Insulation in construction is assigned a separate column. For each object, its own material is selected, which will be used for these purposes. One of the universal is penoplex. It is used everywhere. Why has he gained such popularity? What features make it stand out from its competitors? This is what the article is about.

History of appearance

Penoplex is a material that is obtained by extrusion. His appearance was impossible without the appropriate equipment. For the first time such a machine appeared in the USA more than fifty years ago. As a result of several experiments, it was possible to come to the exact form that penoplex has today. In fact, the word "penoplex" has become a household name from the name of the manufacturer "Penoplex". It is he who has been the leader in the production of this material in Russia since 1998. The production process itself is quite simple, but requires sophisticated equipment.

The foam insulation is based on polystyrene granules. They melt under the influence of temperature to a homogeneous liquid mass. The process takes place at 140° Celsius. After that, substances are added to the resulting mass, which, when heated, begin to emit gases. The latter create foam inside the polystyrene mass. The bubbles do not burst or float, but remain in the melt. During this stage, additional substances are introduced, which, for example, increase resistance to open fire, preventing the finished product from igniting, but only melting. Other additives are antioxidants. Their task is to extend the service life of the finished product under the influence of various factors, in particular, air that contains oxygen.

Mandatory are antistatic agents in the foam insulation. The fact is that during installation on the sheets it can accumulate a large number of static energy that can harm electrical appliances. After the solution is completely ready, it is squeezed out through a special molding hole in the extruder. The formed elements get on the conveyor and move further. The final product consists of only 2% polystyrene and additives, the rest is occupied by gases that were formed from catalysts. In this case, the size of the bubbles is correct due to the formation under pressure. Below is a video about the production of foam.

Specifications

Knowledge of the technical characteristics of the penoplex will make it possible to apply it in the right way when insulating various parts of the building. It is important to know how penoplex insulation is able to withstand moisture, provide sound insulation or interact with other building materials.

Hygroscopicity

Hygroscopicity is a measure of the ability of a substance to absorb moisture. If the insulation has a high value, then it cannot be used in rooms or conditions. high humidity. After absorbing water, it will lose its properties and a fungus may appear in it. Penoplex insulation has a minimum indicator of hygroscopicity. An experiment was conducted during which a piece of polystyrene foam was completely lowered into the water. He stayed in the vessel for a month. After weighing the control sample, it was found that it still absorbs moisture. It amounted to 0.6% of the total mass of a piece of foam. At the same time, moisture did not get inside the sheet. It's just not possible. All granules are sealed and do not come into contact with each other, so water cannot accumulate with them. And the percentage of weight that was gained is explained by the ingress of water into the damaged bubbles that remained after cutting the foam.

Thermal conductivity

Thermal conductivity is one of the main indicators that pay attention to insulating material. For example, in an oak that has been sawn across the grain, it is 0.1 W×m×K. This is a pretty good indicator, which allows you to build buildings from logs without any special difficulties without additional insulation. For foam plastic, this figure is 0.03 W × m × K, which is three times lower than for oak. Paired with minimal water absorption, penoplex insulation becomes an ideal material for insulating buildings or foundations that are constantly in a humid environment.

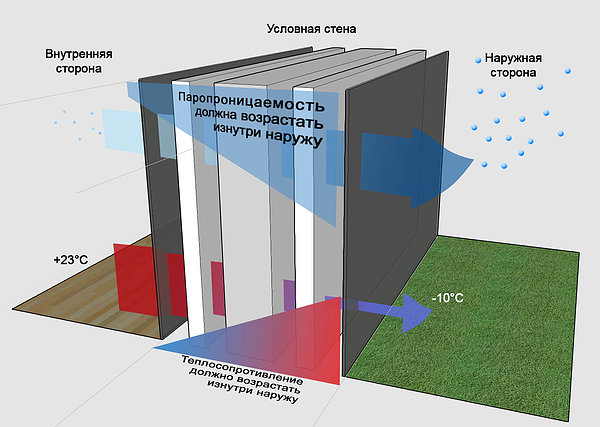

Vapor permeability

Vapor permeability is a certain feature of materials to carry out gas exchange. It is essential for a healthy indoor environment. The ability of the material to vapor permeability is explained by its porous structure. The vapor permeability process itself depends on partial pressure, which may not depend on atmospheric pressure. Penoplex has a very low vapor permeability index. This means that they cannot carry out the insulation of the premises from the inside. This will certainly lead to the fact that a fungus will begin to develop between the wall and the foam, which will cause trouble for both the building material and the health of the owners. Mounting penoplex is only outside and it is mandatory to lay a vapor barrier. But this is a positive thing for refrigeration or heating equipment. Penoplex insulation is able to retain heat or cold for a fairly long period of time.

Environmental friendliness

During the production of penoplex, no substances are used that, over time, are capable of producing emissions that would be harmful to humans. It is true that freons are used in the manufacturing process of penoplex, but this is not the category of elements that destroy the ozone layer or become toxic when heated. Perhaps for someone the argument will be that foam insulation is used in a bath at a research station in Antarctica.

combustibility

Almost all materials that are used for insulation burn well. This applies only to polymers and does not apply to stone wool. Different types of penoplex are subject to combustion to varying degrees. Those that have anti-flammable additives may simply melt. But there is a penoplex insulation free of fire retardants. Such a foam insulation burns well. In this case, not only carbon dioxide is released, but also other substances that can harm human health. But this harm does not exceed in its indicators that which can be caused by such burning materials as wood, plastic, MDF and others. During a thermal reaction, hydrocyanic acid is not released, so this statement can be considered a myth.

