If you are planning to equip your Vacation home autonomous water supply and acquire a well, then you need to familiarize yourself with the technology of drilling. This will save a lot of time when looking for drillers and funds during the drilling process itself.

Types of drilling technologies

When installing a water supply system in a private house, as a rule, one of three drilling technologies is used:

- Rotary;

- screw;

- Shock-rope.

The difference between these technologies lies in the methods of destruction of the rock inside the well, as well as in the methods of extracting the soil to the surface. Naturally, depending on the technology, the set of necessary equipment also depends.

Why does the customer need to know these technologies? This will give an understanding of how the well will be drilled, what equipment will be used for this and how long it will take. In addition, the price of work, as well as the quality of the final result, depends on the type of technology.

In the photo - auger drilling

screw method

The cheapest and simple option is auger drilling. Therefore, most of the small-sized drilling rigs are based on this technology. It is based on the usual Archimedean screw (auger), which is used to extract soil to the surface.

To make it easier to imagine this method, one should remember how fishermen drill a hole in the ice. In this way, wells can be drilled with a depth not exceeding 10 meters.

A feature of this method is the possibility of making a hole only in relatively dry and soft soils. If at depth they are hard rocks or quicksand, then it is impossible to perform further work in the auger way.

I must say that the technology of drilling wells under water with an auger is usually used by private "drillers" who have small installations. As a rule, it is not difficult to find organizations that provide such services.

Note!

To perform a well, it is not enough just to drill a hole in the ground.

It is also necessary to protect the aquifer well from perched water, as required by the instructions.

Therefore, despite the fact that the process itself is not difficult, the qualifications of the performers are very important.

rotary method

The technology of drilling a well under water in a rotary way, today, is the most common. To make a hole in the ground in this way, a drill pipe is used, inside of which there is a rotating shaft with a chisel at the end.

The load on the tip is transferred by a hydraulic installation. This method is attractive in that it allows drilling to almost any depth, regardless of the type of rock.

The soil is washed out by constantly flushing the well with drilling mud.

The solution can be supplied in two ways:

- The pump inside the drill pipe, in this case, the soil with the solution goes by gravity into the annulus.

- By gravity into the annulus, while the solution with the rock is pumped out of the drill pipe forcibly.

I must say that the second method, which is called backwashing, is better to open the aquifer, so that the well will have a greater debit. However, this method is more laborious and requires more sophisticated equipment, and, accordingly, is much more expensive.

Therefore, the choice of technology depends, in this case, on your budget and required amount water. As a rule, if it is necessary to provide water to one household, then drilling with direct flushing is quite sufficient.

Now consider this technology step by step:

- First of all, the chisel penetrates into the ground large diameter.

- The bit is then rotated by the impact of the rotor, which is driven by the motor.

- Weighted pipes are installed between the drill pipes and the bit, which add additional load.

- During operation, the soil is removed by the pressure of the fluid from the mud pump.

- Having completed the drilling of the first section of the soil, a casing pipe is inserted into the well so that the upper layers of the soil do not fall inside the well.

- For stability, the space between the soil and the first casing is filled with mortar.

- Drilling then continues with a smaller bit, after which a narrower casing is inserted.

Related articles:

Shock-rope method

This water well drilling technology is the oldest, slowest and most labor intensive. However, the quality of such work is the highest. Its essence lies in the fact that the rock is destroyed by crushing with a powerful heavy projectile, which first rises to a certain height, after which it drops sharply.

As a result, the projectile destroys the ground with its weight, which is multiplied by the free fall coefficient. The destroyed rock is removed from the trunk with the help of a bailer. If the ground is soft, then, as a rule, the bailer and chisel are combined into one projectile.

The main advantage of such drilling is that it does not require the use of drilling fluid or water. Thanks to this, it is possible to open the aquifer more accurately and thereby ensure the maximum long term well service and the maximum possible debit. As a rule, wells made in this way serve more than 50 years.

