One of the most popular options can be called structures with a frame made of steel angle or galvanized pipes. It will be absolutely easy to build a garden gazebo with your own hands from this material. The only thing is that you need to have a welding machine on hand.

Building a small, lightweight metal gazebo with your own hands is actually very simple.

Lightweight structures with a metal frame are usually installed in the garden near small country houses. Their walls or parapets can be wooden or polycarbonate. A device of this design will save a lot of money, since it is usually very inexpensive.

On a note: An exception in this regard are options with forged parapets and roof cornices. There are a lot of such gazebos and they are usually installed in the yards of large residential buildings.The advantages of metal structures, among other things, include a variety of designs and lightness. Often, the support for the frame is simply a frame welded at the bottom. It will be completely easy to transfer such a summer gazebo to another place on the site, if necessary.

The metal structure can have a very beautiful unusual design.

There are only two drawbacks to this variety. Firstly, the metal rusts, and secondly, steel tends to get very hot in the sun.

wooden structures

Arbors made of wood - the most common variety. You can build such a structure on a frame made of timber. In this case, the walls are usually sheathed with a board. A frame gazebo is quite simple to build and at the same time a beautiful and elegant design. You can build such a courtyard "house" both in the country house and in the courtyard of a residential building.

The easiest way to build a garden gazebo on a wooden frame

Home-made chopped gazebos are often erected near log buildings. Not bad, this solid massive option looks in the yards of concrete country cottages. A large paving arbor can also look no less solid.

In the courtyard of a large cottage, it is best to build a chopped street "house"

Using wood is a good answer to the question of how to build your own gazebo with the best performance. The main advantages of structures made of this material include, first of all, environmental friendliness and very good heat transfer.

Brick gazebos

Usually built from brick winter gazebos. Those who are wondering how to build a beautiful gazebo should consider this particular option. form brick structures, due to the characteristics of this material, can have the most diverse. Their main advantage is solidity and durability, the disadvantage is high cost.

To build a brick gazebo means to get the most durable construction

Having decided on the material, size and shape, you can proceed to the actual construction of the gazebo. It should be collected independently, strictly adhering to certain technologies. Only in this case it is possible to build a reliable and durable structure. For example, similar to these:

Construction technology step by step

So, let's see how you can assemble this useful design yourself.

How to make a project and drawings

To begin with, let's figure out how to draw up a project in order to build a gazebo with your own hands. Drawings must be drawn in compliance with all proportions and dimensions. structural elements. You also need to think about what building materials will be needed, and calculate their quantity.

Advice: Usually a garden gazebo is installed behind the house, not too far from it. In this case, it will be more convenient to use it. In addition, this arrangement facilitates the summing up of all necessary communications.

Scheme of a rectangular structure with a hipped roof

Foundation construction

Since wood is a rather light material, it is not necessary to build a very powerful foundation under such an arbor. It will be enough to build an inexpensive columnar. The method of erecting such a structure in stages:

- At the corners of the future gazebo and along the line of the walls, holes are dug under the pillars.

- A layer of rubble is poured and compacted on their bottom.

- Further, a roofing material sewn into a tube is installed in the pits.

- A small reinforcing mesh is inserted into this formwork.

- Then everything is poured with concrete.

How to build a gazebo with your own hands. Foundation pillars can be poured into roofing material formwork

Advice: It is advisable to pour an anchor bolt into each pillar from above. The bottom trim of the frame will be attached to them.How to build a gazebo in the garden: frame assembly

The lower trim is made from a bar 100 * 100mm. In the corners, the bars are connected in a “half-tree” way. Inside the strapping in the middle across the corners, a log is attached under the floors. A bar 100 * 50mm is suitable for her.

The assembly of the frame continues with the installation of racks. They are also made from a bar 100 * 100mm. The corners are installed first. In their upper part, you need to make cuts 50 * 100mm under the boards of the diagonal bundle. The latter are connected "in half a tree" crosswise.

Photo of building a gazebo with your own hands. Ready timber frame

Important: In order for the bundle to come out strong, at the intersection of two boards, it is imperative to fill the bars of a small section (in each of the four corners).Next, the bundle is fixed on the poles by inserting the boards into the cuts of the corner support posts, and fastened with nails. Then, around the perimeter, the upper harness is mounted. At the next stage, handrails from a 100 * 50mm board are stuffed on three sides of the structure at a height of 90 cm from bottom strapping.