Chemical resistance

Before covering the foam insulation with any composition, you need to know exactly how they will interact. For the most part, penoplex insulation perfectly tolerates proximity to building materials and more. These include various types of alcohols and paints that are diluted with alcohol. If near the penoplex you have to work with various types acid, don't worry. He perfectly tolerates their impact without any damage. Alkalis, ammonia, natural gas, cement mortars and vegetable fats.

At risk are paints on oil based that can destroy the foam insulation. Benzene, xylene and derivatives will also not leave hope for the insulation. You should also beware of using ethers next to such a heater. The heater does not tolerate neighborhood with all types of liquid fuels, so if there is a desire to wash off paint or other substance, it is better to do this as far as possible from the polystyrene foam.

Life time

The service life of a material is most often determined by its resistance to temperature extremes. For this, the heater is satisfied with extreme conditions. In them, he has to repeatedly freeze and again return to a state above zero. Some Construction Materials after 30 such drops, they simply crumble into powder. Extruded polystyrene foam is able to endure several hundred such procedures. The average service life of the insulation would be set at 50 years. But this is not the limit. During the tests, the insulation material was also exposed to other factors that are an integral part of its daily operation.

Mechanical influences

Due to the structure of the material, penoplex insulation perfectly tolerates mechanical loads. This is due to the stability of the walls of the bubbles that are in the thickness. With significant physical effort, the penoplex can bend, but subsequently restore its shape. This makes it possible to use insulation even under roads where the throughput exceeds a thousand cars per day. Depending on the density, the resistance of the insulation to compression may vary.

Varieties of penoplex

The foam insulation manufacturer has several solutions in its arsenal that are suitable for insulating specific sections of a building or other surfaces. One of them is foam insulation for the foundation. At modern construction Basement insulation is a must. For this, this type of polystyrene foam is suitable. It is also called foam 35. In this type of insulation, there are no additives that guarantee attenuation, so it is a fire hazardous material, but this is not so critical, because a fire almost never starts from the foundation. The thermal conductivity of this subtype of insulation is 0.03 W × m × K.

The most common and versatile is foam insulation, which is used for wall decoration. They can also insulate the floor and foundation. In the manufacturer's catalog, it is listed as "Wall". He came to replace the insulation with an index of 31, which has flame retardant additives. It is they who prevent the combustion of the insulation, reducing it to smoldering. The thermal conductivity is also 0.03 W × m × K, but the density is slightly lower than that of the foundation and the maximum is 32 kg / m 3. A separate type of insulation is designed for roof insulation. It has the same thermal conductivity as the two previous versions of foam plastic, but the density is slightly higher than that of the wall and is 33 kg / m 3. Such a foam insulation will provide additional sound insulation to metal flooring.

Insulation of road surfaces is also not a problem for foam. For this, there is a heater with an index of 45. Its density reaches 47 kg / m 3. Such insulation has the highest degree of resistance to compressive force. Even the runways are tough for such foam. Another universal type of insulation that comes with a sheet thickness of 20 mm or more is "Comfort". Insulation can be used for walls, balconies, saunas and other purposes. The standard dimensions of all types of penoplex are 120 by 60 cm.

conclusions

As you can see, the Penoplex manufacturer has prepared an excellent product line, which has become the undisputed leader among heaters. Many began to copy the technical process of production and a large number of purely domestic analogues appeared.

Of the modern heat insulators, penoplex is considered the most effective. This insulation material is made from extruded polystyrene, which automatically makes it cheap, but superior in technical characteristics, such as moisture absorption and sound insulation, other heat insulators.

Penoplex production and varieties of material

The production of foam plastic is organized according to the following technology: small polystyrene granules in a sealed chamber are exposed to high temperatures (130 0 C-140 0 C), as a result of which they melt, and after adding porophores they foam. Porophores are synthetic additives that, during heating, release nitrogen and carbon dioxide, which, after cooling the foam, turn into frozen air bubbles, evenly distributed throughout the material.

Components of porophores for the production of extruded polystyrene foam (foam plex):

The frozen foam may contain some synthetic fillers, the presence of which determines the direction of the use of insulation - for walls, foundations, etc. The most common additives are flame retardants to increase fire safety (reduce the degree of flammability), antioxidants to protect the material from oxidation on outdoors, antistatic substances to relieve static and dynamic stress during the operation of the heater, light stabilizers (protection against negative impact UV radiation), modifying additives, etc.

Polystyrene foam under pressure is extruded from the extruder chamber onto a conveyor for final formation into slabs or blocks. The percentage of gases in the insulation reaches 98% of the total volume of the finished foam, so the products are light in weight with impressive dimensions. Dimensions for each functional line of insulation are shown in the tables below.

The small pore size (0.1-0.3 mm) and their complete isolation from each other guarantees high thermal insulation performance of any grades of foam. For different construction projects, it is necessary to select the appropriate series and brands of insulation, since structures can be operated in different conditions:

- Brand "K" is designed for insulation of pitched or flat roofs and roofs. Specific gravity(density) series "K" - 28-33 kg / m 3;

- Series "C" - insulation for internal and external walls with a substance density of 25-35 kg / m 3;

- Brand "F", basement and basement. Material with high moisture resistance, biological stability and specific gravity ≥37 kg/m 3 ;

- Penoplex brand "Comfort" - a universal series of insulation with a density of 25-35 kg / m 3. Direction of application - insulation of apartments, houses, basements, balconies and loggias;

- Brand "45" has the highest rates of frost resistance and strength, specific gravity 35-47 kg / m 3. Designed for thermal insulation of the roadway, runway, and other heavily loaded objects and structures.

A separate category is produced sandwich panels, which are an improved heat insulator for insulating attics and mansards, facades and foundations of buildings. Sandwich panel has 2-3 layers and cement chipboard as the bottom layer.