The main disadvantage of this technology, for the customer, is the high cost of services. In addition to the fact that this method is laborious in itself, in the process of work it becomes necessary to isolate all the upstream aquifers. In other words, how many aquifers and quicksands are in the well, so much casing pipes must be used, and these are additional costs for material and work of specialists.

Which technology to prioritize

In reality, the choice of the customer is not so much, especially if the conditions on the site do not allow the use of an auger. The impact-contact method has been almost completely replaced from the market by rotary drilling, which, most likely, will have to be used.

However, it is necessary to take an interest in technology at least in order to determine the adequacy of the cost of services. If the soil conditions are suitable and the aquifer is not deep, then it is much more profitable to use the auger method.

Is it possible to drill a well yourself

It is quite possible to break a well with your own hands, the only question is how much time and effort it will take you, and also how well it will be possible to isolate the trunk from the upper aquifers.

Often, developers underestimate the complexity of the work, as a result of which either “water from a puddle” is obtained from a great depth, or specialists finish the work. At the same time, drillers have to pay almost the full cost, as if they were doing the work from scratch.

Therefore, before deciding on self-fulfillment work, you need:

- To study drilling technology in detail;

- Understand what equipment you need Consumables;

- Make sure that your area can be drilled with a small-sized drilling rig.

Small-sized installations are of two types:

- Screw type - as a rule, these installations are self-made.

- Shock-rope type - installations can have Electrical engine or an internal combustion power unit. This is important if there is no electricity on the site.

Advice!

Less demanding on the ground and simpler is the installation for drilling with a shock-rope method.

With its help, you can drill a well in almost any soil.

Conclusion

All existing well drilling technologies are fundamentally different from each other, however, if professionals are involved in the work, then each of them allows you to achieve the desired result. At the same time, one or another technology should be preferred in accordance with one's own financial capabilities, soil conditions and the depth of the aquifer.

For more information on this topic, see the video in this article.

A well for water production is a rather complex structure. Many today are interested in drilling wells for water: process technology, tools and equipment for performing work. The quality of water from a well or well depends on their design. The service life depends on the quality of the work performed.

How to drill a water well

Before drilling a well for water, it is necessary to choose a place for it. It must be a piece of land approximate dimensions 4x12 m. If the house has not yet been built, then it is better to choose a place in the future basement. If the house has already been built, then it is better to drill closer to the foundation. To the place of work, it is necessary to ensure the passage of the drilling rig and the water carrier. At a distance of approximately 2 m from the location of the drill, there should be no electrical wires. Such measures are required general rules drilling wells under water.

There are several drilling methods. But with any of them, the following operations must be performed:

- rock grinding;

- excavation of crushed earth outside;

- strengthening of the walls of the well.

How is rock crushing done? This is done with the help of special rock cutting devices. It can be explosive energy, electrical or thermal. But all these types are used quite rarely. Much more often they use others: augers, glasses, hand drills.

The soil is taken out in the following ways:

- hydraulic;

- mechanical;

- pneumatic;

- combined.

The hydraulic method is carried out with water, a solution of clay or other technical fluid. Mechanical - with the use of special drills, screws, bailers. With the pneumatic method, the crushed rock is removed by a strong jet of compressed air. With the combined method, several of these methods are used.

The technology recommends fastening the walls of the well to water with metal casing pipes. Most often, these are seamless pipes on a threaded or welded joint. Occasionally, other options are also used. But it is not recommended to use stainless steel(very expensive!) and galvanized metal.

When drilling a well for water, flushing is often used. This is a method in which water is supplied to the well using pumps. She then, together with the crushed rock, rises and settles in a special sump. According to the settled rock, drillers determine the section of the site. The water then makes a new circle. The rising clay solution strengthens the walls and prevents them from collapsing.

The process of drilling a well involves its sequential casing with pipes. The drilling of wells for water is completed by pumping them, which is carried out until a completely transparent liquid flows.

Water drilling methods

The technology of drilling a well under water allows you to work in several ways:

- auger;

- rotary;

- shock-rope;

- manual.

Let's consider each of them in more detail.

