material that does not have a foil layer, it must be covered with a water vapor barrier film.

When using mineral wool for thermal insulation of the floor, it is necessary to make multi-layer insulation. It is best to put expanded clay as the first layer, which is not attractive to rodents.

Insulation of the bathhouse needs to be done not only inside, but also outside the house. We described earlier how to properly make external insulation in the article “Thermal insulation of a bathhouse inside and outside - technologies and materials.” Below we will discuss in detail how to insulate a bathhouse from the inside with your own hands. The process consists of several successive stages.

Floor insulation

Work on internal insulation is carried out in the following sequence:

Work on internal insulation is carried out in the following sequence:

- Leads to the bathhouse a drain pipe, which is usually installed in the center of the room.

- Roofing material is laid on well-compacted soil, which will prevent moisture from entering the insulating pie from the soil. The edges of the material must extend onto the walls to a height of at least 15 cm.

- Almost the entire space under the bathhouse is covered with a thick layer of expanded clay or slag. For ventilation, leave 20-25 cm between the top edge of the backfill and the floor beams.

- Floor beams, pre-treated with an antiseptic compound, are installed on protruding sections of the foundation.

- Skull blocks are screwed to the bottom of the beams, then a subfloor is laid on them.

- The entire structure is covered with a vapor-proof film so that both the subfloor boards and wooden beams are covered.

- Mineral wool slabs are laid on the film between the beams or granulated expanded clay is poured.

- The heat insulator is also covered with film on top.

- Logs are installed across the beams, then wooden flooring is laid on them. In the place of drainage in boards they make round hole for water drainage.

- Slats are nailed on top of the boards, which will serve as lathing for installing a waterproof floor.

- Insulation is placed between the frame slats, the foil layer should face upwards. The plates are connected to each other using foil tape. To insulate the pipe, it is also wrapped in thermal insulation material.

- A finished wooden floor is laid on top of the insulation.

Wall insulation

Log bathhouse

Insulation of bath walls

Wood has low thermal conductivity, and walls made of logs themselves perfectly retain heat inside the log house, provided that the caulking of the inter-crown joints is done well. Therefore, there is no need to make a multi-layer wall cake; to eliminate heat loss, it is enough to lay one layer of insulation 50-80 mm thick.

Thermal insulation of walls is done as follows:

- Basalt mineral wool slabs are laid directly on the wall and secured with mushroom fasteners; the foil layer should face the room. Because the log wall uneven, natural ventilation gaps will form between the insulation and the wood, which will prevent the accumulation of condensation.

- A wooden sheathing is mounted on top of the mineral wool.

- The wall is sheathed with 10 mm thick clapboard, which is attached to the sheathing slats.

Baths made of timber

Thermal insulation of timber bath walls

A log house, just like a log house, is first caulked and then additional insulation. Walls made of timber are smooth and it is much easier to attach insulation to them.

Sequence of work:

- A frame of wooden slats is mounted on the wall, which are installed at a distance of 60 cm from each other.

- Mineral wool mats are laid between the sheathing bars.

- The entire structure is completely covered with rolled foil material, which is attached to the frame slats. The joints between the canvases are taped with foil tape.

- A counter-lattice is made, the slats are nailed to the frame bars. This creates an air gap between the insulating material and the finishing material.

- The lining is being installed.

How to properly insulate a door

Door insulation technology

Large heat losses occur through door cracks, so you must take care of the thermal insulation of wooden or iron door leading to the bathhouse.

Felt, basalt wool, and foil insulation can be used as insulation. There are several ways to insulate a door; below we present the most common:

- A frame of 15x20 mm slats is mounted around the perimeter of the door, which should recede from the edge door leaf by 10 cm.

- A piece of hardboard is placed inside the frame and stapled.

- Felt or other material is pulled over the top of the frame and secured with nails, which should be 5 cm larger than the frame itself.

Ceiling insulation

Thermal insulation of the ceiling in a bathhouse without an attic is done from the inside; if there is an attic, it can be insulated both inside and outside the room. Don't forget to also insulate the chimney. If it is made of a sandwich pipe, inside of which there is an insulating layer, such thermal insulation will be quite sufficient.

If the chimney is made of one pipe, it must be wrapped with basalt insulation, and a larger diameter pipe must be placed on top.