Operational and technical properties of penoplex, advantages and disadvantages

- Thermal conductivity - 0.03 Wm 0 С, the indicator does not decrease even with strong moisture;

- Water resistance - 0.4-0.6% when immersed in water for 24 hours and for a month;

- The vapor permeability of the material can be compared with the same indicators of roofing material with a layer thickness of 20 mm;

- Chemical passivity: penoplex does not react to contact with mortars and most aggressive substances. Substances with which Penoplex contact is contraindicated: kerosene, acetone, formaldehyde, benzene, xylene, toluene, formalin, methyl ethyl ketone, ether, diesel fuel, gasoline, tar, paints and epoxy resins;

- High mechanical resistance to stretching, compression, tensile forces and multi-vector pressure. The compressive strength index of foam plastic is 0.2-0.5 MPa;

- Biological neutrality - penoplex does not get sick with mold, does not decompose and does not rot;

- A wide range of operating temperatures - from -50 to +75 0 C. The temperature range for each brand is indicated on the package;

- Combustibility groups for different brands are different, from G1 to G4, depending on the operating conditions;

- Environmentally friendly material without the use of phenols and freons in the production;

- Guaranteed service life ≥55 years without noticeable loss in properties.

Advantages of penoplex:

- Thermal conductivity properties make it possible to use penoplex even in the Far North - multiple freeze / thaw cycles of the material do not affect its characteristics;

- Light weight makes it easier to transport, store, store and insulate the object, makes it possible to lighten the foundation and not to strengthen the ceilings;

- Simple installation without the help of specialists and special tools - penoplex is easily cut with a conventional hacksaw or cutter;

- Safety and environmental friendliness - you can work with the material without personal protective equipment;

- Low cost of all brands of insulation. Even with a high consumption of a heat insulator, the cost of its purchase and installation pays off in 2-3 seasons.

Disadvantages of penoplex:

- Low fire safety - a material of any combustibility group, even with flame retardant additives, can ignite with the release of acrid toxic smoke;

- Low coefficient of vapor permeability, and under certain weather conditions - negative. Therefore, penoplex is not recommended for internal insulation of the walls of the house. To save optimal conditions operation of the insulation, it is necessary to provide forced ventilation in the house and ventilation of channels in the walls insulated with foam plastic;

- The destruction of the material when exposed to ultraviolet radiation - sunlight. It is necessary to protect the insulation layer with plaster or other methods;

- Because of smooth surface the adhesion of foam plastic with solutions is rather low, therefore, it is necessary to fix the insulation only on dowels or special expensive glue, but not on mortars.

Heat-insulating material "Wall" - properties and characteristics

The Wall brand is a renamed Penoplex 31 insulation with flame retardant additives, which has been improved for use in the insulation of “wet” facades, building foundations, plinths and basements, partitions and walls of houses from the outside and inside, roofs and attics. Characteristics of foam brand "Wall" - in the table below:

Insulation brand "Foundation" - parameters and properties

The Foundation brand is a renamed Penoplex 35 insulation without fire retardant additives, which can now be used to create thermal insulation for the bases and plinths of buildings, blind areas and basements. The strength, water resistance and thermal conductivity of the series are its main advantages. The characteristics of the "Foundation" are given in the table below:

Penoplex "Roof" - properties and characteristics

Foam insulation of the "Roof" series is a renamed material "Penoplex 35", which is recommended for use in the insulation of pitched and flat roofs any design. The use of the "Roof" series makes the further operation of the roof as simple as possible, since reliability and long term operation of the insulation minimize the possibility of repairing the roof surface. The popularity of this innovative insulation material caused by the fact that on such a surface it is possible to arrange greenhouses and summer gardens- such trends are now in vogue. Penoplex can withstand such high loads that it can handle a load of soil up to several tons. Characteristics of the brand of insulation penoplex "Roof" - in the table below:

"Comfort" - a universal brand of heat insulator

"Comfort" - a universal brand of heat insulator Heat insulator brand "Comfort" - properties and characteristics

Penoplex "Comfort" is a modified and improved "Penoplex 31C" with universal characteristics. The material is actively used for insulation suburban buildings, country houses and cottages. High installation speed and minimal labor costs popularize the insulation among private homeowners - it is used to insulate the subfloor, foundation and basement of the house, basement and roof, walls and partitions inside and outside the building. Penoplex "Comfort" has high rates of moisture resistance and thermal conductivity. In the line of the penoplex series, the Comfort brand is recognized as universal.

Penoplex protects the soil from heaving during freezing - when the soil is insulated with this material, the freezing point of the soil will rise. This series is optimal for thermal insulation of road and railway tracks, runways and technical areas of airfields. Plates "Comfort" retain their unique characteristics throughout the entire period of operation. Characteristics of the brand of insulation penoplex "Comfort" - in the table below:

It is a delusion to think that foam and polystyrene are brother materials. Some properties of foam can be equated to the parameters of the foam, but not combustibility and water absorption.

Manufacturers have long mastered the manufacture of both non-combustible foam plastic and well-burning foam plastic. But the truth is that foam plastic cannot ignite spontaneously, and in the open fire zone it will only melt, releasing carbon monoxide (CO) and carbon dioxide (CO 2) gases. If the fire is eliminated, then the penoplex will not even smolder.

For a comfortable stay in the cold season, when building a house, you need to take care of its high-quality thermal insulation. There are a huge number of insulation materials on the market, differing in characteristics and cost. The most effective of them is penoplex. Specifications, types and cost this material different manufacturers are described in this article.

Read in the article

What is penoplex: types

Penoplex (or erudite polystyrene foam) was invented in the USA over 50 years ago. It immediately won the trust among buyers for its low cost and cost. During production, the granules are pressed under pressure and high temperature, while a special catalytic agent is used for foaming. Next, the mass is squeezed into molds, and after a while the cells are filled with air. Thanks to this process, the porosity is uniform, and the resulting substance is strong and light.