Auger drilling is the most common and affordable way. The auger in the form of a screw enters the soil and loosens it. Only dry and soft ground can be drilled. Augers are completely unsuitable for quicksand. This tool destroys the rock and lifts it into the wellhead. Screws are available in diameters from 60 to 800 mm. They can be drilled to a depth of 60 m, sometimes up to 100 m. Auger drilling is impossible on rocky soils.

The rotary method is continuous action tool called a rotor. It is constantly spinning. The rock is washed out with a clay solution. This method is relatively cheap and fast enough. But in cold weather it requires insulation of the system through which water circulates. Drilling is carried out using machines:

- URB-2A2;

- MBU-2M;

- URB-2.5;

- URB-3AM.

URB-2A2 is capable of drilling soil up to a depth of 55 m, URB-2.5 - up to 300 m, and URB-3AM - up to 500 m.

The shock-rope method is the most labor-intensive. But it should not be forgotten, as it is of the highest quality. The rock is destroyed after hitting a heavy object. This is a specially shaped pointed glass made of steel pipe. It falls from a height, hits the ground, picks up the destroyed soil and rises. At the top, the glass is cleaned and thrown down again.

The drilling rig itself can be made by hand from pipes or from logs in the form of a triangular cone. This cone is equipped with a cable winch. The technology of drilling wells for water does not require the use of mud. But the installation of casing pipes must be carried out in a timely manner. Such an installation can drill a diameter of 10-30 cm. But the depth cannot exceed 10 m. For drilling, you can use the UKS-22M2, UGB-50, UGB-1VS installations.

The manual method is used quite often. With it, driven pipes or augers are used. The pipes are cut into pieces about 2-3 m long. An external thread is cut at their ends. A tip is welded onto the lower end of the pipe. It has the form of a cone, the diameter of which is 1 cm larger diameter pipes. Above the tip of 60-100 cm, the pipes are drilled through 5 cm with a drill with a diameter of 6 mm. It will be a kind of filter. As the pipe deepens, it lengthens with the help of couplings. But it's easier to do it the other way. You need to prepare for work:

- various drills;

- rods;

- casing pipes;

- winch;

- drilling rig.

If the well is not very deep, there is no need for a tower. The work process is quite simple. You need to dig a hole about 50 cm deep, install a drill and start rotating it. It's better to work together. Every 50 cm, the drill is taken out of the ground and cleaned. This method is cheaper than the others, but has limitations in depth.

Conclusion

The technology of drilling wells for water involves the destruction of rock, cleaning the shaft, strengthening the walls and the final equipment of the well with pipes, filters, pumps and taps for taking drinking water. The process of drilling a well can be different. Deep pits are performed using rotary drilling technology. Often use auger drilling: its technology is quite simple and is used in personal areas. With a screw speed of 250 rpm, the whole process is quite fast.

Casing is used for any well drilling technology special pipes to protect walls from collapse and penetration dirty water from the upper aquifers.

Shallow wells can be obtained by the shock-rope method. The manual method works well. Any drilling ends with the closing of the top of the aquifer with a special tip. The necessary wires, hoses and pipes are passed through it to deliver water to the house.

Get to aquifers and finding water sources is not an easy task and technologically very time-consuming and costly. And yet, as they say, "the game is worth the candle", because they are not so actively subjected to human attacks and their indefatigable curiosity. Nature knows how to keep its secrets, from time to time yielding a piece of its treasures to man so that life on Earth can continue. Man, in turn, invents new technologies to receive earthly gifts.

Because the ground water lie at different depths, have their own water boundaries and outlines, in water well drilling technology have their own technological algorithms. Availability technical means, equipment, mechanical equipment, according to the developed project and agreed studies of rocks, soil composition, at the proposed drilling site, it assumes the start of work in compliance with the technology of drilling wells for water.