Insulation of the ceiling structure can be done in three ways.

false ceiling

The thermal insulation of such a ceiling is very similar to the insulation of walls. The attic floor beams act as a frame for the sheathing flow.

- From the attic side, a layer of waterproofing is laid on the beams, and then boards are laid.

- Insulation boards are tightly laid between the beams from the inside of the bathhouse.

- The insulation is covered with a vapor barrier film or foil material, which is attached to the beams themselves.

- The ceiling is covered with clapboard.

Panel ceiling

This ceiling consists of special panels with inside which already have a layer of insulation and vapor barrier. Typically, mineral wool 10 cm thick is used.

The ceiling panels are assembled at the bottom and then in finished form go up. However, the panels are quite heavy, and it is quite difficult to lift such a structure yourself. Therefore, they are usually lifted in parts and mounted at height.

After installing and securing the panels, pads of insulating material are laid between them and the main ceiling.

Flat ceiling

This ceiling is distinguished by the absence of floor beams. It consists of boards 50 mm thick, which are placed directly on the walls of the bathhouse or on bars nailed along the perimeter of the room at a distance of 10-12 cm below the ceiling.

This ceiling is distinguished by the absence of floor beams. It consists of boards 50 mm thick, which are placed directly on the walls of the bathhouse or on bars nailed along the perimeter of the room at a distance of 10-12 cm below the ceiling.

Thermal insulation in this way is suitable for small rooms no wider than 2.5 m. In this case, only thin insulation with a thickness of no more than 5 mm can be used.

The following insulation scheme is used:

- The boards are covered with a vapor barrier film.

- Insulation is placed on top.

- Then comes a layer of waterproofing.

- Everything is covered with sheets of plywood or boards.

Using the instructions for internal insulation of a bathhouse, you can independently make thermal insulation of not only new but also old buildings. But before insulating an old building, it is necessary to carefully prepare the walls, seal cracks and cracks, treat the wood with an antiseptic, and only then begin thermal insulation.

If you decide to convert a change house or trailer into a bathhouse, then their insulation can also be carried out according to the given scheme.

The Master Srubov company has been professionally providing finishing and thermal insulation for many years. wooden houses in Moscow and the region. If you want your bathhouse to delight you with warmth and comfort, to serve you well, and to maintain optimal temperature conditions in the steam room, we are ready to help you with this.

You will find our coordinates in the “Contacts” section.

Calculate the cost of painting and insulating your home right now

Every modern building for couples procedures should have effective thermal insulation. After completing this procedure, the premises are heated in a short time. You can create a layer of insulation in a bathhouse with your own hands. Any owner of a building can, with little effort and time, create an insulating layer from modern material, without the help of specialists.

Insulate your sauna to create a more comfortable atmosphere

Benefits of the procedure

If the task is to thermally insulate a bathhouse from the inside with your own hands, you should first find out how to insulate this structure correctly. This will avoid many mistakes. This method, according to experts, is the most reliable. It allows:

- Increase the service life of premises.

- Eliminate the need for frequent bath repairs.

After creating a layer of insulation from mineral wool or polystyrene foam, the consumption of solid fuel when heating rooms is reduced. If used during an event modern materials, then a comfortable atmosphere arises in the washroom and other rooms.

In this video we will learn about the process of insulating a bathhouse:

Very rarely, a bathhouse on a country site is a log house with a traditional brick stove inside. Most often this building frame type made of wood or a building made of concrete. To quickly warm up rooms, you cannot do without an insulating layer. If you refuse to create it, the rooms will cool down in a short time.

The thermal insulation procedure for a bath has certain advantages. Experts identify the following as the main ones:

- Proper insulation of the steam compartment provides an opportunity to save resources. Optimal temperature in a steam room occurs in a short period.

- If the event is carried out correctly in the dressing room and in the shower, the owner will not worry about the uncomfortable atmosphere in these rooms when receiving couple procedures.

- If we exclude deviations from the technology when creating an insulating layer, then when further use construction, the circulation of moisture and steam inside the bath will occur in the correct way. As a result, they will be prevented from settling on the facing material and on the walls. It means that wooden elements the structures will not rot.

It should be said that you should not use a bathhouse for its intended purpose if there is fungus or mold on the walls. This negatively affects your health and can lead to asthma. In addition to this, walls with such decoration look unattractive.