Currently, there are three types of penoplex:

- Penoplex 31 Standard. It has poor resistance to compression, so it is mainly used for . However, in some cases (when the load is not too high), they are insulated, and much more.

- Penoplex 35. The most popular type of this material is currently due to the presence of a flame retardant in the composition - a substance that improves. Therefore, in the construction of buildings in most cases (for floors, walls, roofs, and so on), it is he who is used. For example, foam 50 mm class 35 - perfect solution for insulation, the use of 30 mm foam is more rational for walls and.

- Penoplex 45. The most durable of the presented types. Due to the high density, such insulation is able to withstand high loads, therefore it is used even in the construction of roads to prevent swelling during freezing. Indeed, in the warm season, some types of soil under the road actively absorb water, but in winter, this may cause the road surface to crack. And if you use a heater, freezing will be minimized or not happen at all.

Thus, during construction, it is necessary to choose the right type of material to prevent the building from settling and save money (if the load is small, you can choose Penoplex 31 Standard).

Penoplex 35 is divided into four types according to its purpose:

- Penoplex Comfort.

- Penoplex Foundation.

- Peroplex Roof.

- Penoplex Wall.

Each contains a flame retardant, but some specifications foam 35 different types diverge, so let's look at them in more detail.

Penoplex Comfort: technical specifications

Penoplex Comfort is the most versatile insulation of all the types presented. It is suitable for the foundation, and for walls, and for. It was during the production of this type that the L-shaped joints of the plates were first tested, which reliably seal the joints and therefore are now used in most cases.

This material has the following specifications:

- Thermal conductivity of this material is about 0.03 W/m*℃. The best thermal conductivity among all insulating materials is achieved due to the fine-mesh structure (0.1-0.2 mm).

- Vapor permeability– 0.013 Mg/(m*h*Pa). This indicator is practically zero, so the water absorption of this erudite polystyrene foam is almost completely excluded.

- Flammability class- G4 (highly combustible). Despite the high degree of fire hazard, spontaneous combustion of this material is impossible, and its smoldering can be extinguished quickly.

- High strength. The material is able to withstand a load of 20 tons per 1 m 2.

- Penoplex Density. Comfort is in the range of 25-35 kg/m 3 . It depends on the thickness and purpose of the product.

- Record durability– 60-90 years even in harsh conditions (high humidity and low temperatures).

- Wide range of sizes. The size of a standard plate is 1200 × 600, but the thickness can vary from 20 to 100 mm. Each type is suitable for specific purposes, for example, the technical characteristics of Penoplex Comfort 50 mm allow it to be used for foundation insulation.

- Wide operating temperature range-50÷+75℃.

Important! Due to the high flammability of this material, it is not recommended to use it in industrial premises where open flames are possible.

Penoplex Foundation: specifications, features

The main scope of Penoplex Foundation 50 mm - insulation and any buildings and structures. Due to its high resistance to moisture, to heavy loads, as well as the ability to not change its original characteristics for many years, this material reliably protects the building from ground water and does not sag during long-term use.

Installation of the foundation is a long and laborious process, the use of Penoplex Foundation allows it to be simplified and accelerated, since such plates are mounted in a matter of minutes. In addition, the following technical characteristics of penoplexageo are distinguished:

- Material density 29-33 kg/m³. For this type of penoplex, this indicator is quite important, since the compressive strength depends on it;

- Compressive strength at 10% linear load, not less than 0.27 (2.7; 27) MPa (kgf/cm2; t/m2);

- Static bending strength not less than 0.4 MPa;

- Water absorption in 24 hours no more than 0.4% of the total volume;

- Water absorption in 28 days- 0.5% of the volume;

- fire resistance- class G4;

- Coefficient of thermal conductivity under normal conditions (25℃) - 0.030 W/(m*K);

- under operating conditions "A" 0.031 W / (m * K);

- Estimated thermal conductivity under operating conditions "B" 0.032 W / (m * ° K);

- Operating temperature range- 50÷+75°С.

Features Penoplex Roofing: technical specifications, operating conditions

- part of the building that is constantly exposed to impacts environment. Therefore, all its layers, including insulation, must meet the high requirements of strength and moisture resistance. Penoplex Roof - the best choice in terms of price-quality ratio.

All technical characteristics of this material are identical to Penoplex Foundation. The only exception is the Compressive Strength Factor (0.25 MPa), which is somewhat lower, because the roof does not experience such loads as the foundation. Therefore, by reducing this indicator, the cost of the material is somewhat reduced.

The main feature of Penoplex Roofing is the ability not only to retain heat indoors during the cold season, but also to protect it from exposure to sunlight in summer. Thus, a comfortable microclimate in the house will be maintained all year round.

Another advantageous difference from other insulating materials is the high rate, so that birds and branches hanging over the roof will not interfere with your comfortable living.

Penoplex Wall: purpose and characteristics

The best solution for - penoplex. The price of Penoplex Wall is lower than that of other types of this material, since its strength is somewhat less - 0.2 ÷ 0.25 MPa. However, this does not prevent it from being used under the following conditions:

- (including sandwich panels and enclosing structures of block houses).

- Insulation of the outer plinth of the house.

- thermal insulation internal partitions(for example, in the basement).

The main feature of this material is the possibility of its use in multilayer decorative trim. Due to its special properties, it is able to withstand loads from, lining and so on. In addition, due to the minimum water absorption, any wet solutions can be used.

Extruded polystyrene foam: specifications and price

Extruded polystyrene foam has won its popularity among builders around the world due to the special quality achieved through a unique production process.

Technical characteristics of the technoplex:

- Steam and waterproof.

- Environmental friendliness.

- Durability.