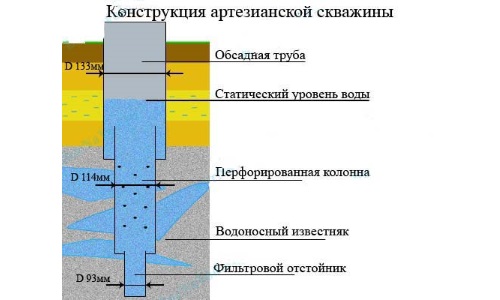

In the process of drilling, the well is cased with special pipes that prevent the earth from collapsing and dragging the well itself from soil pressure. Upon completion of the drilling of the initial section, the first casing string is lowered - the conductor, in order to block weak, unstable rocks and upper aquifers. Pumped into the annulus cement mortar. Drilling of the well continues inside the casing pipes, but with a bit of a smaller diameter up to the design mark, after which the next casing string is lowered into the well. When drilling a well, the lower part of the casing string is perforated and serves to improve the well flow rate. The flow rate of a well is a technical indicator of the amount of water produced. After the opening of the aquifer, the water rises through the well and is established at the so-called static level.

Then, according to the technology of drilling wells for water, a pump, a riser pipe are installed and, if necessary, a caisson is installed. The caisson is a metal container with a depth of 2 meters and a diameter of 1 meter and serves to prevent freezing of water in the riser pipe and connections. From the caisson, the pipe is led into the ground to a depth of approximately 1.80 meters (the average depth of soil freezing in Moscow and the Moscow region) and is brought to the house or to the object.

AquaAlliance specialists have tested the water well drilling technology in practice and confirmed it with reliability and workmanship. You can use the services of the company at any time of the year and at a convenient time for you. on our website, you can get clarifications and answers to questions in the section or on this issue.

Do-it-yourself water well is real way provide water plot within a private house, thereby building a reliable water supply for the future suburban area where there is no centralized water supply.

Arrangement of such a water source requires significant financial and labor costs. Drilling will require special tools and equipment, but with the right organization of work, everything can be done independently and reliably.

In order to equip your own well for water, you need find the right body of water, determine the depth of its occurrence and drill a channel (wellbore) in the ground, which is included in this productive layer. The main drilling methods are discussed below.

screw method

For such drilling, drill (auger) in the form of a rod with a cutter at the end and blades located along a helical line. Garden or fishing drills can be considered elementary augers.

The essence of the technology is in screwing the tool into the ground by rotating it and extracting the earth as it rises. The process can be carried out manually or mechanically way. You can drill a well manually using auger up to a depth of 8-10 m.

This technique is considered the most simple and affordable, but it can only be used if there is a sufficiently soft or loose soil. You can not use it in the presence of quicksand and rocky outcrops. In the presence of harder soil or deeper drilling, it is necessary to tool rotation mechanization. As the hole deepens, the auger is screwed to the drill pipe (string) section.

Hydrodrilling (hydrodynamic drilling)

Technology based on the combination of traditional drill and hydraulic action.

Technology based on the combination of traditional drill and hydraulic action.

At the same time, flushing fluid is constantly supplied to the drilling zone under pressure, which:

- helps destroy the earth;

- washes out the drilled soil, bringing it to the surface;

- cools the drilling tool;

- aligns the walls of the entire trunk as it moves.

It is water weighted with clay, and is fed into the well with a pump. Wells are usually made with the help of hydrodrilling. depth 30-50 m, but in principle, it is possible to drill a trunk even deeper than 200 m. To increase the drilling depth, a drill string is assembled from rods - pipes 1.3-2 m long, 45-75 mm in diameter.

Pneumatic drilling (pneumatic percussion drilling)

Refers to shock-rotational technologies. With this technique, the destruction of the rock occurs by impact with a pneumatic tool (pneumatic hammer), while the entire drill string is given a rotational motion.

For pneumatic drilling not afraid of hard rocks, and problems arise with clayey, viscous soils that quickly clog the tool. The depth of the drilled wells is small - up to 50 m (usually 15-25 m). Important advantage – high speed penetrations.

diamond tool

The most effective, but very expensive way to drill wells is considered to be core drilling using nozzles with diamond crowns . Such drilling rigs are capable of drilling at a very high speed in soil of any hardness. The main disadvantages are the small diameter of the trunk (up to 15-17 cm) and the cost of driving up to 500-700 rubles per 1 m.