Material requirements

To create an effective insulating layer, it is necessary to use modern materials with excellent performance characteristics. When performing work on thermal insulation of surfaces, most specialists pay attention to the washing room and the steam room.

The insulation should not be toxic. During the operation of the building, the insulating layer is constantly exposed to high temperatures. If the material is toxic, then under the influence of this factor it will begin to emit fumes. They can provoke poisoning of people taking paired procedures.

Low hygroscopicity is another quality that a heat insulator intended for a bath should have. Moisture is a factor that negatively affects most insulation materials. Therefore, when searching for a material, you should use one that is insensitive to its effects. Having chosen a product with the desired characteristics, the owner will not be faced with the need to replace the insulation layer ahead of time.

There are a number of properties that should be taken into account when choosing insulation. The most important are:

- Resistant to high temperatures and steam.

- Excellent fire-fighting properties.

- Ability to maintain shape for a long time.

Based on these parameters, you can select an effective material. Carrying out the procedure using it will ensure high-quality insulation. Typically, mineral wool is used to insulate a bath. She happens to be best choice in terms of price and quality characteristics.

Types of insulation

Today, selecting a material for thermal insulation of a bathhouse is not an easy task. There are many solutions on the market for creating an insulating layer. All of them variety can be divided into three groups:

- Organic. This may include products for natural basis. Its disadvantage is that it is highly flammable at high temperatures. Therefore, when carrying out work in a steam room, such insulation cannot be used. They are an excellent choice for creating an insulating layer in a waiting room or rest room.

- Mineral. These solutions can be considered as good option for insulating the bathhouse from the inside, and any part of it. Mineral wool slabs, which have proven their effectiveness, do not cause any harm to health. They are made from natural raw materials, therefore they are environmentally friendly material. In the steam room, it is best to use stone wool. Its main advantage is that it does not support combustion. It fully complies with all the requirements for thermal insulation materials for baths.

When choosing insulation for a bath, remember their harmful effects on human health

When choosing insulation for a bath, remember their harmful effects on human health - Chemical. This usually includes products that are made from plastic. When insulating a bathhouse, their use is permissible. In order not to harm your own health, during work you need to think about creating a reliable exterior decoration. In this case, harmful fumes will not penetrate into the premises of the building.

Materials such as tow and moss can now be easily purchased in specialized stores. However, these heat insulators are elite. Therefore, their price is high. To install high-quality and environmentally friendly insulation, it is best to purchase jute felt, which is offered in rolls.

There are many controversial opinions regarding the use of moss for thermal insulation. Some experts say that this material is not entirely suitable for insulation, since fungus and mold easily develop in it.

But in reality it does not have such properties. Most likely, the development of such unpleasant phenomena is associated with an incorrect method of cutting the structure or with violations made during the installation of the ventilation system in the bathhouse.

When carrying out the bath insulation procedure Special attention should be paid to the material from which it is made. This point influences the progress of work, as well as the choice of a suitable thermal insulation solution. The solutions used for the construction of baths are quite diverse. They differ in characteristics.

If the task arises of thermal insulation of a log bathhouse made of timber or logs, then it is necessary to take into account their shrinkage, which can be up to 10 cm. In addition, in such buildings, gaps appear between the crowns. It is through them that cold air flows are blown in.

The best option for insulating such buildings is to use jute fiber. Its advantages: does not rot and has excellent thermal conductivity.

When insulating log houses, a primitive method is usually used. If the building is built from modern materials, for example, foam blocks, then it is necessary to spend a lot of time to create a high-quality layer of thermal insulation.

An additional insulating layer in brick buildings or bathhouses built from foam blocks is very important. If it is missing, then after heating to the desired temperature, the heat will leave the bathhouse rooms in a few hours.

During the procedure, it is best to use modern materials with high performance characteristics. Usually a ventilated façade is installed on the walls. After fixing, the insulation boards are sheathed using modern decorative solutions: lining, siding. An air space is formed between these two layers. It rids the walls of condensation. This means that the owner will never encounter dampness on the façade.

Work technology

To quickly warm up a structure, thermal insulation of not only the walls, but also the ceiling surface is of great importance. Insulating a bathhouse from the inside with your own hands is a very simple undertaking. But despite this, you should be aware of some nuances. One of them: in order for the thermal insulation of the bathhouse from the inside to be effective and last a long time, it is necessary to install a layer of vapor barrier.