- High compressive strength due to a smooth cellular structure (for example, the technical characteristics of 50 mm foam plastic allow it to withstand maximum loads under almost any atmospheric conditions).

- Light weight.

- Low thermal conductivity.

- Ease of installation.

- biological stability.

- Almost complete absence of chemical reactions.

- Flammability.

The ability to repel moisture is an important indicator for all thermal insulation materials. Extruded polystyrene foam has the highest water resistance index. An experimental study was even carried out with this material: it was placed in water for 10 days. When the period came to an end, the water was only in the outer cells, which were damaged during transportation or cutting, not a drop got inside the material. In addition, the vapor barrier index is also high, it can be compared with the level of roofing material.

Interesting! Many argue that the building envelope must breathe, that is, all layers of the walls, ceiling and floor must let air through (and hence steam). However, heat is also lost with air, which is unacceptable for thermal insulation material. For ventilation, you should equip a high-quality ventilation system, and not create air movement inside the walls.

In the production of this material, freons act as a catalyst, which are absolutely safe for the environment and are completely displaced by air even during manufacture. That's why environmental Safety this material at the highest level.

Penoplex manufacturers claim that the service life of this product is at least 50 years. Moreover, experiments have revealed that extruded polystyrene foam is able to withstand temperature changes and numerous freezes without losing its original characteristics, so it can be used in any region of the country.

Thermal conductivity - main characteristic insulation. Penoplex has the lowest rate in comparison with other materials for insulation. Moreover, depending on the percentage of moisture content in the material, it varies slightly. Therefore, extruded polystyrene foam is perfect for any surfaces, including the roof, the penetration of moisture under which is quite large.

Extruded polystyrene foam is not only resistant to moisture, it does not react with most chemical substances(e.g. salts, alkalis, alcohols). However, there are also exceptions, some compounds are able to destroy the structure of this material and even completely dissolve it (for example, hydrocarbons, ethers, oil paints). In addition, due to the absence of a biological component, this material does not attract microorganisms, so rotting is completely excluded. However, they are able to spoil it by making tunnels in it.

Plates of this material are lightweight, so they are easily mounted without the use of any special tools. Plus, they're easy to cut. with an ordinary knife, so anyone can handle the installation.

The only obvious drawback of this material is flammability. Depending on the type and presence of flame retardants in the composition, it belongs to different classes fire hazard. But in general, we can say that this material does not have resistance to open sources of fire. However, foam plastic does not burn, but only melts, and if the fire is extinguished immediately, there will not even be residual smoldering.

Foam sheet dimensions

The dimensions of the foam boards are standard - 1200 × 600 mm. They differ only in thickness, on which, for ease of use, depends how many pieces are in the package. Penoplex is from 20 to 100 mm thick. So plates of the "Comfort" type are completed from 4 (with a thickness of 20 mm) to 18 pieces per package (with 100 mm).

The most common sizes for Penoplex Foundation are 50 and 80 mm. They are completed in 8 and 5 pieces, respectively. It depends on how many m 2 are in the package (50 mm Penoplex Foundation, has a total area of 5.76 m 2).

Overview of foam prices 50 mm, 30 mm, 100 mm

How much does penoplex cost? Depending on the purpose and characteristics, the sizes and prices per piece of penoplex vary significantly. First of all, the cost is affected by: strength, resistance to moisture and thickness. Therefore, based on these indicators, below is a comparative table.

| Name | Characteristics | Peculiarities | |

Plates Penoplex Comfort 30 Plates Penoplex Comfort 30 | 0.12 MPa | The strength and thickness of this material is quite low, so it is recommended to use it only in places where increased load is excluded. The main advantage is the low price of foam plastic per sheet and resistance to moisture. | |

| 0.5% by volume | |||

| Width | 600 mm | ||

| Length | 1200 mm | ||

| Thickness | 30 mm | ||

| Price | 115 r. per sheet | ||

Plates Penoplex Foundation 50 | Minimum material strength | 0.27 MPa | Due to the high strength of both compression and bending, such plates are perfect for insulating the foundation in any region of our country. |

| Water absorption in 24 hours, no more | 0.4% by volume | ||

| Width | 600 mm | ||

| Length | 1200 mm | ||

| Thickness | 50 mm | ||

| Price: | 199 r. per sheet | ||

Plates Penoplex Wall 100 | Minimum material strength | 0.25 MPa | Due to the maximum possible thickness of the slab, this material is suitable for use in the most northern regions. |

| Water absorption in 24 hours, no more | 0.4% by volume | ||

| Width | 600 mm | ||

| Length | 1200 mm | ||

| Thickness | 100 mm | ||

| Price: | 365 r. per sheet | ||

Plates Penoplex Wall 50 | Minimum material strength | 0.12 MPa | The cheapest of the entire range, the standard plate is suitable for both external and internal insulation. |

| Water absorption in 24 hours, no more | 0.5% by volume | ||

| Width | 600 mm | ||

| Length | 1200 mm | ||

| Thickness | 50 mm | ||

| Price: | 105 r. per sheet | ||

Plates Penoplex Pitched roof 100 | Minimum material strength | 0.3 MPa | The ratio of the size and price of penoplex in this case is optimal for harsh conditions, when damage is possible, as well as frequent temperature changes. |

| Water absorption in 24 hours, no more | 0.4% by volume | ||

| Width | 600 mm | ||

| Length | 1200 mm | ||

| Thickness | 100 mm | ||

| Price: | 143 p. per sheet |

Article

Insulation "Penoplex" is one of the most used extrusion finishing materials for thermal insulation of structures of buildings and structures. Thanks to excellent technical parameters it is often used in the construction industry.