Turbine technology

The method is based on the longitudinal advance of the drill bit, the rotational movement of which is provided by a turbodrill. All this is located on a submersible column, which is increased by rods as the wellbore deepens.

The main element - a turbodrill is an engine that plunges into the bottomhole zone, i.e. does not rotate the entire drill string. Drilling can be provided by low-speed (120-300 rpm) and high-speed (450-600 rpm) engines, while they are driven by the hydrodynamic force created by the fluid flow acting on the engine blades.

electric drill

This technology is not fundamentally different from turbine drilling. In this case, instead of a turbodrill with blades into the bottomhole zone immersed asynchronous type electric motor. The use of an electric drive makes it possible to abandon the drill string in the form of pipes and lower the electric drill on a cable-rope.

The main disadvantage is reduced performance cable in downhole conditions with frequent tripping operations.

Screw motors

These are modern, improved drives lowered into the bottomhole zone. They are voluminous rotary type hydraulic units. Their rotation is provided by the drilling fluid, and efficiency is increased by the use of low and high pressure chambers.

Important. The choice of drilling method depends on the depth of the productive, water reservoir, soil characteristics and the presence of difficult areas in the drilling zone, as well as the planned well flow rate and the availability of equipment and financial capabilities.

How are water wells drilled?

Any well designed to lift water from deep water to the surface. Its principle of operation is based on the arrangement of the wellbore in the form of a pipeline by installing a casing string (pipe) so that the bottom hole with a coarse filter is inside the water source, while the liquid is lifted by a submersible or surface type pump.

Thus, water enters through the holes in the bottom of the string and is forced up the wellbore to the surface.

Kinds

Taking into account design features and depth, the following types of water wells are distinguished:

- Abyssinian well(pipe well). It is constructed by driving a pipe into the ground, and therefore the depth is no more than 6-10 m. The water rises from the top layer (groundwater) and is heavily polluted. It can be used for technical purposes or for drinking, but only after boiling.

- Well on the sand. She drills deep 14-25 m, which allows you to use any method of drilling. Usually it is cased with a pipe with a diameter of 12-20 cm. The flow rate of such a well is small and it is intended for small farms. The work uses centrifugal pump surface mounted.

- Artesian well is drilled to the lower, productive water reservoir at a depth over 50 m. The water in it is absolutely clean and used for drinking. Lifting from it can only be carried out using a submersible pump.

Functional nodes

Any well, regardless of depth and variety, has the following functional areas and nodes:

- Downhole zone or water intake. This is the lower part of the well, which is located in the water reservoir. Here, through the perforation, water enters the casing string. Mandatory element - filter.

- Casing string (pipe) or suction line. Its task is to provide a sealed channel for water from the bottomhole zone to the pump inlet (pump intake), which must be supplied check valve to prevent backflow.

- Pump. It provides the rise of water, for which it creates a certain pressure.

- Hydraulic accumulator or storage tank . This node is responsible for protecting the equipment from water hammer, ensuring the water reserve and creating desired pressure in the plumbing.

- Pressure switch and control equipment.

- Well head. This is the upper, ground part of the well, which protects it from contamination from above, freezing and distribution of raised water.

Equipment

To equip a well for water, you need the following inventory and equipment:

- Pump. It is selected taking into account the depth and productivity of the well, the size of the casing, the length of the water main. With a shaft depth of up to 10-12 m, a surface, centrifugal pump of the required power is most often used. For deep wells, a submersible type pump is used. It requires a carrier, safety cable and a submersible electrical cable.

- Pumping station with the system automatic control process. It must have monitoring devices and overload protection devices.

- Hydropneumatic tank. It is designed to maintain a stable pressure in the system and optimize pump performance. A constant water level in it is maintained by a level switch. The dimensions of the reservoir depend on the capacity of the equipment and the flow rate of the well. The volume can vary widely from 20-30 to 1000 liters. Containers with a volume of about 100-150 liters are considered optimal.