How to build a gazebo. For the railing, a board 100 * 50mm is used

This is how the rectangular frame is assembled. By the way, the question of how to build a hexagonal gazebo or an octagonal structure, for those who understand the principle of its construction, should not be. In this case, everything is done in much the same way, only the corners and, respectively support pillars there will be more.

Installation of the truss system

Next, consider how to assemble the roof frame of the gazebo. Do-it-yourself installation of the truss system begins with the manufacture of a central support column. A timber with a section of 100 * 100mm and a height equal to the height of the future roof is suitable for it. It needs to be cut in the form of an octahedron and cut into it under two rafter legs. The latter are connected “in half a tree” at an appropriate angle, inserted into a column and fixed with nails.

How to build a gazebo with your own hands. Photo of the process of assembling the truss system

Important: The length of the rafters should be such that after installation a cornice overhang is at least 40 cm long.The assembled structure is lifted to the roof. It can be installed on corners and nails. At the next stage, the remaining two diagonal rafter legs are mounted. Then, four more intermediate rafters will need to be raised and fixed to the roof.

Below we suggest you watch a video on building a gazebo with your own hands. Perhaps it will help someone understand the process of assembling the frame and rafter system of a hipped roof better.

Railing and roof sheathing

The railing can be sheathed with clapboard or a regular edged sanded board. On the roof, under the roofing material, a continuous crate is made. It is best to stick a flexible tile on it.

No such owner land plot who would not dream of equipping it in the best possible way, equipping cozy places for outdoor recreation. traditional element landscape design is a gazebo, but there are a lot of varieties of these light buildings, and therefore it can be difficult to decide on the choice of the desired model, as well as decide on its independent construction without even a theoretical background.

The question of how to build a gazebo with your own hands has always been and remains relevant, as more and more urban residents are moving out of town for permanent place residence or acquire summer cottages. When starting the construction of any building, first you need to decide how it should look, which is why it makes sense to consider several design options for gazebos that you can easily raise yourself.

These summer buildings may differ in style and design, size, and material of manufacture. And the optimal model is selected depending on the size and design of the site, as well as the personal preferences of its owners.

Lattice gazebos

Gazebos sheathed with grating along the diagonal of the walls are quite popular for summer cottages and private territories, as they give good shade, and at the same time do not interfere with the flow of fresh air. An important condition to choose the installation site of such a building is a closed space where there is no draft, otherwise the gazebo will be built in vain, since it will not be very comfortable to be in it. If country cottage area not yet planted with trees and there is no area that is not blown by the winds, it is recommended that the lee side of such an arbor be made “deaf”.

Such gazebos are most often built so that over time, stems of climbing trees can climb along the lattice walls. perennials, which will create protection from the wind and fill the space under the roof with constant freshness. If planted around the building flowering plants, then, relaxing in it on a hot day or a cool evening, you can enjoy your favorite aromas.

The disadvantage of such an arbor, until it is entwined with vegetation, lies in its openness and exposure to jets of oblique heavy rain, so it will not work to hide in it from such bad weather.

Another version of an already larger gazebo with two rear “blind” walls that completely cover its interior from the eyes of neighbors also has a lattice sheathing - in the lower panel part and under the roof itself. After climbing plants, planted around the building, will rise along the lower crate, from it you can stretch the ropes to the finish under the roof at the right distance from each other, thereby forming "windows" framed with greenery and flowers.

The roof of the shown gazebo is covered with transparent polycarbonate having green tint, which gives the inside a calm, eye-pleasing lighting. This factor will certainly contribute, in combination with fresh air, to the most comfortable rest.

Due to the fact that the gazebo has enough big sizes, it is raised above the ground by about 200 mm on a columnar foundation. This will help keep the floor boards from the harmful effects of moisture, as the space under the building will be constantly ventilated.

Small original gazebo

This original design summer vacation spot will not leave guests indifferent, and the residents of the house will be convinced more than once of the comfort of such an arbor. The building has a simple design with shed roof, but it is quite roomy, and it may well accommodate a couch and a table. If desired, the size of the gazebo can be calculated for a specific set of furniture. Deaf rear walls buildings will close the space from the wind, and round entrances in the other two walls will contribute to the ventilation of the room. If desired, round openings can be equipped with waterproof or mosquito-proof curtains, which will allow you to stay in the gazebo in any weather or even stay in it at night when the house gets too stuffy.