Types of "Penoplex"

"Penoplex" is one of the types of extruded polystyrene foam. The high technical characteristics of this material are determined by its cellular structure. Cells ranging in size from 0.1 to 0.2 mm are evenly distributed in the material, which gives it strength and a high degree of thermal insulation.

Depending on the type of surface to be insulated, there are several types of "Penoplex":

- "Penoplex roofing" is used for thermal insulation of pitched or flat roofs.

- "Penoplex wall" for insulation of internal and external walls of buildings.

- "Penoplex foundation" is used in the construction of foundations, basements, basements, cellars.

- "Penoplex comfort" - technical characteristics of an improved type are intended for use in houses and apartments.

- "Penoplex base" for insulation of industrial and civil structures.

- Penoplex 45 is the most specific type, it is used for thermal insulation of the runway at airfields.

The most versatile of them is Penoplex Comfort.

"Penoplex comfort": technical specifications

Thermal insulation sheets have L-shaped edges, which greatly facilitates the installation process, and also reduces heat loss.

- The density of "Penoplex Comfort" is from 25 to 35 kg / m 3.

- Compressive strength - 0.2 MPa.

- Water absorption - 0.5% of the total volume for 28 days.

- Combustibility category - belongs to the G4 group.

- Thermal conductivity coefficient - 0.03 at 25 degrees.

- Vapor permeability coefficient - within 0.007-0.008.

Plates "Penoplex comfort" are made in thickness from 2 to 12 cm, in length - from 120 to 240 cm, in width - 60 cm. For internal insulation sheets with a thickness of 2 cm to 10 cm are used, for exterior finish- 8-12 cm, roof - 4-6 cm.

According to the parameters of Penoplex Comfort, the technical characteristics allow its operation in conditions temperature regime from -50 to +75 degrees.

Advantages

This universal heater has a lot of advantages:

- It is not affected by fungi and mold.

- High water resistance.

- When wet, the plates do not rot, unlike mineral wool.

- High density material, does not crumble or crack like foam.

- Fairly light weight.

- Little susceptible to deformation, as it has a large coefficient of bending and compression.

- Very low thermal conductivity.

- Low moisture absorption coefficient.

The density of the foam is much higher than the foam. It does not deform under loads, it is easily cut with a knife. Because individual elements fastened to each other very tightly, the resulting design is very resistant to mechanical stress. The composition does not contain dust and fine fibers, which makes the Penoplex installation process clean enough.

Flaws

But with so many advantages, this material also has a number of disadvantages. At high temperature Insulation "Penoplex" emits harmful substances and collapses, in the first days after installation there is a strong smell in the room. It has very low vapor permeability. The action of ultraviolet radiation is detrimental to Penoplex - it is imperative to create a protective layer. The ignition of the material occurs with the release of a large amount harmful substances and the formation of acrid smoke. "Penoplex comfort" has very low sound insulation performance.

Oil paints and solvents can easily destroy the structure of the material, it will lose its thermal insulation properties. But to the colors on water based, salts, alkalis, lime, cement "Penoplex" is neutral.

Mounting technology

The task of how to sheathe a house with Penoplex comfort is solved in several main stages:

- Preparatory.

- Direct installation of insulation.

- Finishing the surface of the insulation.

Initially, it is necessary to prepare the surface that will be insulated. It is leveled, excess mortar is removed, exfoliating pieces of the structure. If previously stained, then paints and varnishes should be completely removed. Places of formation of fungus, mold or moss are cleaned and treated with bactericidal solutions. Unplastered block or brick structures must be primed or plastered. The prepared substrate must be absolutely dry.

Due to the exact geometric dimensions, installation is carried out according to the assembly principle of the designer. Insulation sheets are glued to the surface with special adhesive compositions. Glue is applied to the surface of the "Penoplex comfort" board. Additionally, the thermal insulation structure is reinforced with building dowels. Special attention it is worth giving fastening in the area of openings, joints of sheets and in the corners of the structure.

To protect the insulation itself, plastering, finishing with facing facade materials, roofing. With thermal insulation internal surfaces be sure to use a vapor barrier insulation.

Features of finishing individual structures

In city apartments, in order to make the most practical use of the available space, balconies and loggias are often insulated. In this case, indoors, in order to save space, Penoplex comfort insulation 2-5 cm thick is usually used. This option can be used in pre-glazed loggias, preferably with double or triple glazing. On device external thermal insulation it is possible to use thicker sheets - up to 10 cm.

When insulating floors, sheets can be laid without a frame device. In houses, if there is no basement, Penoplex Comfort is laid out directly on the ground surface. Plates with a thickness of 3 cm to 10 cm are used. The site prepared for laying must be flat and dry.

Insulation of foundations with "Penoplex comfort" can be carried out directly on the waterproofing layer, without additional mechanical fastening of the structure. The slabs are installed with an overlap of rows, they should protrude 40-50 cm above the upper level of the foundation. Then the foundation is backfilled. This material is used for any type of foundation.

Application area

"Penoplex comfort" is intended for use in the insulation of foundations, basement floors, facades of houses, roofs, as well as internal thermal insulation in private houses or apartments. It is also often used for wall insulation on balconies and loggias, in garages and outbuildings. IN suburban construction it is used as thermal insulation of rooms with high humidity: saunas, baths, pools, basements.

When using underfloor heating in the system, it is necessary to lay heat-reflecting materials under the Penoplex insulation to reduce heat loss.

Certification

The production of the Penoplex Comfort material in Russia is carried out by LLC PO Penoplex. Certificates have been made for this thermal insulation material fire safety, fire roofing safety, environmental certificate, certificate of conformity to GOST. Thermal insulation tests for durability, acoustic tests for sound insulation were carried out. The certificate of conformity received for the Penoplex Comfort insulation sanitary standards confirms the safety of the use of this material and for interior decoration premises.