Lathing and laying insulation

The first stage of the insulation procedure is the creation of the sheathing. In addition to conventional slats, you can use galvanized profiles. When carrying out work, it must be remembered that the distance from the sheathing to the base of the wall should be slightly greater than the thickness of the insulation used. This can be achieved by placing pieces of timber under the slats.

Next, the insulation for the bathhouse is laid on the walls from the inside. An inner layer of basalt wool slabs is usually placed between the bars. When carrying out work, it is necessary to work in a respirator. If there is no such means of protection, then you can get by with a gauze bandage. Special glasses should be used to protect your eyes. The fibers in the structure of this material are small and very volatile. They easily enter the human mucosa and cause irritation.

To cut mats into blanks required length, you can use a regular sharp knife. When laying, do not jam the heat insulator. Optimal choice is a high density material. It provides maximum efficiency insulation.

Steam protection device

The next step is a steam protection device. The film strips should be fixed in a horizontal orientation in the direction from bottom to top with an overlap of no more than 5 cm. The method for placing the vapor barrier is largely determined by the material from which the sheathing is made.

If it is made of wooden slats, then it is necessary to fix the protective layer using staples and a construction stapler.

If the structure is made of galvanized profile, then the best solution There will be aluminum tape to secure the material. In order for the protection against steam to be as effective as possible, you should not only secure the heat insulation boards well, but also glue the resulting joints with tape. In this case, moisture will not penetrate into the insulation.

Creating a Facing Layer

For device decorative covering usually clapboard is used. To make the room feel cozy, you need to use high-quality material.

First you need to take care of the preparation necessary tools. During work you will need:

- Circular Saw. As an alternative, you can use an electric jigsaw.

- Drill-driver.

- Rasp. It is necessary when you need to adjust and process the edges of the lining.

- Level and plumb.

- Metal clamps. These elements are used to fix wooden panels;

- Copper or galvanized screws. They are used for attaching clamps to bars;

- Self-tapping screws for metal;

- Wooden skirting boards for finishing corners.

During work on the installation of the facing layer, fixing the lining panels, it is necessary to create a small gap between the material and the waterproofing layer. Along the edges of the ceiling, in the upper and lower parts of the walls, it is worth creating gaps of no more than 2 cm. To secure the outer boards, it is necessary to fasten them through each row with screws. The caps will be easily covered by the laid plinth. Other boards will be held using clamps.

Insulating a bathhouse is a necessary procedure to reduce the cost of its operation. It is mandatory, even if there is an old facility for paired procedures on the site. Every owner is capable of holding a quality event. In order for the end result to please you, it is necessary to use modern insulation for the walls inside the bathhouse and not deviate from the technology of work. Then, upon completion of the work, the bathhouse will warm up well. The heat will not leave it for hours.

The secret of creation comfortable place for bath procedures is difficult to describe in one phrase. It consists of many components, one of which is maximizing the thermal efficiency of enclosing structures, that is, insulating the bathhouse from the inside or outside. This is a critical construction stage that requires the contractor to be technologically literate and careful, which is worth taking into account when planning to do everything yourself. At the same time, the results of high-quality implementation of thermal insulation measures not only have a positive effect on the comfortable use of the structure. There are also a number of related aspects that you should know before you start planning your practical actions.

What does insulation do?

Many developers or planners major repairs their real estate, setting themselves the task of being well insulated, they do not have a complete picture of the upcoming actions and their consequences. Let's look at examples of what we actually get if the thermal insulation of a bathhouse is installed in compliance with the technological map of this construction stage:

- First of all, of course, comfort. In the interior spaces of such a structure, it is easy to maintain the required temperature and humidity conditions, that is, to ensure the stability of a specific bath microclimate. In practice, this means the absence of drafts in the rest room or washing room, caused by supercooling of air masses near rapidly cooling enclosing structures. In the steam room, the human body will warm up evenly from all sides, fanned warm air, caressed by infrared rays emanating from surrounding surfaces.

- Economic profitability of operation by increasing the efficiency of using energy generated by a heat generator (furnace or boiler). It is expressed in direct material savings associated with a reduction in purchasing costs for fuel. If we make a rough comparison, then if the bathhouse is well insulated, its heating will require half as much energy resources. In addition, preparing the steam room for procedures will be possible in the shortest possible time.