Arbor - summer house

This arbor well deserves the name " summer house”, which can be used for living in the warm season. For example, if you plan to build an economy version of a house on a summer cottage, then this design is perfect for this purpose.

You can build such a structure on the site of a private house, since in the summer you want to spend more time outdoors, and thanks to big windows and a door that opens wide, there will be plenty of it in the room.

To build a similar version of the gazebo, more costs will be required, since the design includes windows and glazed doors. But it is thanks to these elements that you can achieve complete comfort for relaxation both in the daytime and at night, and in any weather.

Arbor - pergola

Pergola came to Russian landscape design from Italian style decoration of gardens, where, in accordance with the peculiarities of its design, it could serve as a canopy, arch or extension. Thanks to domestic improvements, this kind of garden structures has become a real decoration of many summer cottages and territories of private houses.

The pergola is installed in order to create a support for climbing plants, as protection from the hot sun for a certain place on the site, a gazebo for relaxation, or simply as decorative element garden. Therefore, the model of this building must be chosen depending on what tasks will be assigned to it, but most often it is used for several purposes at once.

The first photo shows a covered pergola installed as a canopy over a recreation area. In fact, she created an open gazebo, under which fit massive table, quite sufficient for a large family to gather behind it, as well as a grill built into the back wall. The convenience of the design lies in the fact that under the covered space you can not make a foundation - it will be enough to lay paving slabs or lay garden plastic panels on top of the soil. The basis will have to be done only for the supporting pillars.

In this case, the pergola performs three functions at once - a passage arch, supports for a rose bush and gazebos, which successfully complement each other. The benches in this corner of the rest are located at such a distance that a table can easily fit between them, therefore, in such cozy place It will be great to spend evenings with family tea drinking. In addition, a gazebo entwined with greenery is a great place to relax on a hot day, where you can hide from the sun, sitting comfortably with a book.

This version of the pergola is designed as a support for climbing plants that will cover a small gazebo, which is sure to become a favorite place for some family members who love privacy. For this version of the gazebo, it is also not necessary to arrange a foundation, due to its low weight, which significantly reduces the overall amount of work. The roof can be left open, as is the case with the classic pergola design, or it can be covered with light roofing material such as ondulin or plastic slate.

Construction of garden arbors

Having prepared all the necessary tools, you can purchase building materials for the selected gazebo model and proceed to construction work.

Required Tools

When building any model of a gazebo, you cannot do without special tools and fixtures, so you will need to prepare for work:

- Circular saw, electric jigsaw and hacksaw.

- Miter box for sawing structural elements at an angle.

- Electric drill and a set of drills.

- Screwdriver.

- Hammer, tape measure, folding rule, construction square, pencil for marking.

- Construction level, plumb.

- Pincers and cutters.

- Drill for making holes in the ground for the installation of foundation pipes.

- Staircase.

Rectangular gazebo

A rectangular gazebo can be called a traditional version of a summer building, since quite often such a design is chosen for installation on a site. It should be noted that such a gazebo is quite comfortable to use and aesthetic in appearance. In addition, if desired, you can make your own adjustments to the design, for example, close one of the walls completely or raise the fence to a higher level.

The building does not have too much mass, so it is installed on a columnar foundation or even just on well-packed soil, reinforced with a layer of rubble, which also provides good drainage.

The depth of laying the foundation, if provided, depends on the characteristics of the soil in a particular area.

Since wood in outdoor conditions will constantly be negatively affected by: ultraviolet rays, moisture, wind, etc., it is recommended that the finished parts be carefully treated with antiseptic, water-repellent compounds. Such protection will protect the material from decay, from insects, and maximize the durability of the building.

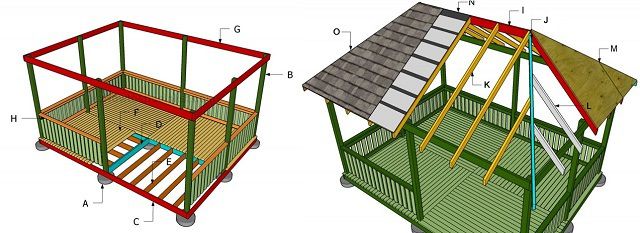

The diagram below shows a drawing of a gazebo. All its details are assigned letter designations- they are listed in the table necessary materials. Further, in the course of the description of the assembly process, drawings will come across in which the dimensions are in inches. To convert to metric: 1 inch = 2.54 cm or 25.4 mm.