Throughout the warranty period of the Penoplex Comfort insulation, the technical characteristics of this material remain at high level. The plates do not crumble, do not crack, retain their original density. Durability of 50 years is one of the most significant advantages of this material.

We will send the material to you by e-mail

By doing thermal insulation works are used . These materials can significantly reduce heat dissipation into the surrounding space. Penoplex is especially popular, the technical characteristics of which make it possible to use it in various regions. By choosing plates of suitable thickness, you can ensure a sufficient level of thermal insulation of walls, floors, ceilings. Let's talk about this heater in more detail.

Penoplex - universal heat insulating material

Penoplex - extruded polystyrene foam, which got its name from the same name trademark. It belongs to the category of the most popular thermal insulation materials due to its unique technical characteristics and reasonable cost. It is actively used for insulation various surfaces in the construction and reconstruction of residential buildings and public buildings.

During the production process, polystyrene granules are foamed under conditions high pressure and temperature. Carbon dioxide and light freon act as a catalyst for the process. The finished mass, similar to cream whipped with a mixer, is blown out through special nozzles of the extrusion unit. Here freon evaporates, and the resulting voids are filled with air.

This production technology makes it possible to obtain a finely porous material, inside which adjacent cells with air are isolated from each other. The diameter of the air pockets does not exceed 0.1-0.2 mm. Due to the uniform distribution throughout the volume of the material, the manufacturer provides the required level of properties. The material has high strength and shows excellent thermal insulation characteristics. With the selection of material of sufficient thickness, the desired effect can be achieved.

For your information! Penoplex 50 mm is used in the insulation of buildings, roads, runways.

The manufacturer offers various types of thermal insulation material:

- Foundation able to withstand significant loads during operation. The minimum thickness of the plates is 50 mm. If necessary, you can order a thicker heat insulator if the building will be operated in the northern regions;

- Roof having special form facilitating the process of laying tiles. With the help of heat-insulating material of this type, it can provide high-quality protection of the roof from external cold. In this case it becomes possible use attic as living quarters;

- Comfort. Penoplex thickness of 30 mm, as a rule, is sufficient for high-quality thermal insulation of the walls of a residential building or loggia;

- Wall. Suitable option for wall insulation inside and outside the job. The thickness of the material can be 20-50 mm. If the work will be done from the inside, it is better to choose a thinner material. For the facade, it is worth ordering thicker plates.

Attention! The thickness of foam 10 mm is not enough for high-quality insulation of the walls of a building operated in winter. Thicker plates should be chosen, for example, 70 mm.

Related article:

The main technical characteristics of penoplex for the foundation

In terms of technical characteristics, Penoplex GEO corresponds to the old type Penoplex 35, the production of which was carried out without flame retardant. It is used for thermal insulation of surfaces, the fire resistance of which is not subject to increased requirements. The material belongs to group G4.

The main area of application of the heat insulator is the insulation of loaded structures, followed by the application of a protective layer. The material is in demand when constructing a cement-sand screed, thermal insulation of the foundation, floor, building basement or garden paths. The slabs become a reliable protection for, providing groundwater drainage and reducing their impact on underground structures of buildings.

For your information! A bioresistant durable insulation is in demand when building a shallow foundation on heaving soils.

The minimum thickness of foam plastic Foundation is 50 mm. If necessary, you can also purchase plates with a thickness of 80 mm. Plates are able to withstand significant loads throughout their entire service life. Their strength with a linear deformation of 10% is 0.25 MPa. Water absorption by volume for 4 weeks does not exceed 0.5%. The insulation is able to last more than half a century, including when operating in the harsh climate of the northern regions.

The main technical characteristics of comfort foam

This type is universal. Technical characteristics of Penoplex Comfort 50 mm allow thermal insulation of many surfaces. With its help, simultaneous insulation of the roof, basement, floor and foundation of the building is carried out. The low level of water absorption, not exceeding 0.5% for 4 weeks, makes it possible to use Comfort for insulation, a pool or. Thermal insulation of other objects, the operation of which is carried out in conditions of high humidity, is possible.

Tight docking of elements among themselves contributes to the stability of enclosing structures. Not subject to biodegradation. You can not be afraid that insects will appear inside the heat-insulating material, which will destroy the structure of the plates from the inside. Able to serve more than 50 years, retaining its technical characteristics. It can be operated in various regions, including the northern ones.

The material is quite dense, and therefore does not sag when attached to a vertical structure. It is necessary to correctly install and securely protect all plates. Density of Penoplex Comfort is regulated by TU 5767-006-54349294-2014. When cut, it does not crack or crumble. The compressive strength depends on the thickness of the plates: if less than 60 mm - 0.12 MPa, more than 70 mm - 0.18 MPa.

Attention! Finishing must be carried out on the insulated surface.

Applying the finishing layer allows you to:

- Give the penoplex an aesthetically attractive appearance. The material itself does not allow the formation of a beautiful surface that could be exploited without additional processing;

- Prevent discolouration of plates;

- Avoid material degradation.

Main technical characteristics of penoplex Roofing

Plates Penoplex Roofing are in demand in the construction industry. The material of characteristic orange color is produced with a density of 35 kg/m3. Allows you to form a rigid and moisture-resistant heat-insulating layer with low weight. Can be used for roofing various types, thermal insulation of building facades, floors and walls of buildings being erected and reconstructed, basements, laying of engineering communications.

The material is classified as moderately flammable. During combustion, it emits a large amount of smoke. This feature should be taken into account when choosing a heater for a dwelling.

A special connection of the tenon-groove elements makes it possible to form a homogeneous layer that does not have cold bridges. Due to the refusal to overlap adjacent elements during the installation process, it is possible to optimize the thickness of the heat-insulating layer being arranged and more rationally manage the free space.