- Safety building structures and a healthy indoor microclimate. This is important for buildings assembled from any type of materials. However, bath insulation, together with reliable vapor barrier, is of particular relevance for structures made of wood materials. Indeed, in addition to the fact that the air cooled near the external surfaces forms unpleasant air currents, a large amount of moisture condenses from it. Liquid that regularly collects on supporting structures, inside thermal insulation or under decorative cladding becomes a favorable environment for the development of microorganisms. The result is decay building materials, pollution of the bathhouse atmosphere with their decay products and mold spores.

When is internal insulation preferable?

There are many opinions about how to insulate a bathhouse - from the inside or the outside. At the same time, you need to understand that the problem being solved differs from the arrangement of thermal insulation for other buildings, since for them it is recommended in all possible cases to give preference to external thermal screens. However, the specific microclimate of bathhouses exposes construction and finishing materials to almost extreme influences: humidity up to 100% () and temperatures up to 110-120 0 C (in saunas), and on individual surfaces up to 160 0 C. Therefore, the insulation of a bathhouse from the inside is intended to provide not only preservation of the desired thermophysical parameters, but also to eliminate the impact of aggressive factors on the building envelope.

It is also possible to create a heat and vapor barrier from the inside to complement external thermal protection. In this case, the internal barrier layers will serve more for protection structural elements buildings from direct exposure to moisture and high temperatures.

Methods and materials

A modern developer, on the one hand, has a noticeable advantage over his ancestors, since he has a huge choice of how and with what to insulate a bathhouse, and on the other hand, the wealth of alternatives presupposes a clear understanding technological features use of certain materials.

What used to insulate baths?

In the old days, a person learned to make do with what was given to him environment. Application technologies natural materials for building thermal protection have been developed for centuries and continue still in use today, as they are distinguished by their availability, environmental friendliness and low cost. Of course, taking into account the fact that the walls were built from thick logs - a material with good thermal efficiency, the thermal insulation of the bathhouse largely came down to ensuring the tightness of the butt joints. It was achieved by laying inter-crown insulation from moss or flax strands, even at the stage of construction, as well as subsequent internal and external caulking of the seams.

Log ceilings were coated with clay, and later they began to use sawdust or straw between the load-bearing beams. At the same time, the inner layer of steam and thermal protection was always made of coatings based on clay or its mixtures, for example, with chopped straw. Already in the 20th century, granulated expanded clay became widespread, which differed favorably from organic natural materials in that it is absolutely non-flammable, does not rot, and is also not afraid of rodents. Insulating a bathhouse with porous ceramic granules has only one drawback - the layer of them must be 2 times thicker than that of sawdust or straw.

As for the floors, they were made of a leaking type, where water flowed through the cracks between the flooring boards into a ground absorption pit. It was quite difficult to arrange thermal protection for such a design in practice. To some extent, a similar problem could be solved by organizing a ventilated space between the flooring and the ground.

How are baths now insulated?

Adherents of authenticity can still choose to insulate a bathhouse from the inside using only natural materials. However, despite the environmental advantages of natural raw materials, by themselves they can no longer provide a number of parameters with which the concept of “modern development” is associated. For example, it does not have sufficient durability, stability of properties, and does not guarantee the creation of the required level of comfort and thermal insulation. Therefore, natural materials for thermal protection are rarely found in their pure form, and products based on their processing or completely synthetic products are mainly used. However, modern insulation for a bath from the inside:

- must meet environmental factors, especially taking into account the extreme conditions specified for its operation;

- meet efficiency requirements, that is, have the lowest possible thermal conductivity coefficient. Today, such values are considered to be close to 0.03-0.04 W/m*K.

Mineral fiber wool

The most popular raw material for creating thermal barriers in rooms with any operating microclimate, and is ideally suited for bathhouse buildings. The starting material is of mineral origin and has no harmful secretions at any temperature, not afraid of fire, not rotting and not subject to gradual chemical decomposition, like most polymers.

Important! When planning to insulate a bathhouse from the inside with your own hands, you need to take into account that cotton wool is different. Ignorant use of it can give the opposite thermal effect, accelerated destruction of enclosing structures and deterioration of the quality of the indoor microclimate.