For the construction of this gazebo, the following materials will be required, which have letter designations on the diagram, the dimensions on the diagrams are given in inches: 1 inch \u003d 2.54 cm or 254 mm.

| Necessary materials | Dimensions of parts, mm | Quantity, pcs. | |

|---|---|---|---|

| Pillar foundation (A) | Asbestos concrete pipes | Ø 200÷250, length 1200÷1500 | 9 |

| Racks (B) | wooden beam | 100×200×3250 | 8 |

| Bottom rail of the structure (C) | bar | 100×150×3600 | 2 |

| 100×150×4725 | 2 | ||

| Intermediate beams of the floor frame (D) | bar | 100×150×1655 | 4 |

| 100×150×4550 | 1 | ||

| 100×150×2240 | 2 | ||

| Floor joists (E) | bar | 50×150×1750 | 10 |

| 50×150×2325 | 8 | ||

| Floor decking (F) | Boards | 50×100×2400 | 40 |

| 50×100×1800 | 52 | ||

| Upper harness (G) | bar | 50×150×3600 | 2 |

| 50×100×4725 | 2 | ||

| Gazebo fence (H) | Boards | 20×100×675 | 92 |

| Beam (tying) | 50×100×2230 | 9 | |

| 50×100×1630 | 12 | ||

| Roof ridge (I) | bar | 50×150×2445 | 1 |

| 50×100×1930 | 2 | ||

| Diagonal rafter legs with a 60 degree cut at the ends (J) | bar | 50×100×2760 | 4 |

| Ordinary rafters (K) | bar | 50×100×2450 | 10 |

| Rafter legs with ends cut at an angle of 34 degrees (L) | bar | 50×100×1375 | 4 |

| Rafter legs with ends cut at an angle of 45 degrees (L) | bar | 50×100×800 | 4 |

| 50×100×1360 | 4 | ||

| Base for roofing material (M) | Plywood | 15×120×2400 | 11 |

| Roof waterproofing material (N) | Ruberoid or membrane | based on 27 m² of roofing, with the necessary margin | |

| Roofing material (O) | bituminous tiles | ||

| Consumables | Nails, screws and screws. |

Work on the construction of this gazebo occurs in the following order:

| Illustration | |

|---|---|

| The first step is marking the territory at the site chosen for construction. To do this, around the perimeter future construction pegs are installed on which the rope is stretched and fixed. The corners of the marked area must be measured very accurately, they must be perfectly straight. To make sure that the markup is correct, it is necessary to measure the diagonals of the rectangle and, if necessary, make adjustments. The diagonals must be equal to each other. The presented illustration shows an example of calculating and marking a place for construction, however, with different sizes, but the principle does not change from this. |

| Next, holes are drilled for installing the pipes of the columnar foundation. Their depth should be more than the level of soil freezing by 150 mm. The height of the pipes above the ground can be different, depending on the desire of the master to raise the gazebo to a certain level. If necessary, the excess of their height can be cut off with the help of a grinder. On average, for the base for the gazebo, the pillars go deep into the ground by 500 ÷ 700 mm. Having installed the pipes in the drilled "nests", they are set exactly vertically in level and the soil around them is strengthened with crushed stone and soil, which is well tamped. Then, the pipes are filled with cement-gravel mortar for ⅔ of their volume. |

| The next step is to install rack bars in the foundation pipes. It is recommended to pre-treat the lower part of the beam with bituminous mastic. The beam is set according to the level (plumb). Inside the foundation pipe, it can be supported with fragments of rubble or wooden supports can be installed, securing them to stakes driven into the ground. Then the pipes are supplemented with concrete mortar to the top, and this structure is left until completely solidified. |

| After the mortar has hardened, before fixing the lower trim beam, it is recommended to vertically installed bars lay waterproofing material, for example, roofing material. Further, the beam prepared in size for the lower strapping is fixed in the lower part on the vertical posts with self-tapping screws 90 mm in size. To avoid splitting the timber, before screwing in the fasteners, holes are drilled for them 2 mm smaller than the diameter of the self-tapping screw. When fixing the strapping, you should carefully control the horizontal installation of the timber using the building level, since this will depend on correct location other building elements. |

| After the strapping beam is fixed, intermediate beams are installed and fixed, which will divide the area of \u200b\u200bthe floor of the gazebo into four parts and give the necessary rigidity to its structure. |

| The next step is to install logs on the strapping and intermediate timber. To increase the strength of the floor, the logs are fixed in such a way as shown in the diagram. Logs are installed in 400 mm increments, ideally horizontally, according to pre-made markings. |