Water absorption by the volume of the plates does not exceed 0.5%, and therefore the heat-insulating layer practically does not absorb moisture. High strength makes it possible to withstand a significant load that the heat-insulating material may be subjected to during the installation of plates and the subsequent operation of the insulated object.

If you have to insulate the facade of the building, instead of foam roofing, you can use special kind heat insulator. Its characteristics are initially adapted for this type of work. The price of Penoplex insulation for walls outside the house is acceptable for many. It depends on the thickness of the plate. For you can purchase material with a thickness of 20 mm, for a residential building - 50 mm.

Extruded polystyrene foam: technical characteristics and price of quality boards

This type of thermal insulation material became available to users more than half a century ago. Extruded polystyrene foam, sometimes referred to as extruded polystyrene foam, immediately became a universal insulator that is in demand for a variety of jobs. Manufacturers offer sheets standard size which can be transparent or colored. Sheet plastic, due to its special structure and unique production technology, demonstrates high performance during operation.

Attention! Before buying, you should find out the required characteristics of insulation. Penoplex must meet the requirements.

The technical characteristics of 50 mm foam plastic may vary slightly depending on the type of material. However, in most cases they vary within a fairly narrow range.

The technical characteristics of penoplex 35 include:

- Low water absorption capacity. The main advantage of this heater. The heat insulator absorbs water molecules only on sections, since air cells are open in these zones;

- Low thermal conductivity. On average, this indicator is 0.03 W/m·S;

- Versatility. The manufacturer offers material of various thicknesses, making possible insulation many surfaces. It is used for thermal insulation of walls, foundations, loggias and balconies;

- Low vapor permeability;

- Long period of operation. Penoplex is able to withstand repeated freezing / thawing without loss of basic performance. On average, such material can last about 50 years;

- High strength. During operation, the insulation withstands a significant load and pressure due to the presence of tiny air bubbles in the material that prevent compression of the material;

- Ease of installation. The material can be easily cut with a sharp knife, giving the elements the desired shape. The cut site does not crumble. Installation work can be performed all year round, as the heat insulator is not afraid of exposure to UV rays and high humidity. Plates can be fixed at any time of the year;

- Ecological safety. In the production process of insulation, freon is used, which does not have a negative impact on the atmosphere. During operation, the insulation does not emit substances that can have a negative effect on the human body;

- Fire safety. The material is resistant to burning;

- Minimum chemical activity and biological inertness. By doing construction works a large number of substances with increased surface activity are used. Only a few are capable of interacting with penoplex. The heat insulator does not rot or decompose.

Penoplex is not the only extruded polystyrene foam that can be purchased for home insulation. Similar technologies are used by other manufacturers, offering high-quality insulation.

The technical characteristics of Technoplex are somewhat different from those of Penoplex. This contributes to the change in the composition of the raw materials used. A certain amount of graphite is added to the composition of the mass subjected to extrusion. The result is a highly effective insulating material resistant to water.

Technoplex absorbs noise well and has a long service life. At the same time, it is somewhat inferior in strength. Works well at fairly low temperatures typical for the Far North and has more low level water absorption. Only 0.2%. However, when buying this type of thermal insulation material, you will have to pay more. Considering that a large amount of material is usually required for wall insulation, this factor can be decisive when choosing.

Video review: extruded polystyrene foam

Penoplex sheet sizes: how to choose the right one?

A special technology for the production of extruded polystyrene makes it possible to form a material with a unique structure that ensures high strength of the boards and guarantees unique thermal conductivity. As a rule, a material of small thickness is used for thermal insulation of various surfaces. When choosing suitable option should follow the manufacturer's recommendations.

If it is necessary to carry out the insulation of an object, the operation of which will be carried out in a temperate climate, you can use plates with a thickness of 35-50 mm. Their technical characteristics will provide the necessary level of thermal insulation of walls or roofs.

For regions located in cold climatic zones, it is worth purchasing a 70 mm thick insulation. Even if the frost is more than -30°C, a comfortable temperature will be maintained inside the building.

For foam boards, the dimensions are standardized. The manufacturer offers plates with a length of 1.2 m and a width of 0.6 m of various thicknesses. The last dimension can be in the range of 20-150 mm. The choice of a suitable thickness should be made taking into account the operating conditions of the surface to be insulated.

Before buying a thermal insulation material, you should perform a calculation required amount. To do this, you need to know the area of \u200b\u200bthe insulated surface. You should definitely find out by choosing 50 mm foam, how many m² are in the package. This will depend on the number of packages that you need to purchase. Sheets are also sold individually, and therefore the missing quantity can be purchased additionally.

For those who buy penoplex, how many pieces per package matters. This indicator depends on the thickness and type of plates. For a material with a thickness of 50 mm, the ratio is as follows:

| Type of insulation | Image | The number of plates in the package, pieces |

|---|---|---|

| Comfort |  | 7 |

| Wall |  | 10 |

| Foundation |  | 8 |

Penoplex price 50 mm: the main factors affecting the cost

Penoplex sizes and prices are directly dependent. The thicker the plate, the more you have to pay for it when buying a heater. In addition, the type of material has a significant effect. In the production process, certain components are introduced into the composition of the raw materials used. This inevitably affects the cost of the produced material.

Advice! To find out how much penoplex costs, just tell the seller required thickness insulation and its type.

If you are interested in the price for a foam sheet of a certain type and thickness, you can focus on the following data:

| Name | Sheet thickness, mm | Number of sheets in a package, pcs | Sheet cost, rub. |

|---|---|---|---|

Comfort Comfort | 20 | 18 | 77 |

| 30 | 12 | 115 | |

| 40 | 9 | 153 | |

| 50 | 7 | 187 | |

| 100 | 4 | 385 |