- Caisson. The borehole head can be equipped different ways, but the most popular is the caisson, which is a metal box (tank) that seals the wellhead. It is mounted with a small depth (up to 1-1.2 m) and has dimensions sufficient to accommodate connecting equipment and a serving person.

- Communications. Cable, wire to ensure reliable power supply and water pipes from the caisson to the points of water consumption.

note

The upper part of the well and the water supply are in the zone of soil freezing, and therefore they must be reliably insulated.

Mounting sequence

The submersible pump is mounted in the following sequence:

The submersible pump is mounted in the following sequence:

- installation of a check valve (if it is not included in the pump kit);

- fastening on a cable and connecting a cable;

- immersion of the pump to the desired depth;

- installation and connection of a hydraulic accumulator (hydropneumatic tank);

- connection and adjustment of the control and monitoring system;

- installation and connection of fine filters;

- connection to consumption points (heating equipment, mixers, etc.).

Downhole device scheme

A standard deep well device with a submersible pump has such basic design:

- perforated water intake of the casing pipe with a sump;

- coarse water filter;

- submersible pump with check valve and water intake;

- conduit or pipe (hose) for lifting water connected to a pump;

- waterproof cable for pump power supply;

- borehole or expanded upper part of the wellbore;

- cap, caisson;

- shut-off equipment (ball type valve);

- control devices, pressure gauge (up to 8-10 bar);

- pumping mechanism with a ball valve.

The scheme of the well is quite standard:

- Water under the pressure of the formation seeps into the sump and accumulates in it.

- When the pump is turned on, water rises along the casing string, enters the pumping water intake and goes up the conduit.

- In the caisson, water is sent to a hydraulic accumulator, where a certain supply of it is created, after which it enters the water supply system.

How is a well set up?

When a productive reservoir, a water carrier, is reached in the process of drilling, the stage of arranging a well for water begins. First, the lower filter column is lowered into the shaft, which is a pipe with a perforated tip, a settling chamber and a filter of several meshes, which prevent the penetration of large fractions of impurities.

Next, the entire casing string is mounted, and the gap between it and the ground is filled with sand and fine gravel. Simultaneously with backfilling of the mixture, the well is pumped by supplying water with sealing of the wellhead.

After cleaning the bottomhole, a submersible pump is lowered on a cable with a connected conduit with a diameter of 25-50 mm, depending on the flow rate of the well. The casing string and wellhead protection are fixed on the head. A shut-off valve is installed in the outlet system. In the caisson, a water conduit and a water pipeline are connected.

Well is enough difficult hydraulic structure , but with its proper arrangement, a reliable own water supply appears. All operations, starting with drilling the well, can be done by hand, but for this you must follow all the recommendations of specialists and use standard equipment.

Useful videos

The cheapest and easiest to manufacture hydraulic drill and its test when drilling an aquifer:

How to drill with your own hands from sheet metal, look:

The same well, purpose and device:

Do-it-yourself methods and options for cleaning a household well from silting:

Before drilling, it is important to make sure that the water reservoir is sufficiently productive, for which professional geological surveys are required.

The most affordable and simplest source of water supply for a private house, cottage or bath is a water well.

To secure land clean water, preliminary preparation will be required: analysis of the main soil parameters, calculation of the depth of aquifers, selection suitable option arrangement of a water intake point. Based on the data obtained, it is determined effective method bottomhole and water wells are being drilled.

At the same time, equipping a well is independently available to any owner of the site, the main thing is to correctly apply the drilling technology.

Drilling water wells is a time-consuming and responsible process that requires the right approach to application modern methods drilling. The main set of works can be performed independently with a minimum set of equipment, without involving third-party contractors.

This will save on professional drilling and rental of specialized equipment. An important cost item for well construction will be the basic calculations and collection of analytical data on the state of the soil and the location of the aquifer.