Firstly, wool based on staple glass fiber, like its previous analogue - slag wool, is quite soft material, which requires increased attention to its consolidation. For example, on walls with a high layer height, it will slide, gradually exposing sections of the structure. Therefore, it is recommended to lay glass wool on walls in low spans horizontal sheathing, use on ceilings, and generally exclude it for floors under screed.

Secondly, insulating a bathhouse from the inside using wool made from stone (basalt) fibers has one significant operational disadvantage. Although the fiber raw material itself is absolutely harmless to humans, the problem with using products made from it lies in the binding resins with which the finished product is impregnated. Knitting components, of course, make it possible to create mats that are resistant to mechanical stress of varying intensity and convenient for laying in guide frames or even under floor coverings. However, this same binder, when used at high temperatures in a steam room, begins to release a toxic phenol-formaldehyde mixture. Therefore, it is better to organize the insulation of a steam room from the inside using glass wool, but basalt wool is perfect for other rooms.

Styrofoam

Affordable material also attracts many simplicity of its installation. However, its use specifically in the internal space of the bathhouse is a big question. You can immediately exclude it installation in a steam room or furnace, since none of the polymers are designed for use at temperatures above 60 0 For environmental reasons. In addition, it is undesirable to insulate a bathhouse from the inside using it for wooden buildings, since foam sheets have extremely low vapor permeability, “do not breathe,” and spots of rot can form at the point of contact with wood.

The use of high-density foam sheets from ordinary or extruded raw materials is quite justified for thermal insulation of floors under screed.

Ecowool

Quite a promising heat-shielding material, gradually gaining more and more popularity. It is absolutely safe for humans under any conditions of use. Therefore, if you are planning to insulate the walls in a bathhouse from the inside with your own hands, then this will be an excellent choice. Ecowool will also fit well on ceilings, but for floors, without creating load-bearing frames, it is of little use, as it easily wrinkles, losing its thermal insulation properties.

The material is produced from recycled materials: waste paper, waste or discards from the production of corrugated packaging, cardboard or other pulp and paper products, while maintaining all the environmental benefits of shredded paper. Thanks to antiseptic treatment ( boric acid) ecowool is not afraid of moisture, however, like mineral wool, it needs to create conditions for free ventilation. In order to improve the fire-fighting properties, the flakes of the finished product are impregnated with a fire retardant (sodium tetraborate). As a result, they do not support combustion and smolder with self-extinguishing.

It should be borne in mind that insulating a bathhouse from the inside with your own hands will only be possible using the dry method - pouring material into prepared niches or pockets. This poses some challenges to widespread use of the technology. There is a more practical wet method that allows you to distribute ecowool over any surface, but it requires the involvement of specialized specialists using inflatable pneumatic equipment.

Expanded clay

Although it is not one of the types of thermal insulators with the highest thermal resistance - its thermal conductivity coefficient at a density of 200 kg/m3 is 0.1 W/m*K, and at a density of 800 kg/m3 - 0.18 W/m*K - continues successfully compete with more efficient modern materials.

In today's construction, insulating a bathhouse from the inside using expanded clay is perhaps best suited for arranging floors. Of course, it will have to be poured in a layer 3-4 times thicker than for polystyrene foam or mineral wool. But this is not so significant, since we are talking about floors, where it is possible to create the necessary reserve for the height of the backfill, and the load on the supporting structures is not considered at all.

The advantages of expanded clay have already been mentioned above; all that remains is to add that it is completely safe for humans. It can be recommended for thermal protection of floors in all rooms of the bathhouse, including steam rooms and washing rooms.

Nuances of practical implementation

Having weighed all the pros and cons regarding the selected materials, before starting work, it is necessary to analyze the technological aspects of how to properly insulate a bathhouse from the inside. Otherwise, even vaunted products will be useless in the hands of an incompetent installer. From the most popular types of thermal insulation described above, we can already conclude that each of them is preferably used on certain building elements of the structure. Let's consider, for example, the option of installing mineral wool on the ceiling and walls, and expanded clay backfill for thermal protection of floors.

Floor

If previously they were made of a leaking type, which made it difficult to insulate them, now such structures are found in the most simplified or temporary buildings. Man's desire for comfort has led to the appearance of non-leaking floors, because without them it is impossible to fully insulate a bathhouse from the inside.