The most popular type of hydraulic structure that you can equip yourself is a water well with a casing depth of up to 35 meters. Structurally, it is represented by a pipe that is installed in the shaft and equipped with a filter for bottom water purification.

For self-development of a water intake point, experts recommend choosing the method of auger drilling using an electric or gasoline drilling rig. This greatly simplifies the process itself and reduces the time spent on well construction.

The right choice of location for well development

How do you drill a well for water? It all starts with a choice suitable place for arranging a water intake point. To determine the water source on land plot it is recommended to take into account the following signs:

- An accumulation of vegetation that prefers high soil moisture in certain areas.

- Cluster small insects, as well as the rest of domestic animals - cats and dogs - in places where the aquifer lies.

- The occurrence of humid fog and dew in the evening and morning. In winter, the appearance of thawed patches.

The above indications of the discovery of an aquifer are considered indirect, therefore, in order to obtain more accurate results, it is recommended to conduct basic geological surveys.

Experts will help determine the depth of aquifers and provide analytical data on the state of the soil on the land.

Types of wells for water

There are several types of wells for organizing a water supply system, which depend on the level of passage of aquifers.

- Wells on the sand. The most common version of hydraulic structures, which is characterized by low cost and availability of work. Structurally, a similar well is represented by a casing string equipped with a bottom filter. The water debit of the source can be from 6 to 950 cubic meters per day. A well in sandstone is equipped to a depth of 5 to 11 meters (with automatic drilling - up to 25 meters). The service life of a hydraulic structure is from 8 to 16 years.

- . The most time-consuming and expensive option for arranging water supply facilities, which provides for the mandatory availability of project documentation and. The design of the well is represented by two columns - casing and water. The casing pipe is mounted in ordinary soil, the water pipe is installed in limestone deposits, while the water supply is carried out under high pressure. The water debit of the structure is from 8 to 42 cubic meters per hour, the diameter of the pipe is taken into account. The maximum casing depth is 300 meters. The service life of the structure is up to 45 years.

- . Settled in moving soils with high content sand and gravel, have a low water debit - up to 3 cubic meters per hour. The maximum laying depth does not exceed 12 meters. The well is not subject to repair and restoration, it is prone to rapid drying and silting.

Since it is planned to drill a well with one's own hands, the most affordable technologies for self-development will be considered below.

Basic technologies for the construction of aquifers

You can independently drill a well under water using the following available technologies:

Auger drilling technology

The easiest and most affordable way to equip a borehole channel with a drilling rig. It is used in mobile loose soils - clay, loamy and wet sandy loams.

A drill equipped with rotating blades (auger) is inserted into soft soil layers. When passing a meter section, the installation raises a part of the withdrawn soil mixture (sludge) to the surface. As it goes deeper into the ground, the drill rod lengthens with additional links. The rotation of the auger is provided manually or by means of an electric drive.

The technology is the most productive and efficient. It allows you to perform the whole range of work manually without equipment or with the help of self-made small-sized drilling rigs - a drilling tripod and a lifting mechanism. Such structures provide easy passage of the soil and lifting the mass to the surface.

Core drilling technology

The principle of operation of drilling equipment is similar to the previous one, the difference lies in the design of the cutting part of the drill. The drill is a cylindrical hollow device, equipped with soldering for the passage of rocks of various densities. The sludge collects inside the cylinder and is removed from it every time it rises to the surface.

This technology is used in areas with different types of soil and allows you to equip a well of the desired diameter.

Core drilling is rarely used for self-development of a borehole channel, since it involves the involvement of expensive specialized equipment that provides a uniform load on the drilling rig.

Rotary hydraulic drilling technology

During the drilling process, a continuous supply of flushing fluid under pressure is carried out. It is designed to flush out cuttings and clean the drilling rig.

There are two ways to supply liquid:

- Direct flushing - when water is supplied to the column and is discharged with sludge into the space between the pipe and the column.

- Backwashing – fluid enters the well string from the annulus, after which it is brought to the surface.

To drill a well, MGBU with hydraulics are used, providing a direct method for flushing the column.

This technology is effective for arranging wells, the depth of which exceeds 10 meters.

Rope percussion technology

This well drilling technology is complex and time-consuming to implement, but it remains the most practical and reliable.

Penetration is carried out due to successive shocks of the drilling cylindrical installation when changing the position up and down. The soil mixture enters the cylindrical cavity and rises to the surface.

advantage similar way drilling is the possibility of passing various types soils, it does not require the lengthening of the drill at a depth. In addition, such equipment can be made independently from improvised means.

A mechanical or electrical mechanism may be used to lift the drilling cylinder.

Varieties of drilling tools

The main working tool for drilling a well and lifting soil is a drill. For various ways drilling are applied:

- An auger, or coil, is used for a rotary drilling rig when passing medium-density soils - loam, sandy loam, clay and earth. Equipped metal nozzle with sharpened edges for drilling in the ground.

- A glass, or Schitz projectile, is used for viscous and dense soils in cable-percussion drilling rigs.

- The spoon is used for loose and moving soils - sandy, gravel. The drilling method is rotary and percussion-rotary.

- is used to clean the borehole channel from semi-liquid and loose soil mixtures remaining after the passage of the bit. Intended for cable-drilling installation.

- The chisel is used for passing hard and stony rocks. It is a special plate with rounded edges with a caliber equal to the inner diameter of the casing string minus 5 mm. Designed for cable-percussion drilling method.

The cutting elements of the drills are made of hardened steel sheets with a thickness of 3–5 mm.

Well Casing Features

Any well for water provides mandatory installation casing. For this, metal, plastic or asbestos-cement pipes are used.

Installation of the casing pipe is carried out at the stage of drilling or well completion.

After drilling is completed, a casing pipe is installed on the well bottom, at the end of which there is a bottom filter equipped with a fine mesh to remove foreign impurities from the water. To prevent possible subsidence of the pipe, it is securely fixed with clamps.

Next, the next pipe is installed in a similar way and connected to the previous element. Excess soil is removed with a bailer. A cap is installed in the upper part of the structure above the ground to protect the well from possible contamination.

After the installation of the casing is completed, its arrangement, as well as connection to the water supply system, are carried out.

Step-by-step instructions for developing a water well

Now let's figure out how to make a well in sandy soil using.

The development of a new hydraulic structure begins with the preparation of a working draft. In order to prevent serious design errors, it is better to entrust this work to specialists.

Self-drilling technology involves the following steps:

- Drawing a marking on the allocated zone under drilling of a well.

- Digging according to the finished marking of a pit measuring 150 × 150 cm for immersing a drilling tool - a bailer, an auger or a drill. The pit is a special recess in the ground, which is intended for the development of a borehole channel.

- Installation of a working tool.

- Implementation of drilling taking into account the chosen method.

- After completion of the penetration, installation of a filter unit - a structure that consists of a bottom filter, a sump and a supply pipe.

- Backfilling of the annular space with a sand-gravel mixture. This will secure the casing in the borehole.

- Sealing the upper part of the pipe and filling the cavity with water using a pump to clean the filter.

- Pumping fluid from the well with a bailer or screw pump.

- After complete cleaning of the hydraulic structure and the aquifer, the pumping equipment is lowered into the casing using a metal cable.

- Connecting the hose and water pipe to the pumping equipment.

- Installation of a valve on the pipe to regulate the water pressure.

- Installation of waterproofing of the above-ground part of the casing to protect against high humidity and temperature fluctuations.

- Mounting on the wellhead of the caisson with fixation on the head.

- Pad water pipes from the house in earthen trenches.

- Performing external sprinkling of the caisson with earth and arranging a concrete blind area.

This is a general scheme of how you can drill an aquifer yourself to organize an autonomous water supply.

At self-conduct the main thing is not to rush and follow all the main stages technological process well development. At the same time, one should not forget that the use of high-quality and durable components (pumping equipment, filters and pipes) is a guarantee of reliable and safe operation of the well.