| Fixing the log is carried out on special metal supporting elements, which are screwed with self-tapping screws 50 mm long to the inside of the strapping beam and floor beams. Moreover, they must be fixed strictly at the same level, otherwise the floor will turn out to be uneven. |

| Supporting element for the installation of a beam-crossbar. These items are produced different sizes in height and width. |

| Further, flooring is made from floorboards on the logs. If the prepared base is reliable and even, then laying the boards will not be difficult at all. The boards are fastened to the logs with nails or galvanized self-tapping screws 60 millimeters long. The heads of fasteners should be flush with the main surface of the board or recessed into the wood by 1.5 ÷ 2 mm. Since the building will be located on the street under the influence of moisture, the wood may well swell, therefore it is recommended to leave a gap of 3 ÷ 5 mm between the boards. Such slots will also contribute to the timely removal of water and moisture from the boards and their rapid ventilation. |

| When the floors of the gazebo are ready, the upper trim of the structure is fixed on top of the racks. It is also fixed with self-tapping screws 90 mm long, on the outside of the timber. To check the horizontalness, a building level is used. |

| Having a ready-made, well-mounted frame of the gazebo box, you can proceed to install the fence. The first step in the installation of this part of the building is the installation of horizontal bars, fixed between the racks. They are installed in two rows, one of which runs along the bottom edge of the racks, and the other rises to the level planned by the project. The crossbars are set according to the level and fixed on the racks with self-tapping screws. Additionally, they can be reinforced with metal corners, which are attached to the crossbars from below, and then screwed to the uprights. |

| Further, balusters are mounted between the rungs. These can be ordinary sanded boards, as presented in this project, or round classic balusters can be carved from a bar, which, if desired, is given its own configuration. Flat balusters are fixed on the lower transverse beams with nails or self-tapping screws screwed from the inside of the gazebo from top to bottom. In the upper part of the balusters are fixed through the crossbars. If round balusters, machined from a bar, are chosen, then they are mainly mounted, both from above and from below, on glued dowels. After completing their installation, top rails railings are fixed. They are first glued with wood glue, and then fixed with self-tapping screws, sinking their hats into the wood. |

| Any roof for the gazebo can be chosen: - shed, for which it will be necessary to raise the front part of the building, fixing short racks of 200 ÷ 250 mm on the upper trim; - gable or, as presented in this project - four-slope hip. You need to start installing such a roof with the creation of a truss system consisting of diagonal and middle rafters and a ridge beam. The rafters can be prepared at the bottom, and then raised to the top harness. To simplify your task, you can temporarily fix the rafter legs and the ridge beam in the desired position until the final fastening by installing supports from the floor of the gazebo to the ridge. |

| The fixed initial frame of the truss system begins to be strengthened from the hip sides - rafters (spiders) are installed and screwed on them at a distance of 600 mm from each other. The jocks on the hips begin to be fixed from the center of the triangle. |

| The next step is to fix the rafters on large, trapezoidal slopes, starting from the middle of the ridge beam, and then moving to the diagonal rafters. The upper side of the rafters is fixed on the ridge beam, and the lower side - on the beam of the upper trim of the gazebo structure. |

| If a light material is used to cover the roof, for example, bituminous or plastic wave slate or polycarbonate, then it is immediately attached to the crate, which is made of boards (for example, 100 × 25 mm), installed with the desired step on the rafters, perpendicular to them. |

| In the event that the work will be carried out strictly according to the project being demonstrated, using bituminous tiles for covering, then a solid crate of plywood 15 mm thick is first fixed to the rafters, pre-cut with circular saw. The fixing of this material is carried out with self-tapping screws 30 mm long with a step between fasteners of 150 mm. A gap of 1 ÷ 1.5 mm must be left between the sheets for the thermal expansion of the material, in order to avoid its warpage. |

| A waterproofing material is laid on top of the plywood - it can be roofing material or one of the types of modern membrane materials. Waterproofing sheets are mounted from the eaves in horizontal strips, overlapping each top sheet on the one below. The waterproofing is fixed with staples and a stapler. On top of the waterproofing, starting from the eaves, is mounted shingles. It should be installed according to the manufacturer's instructions. This diagram shows the installation of bituminous shingles - it will also require the creation of a crate. Sheet shingles can be laid directly on plywood prepared for this operation. |

| Upon completion of the installation of the roofing material and fixing the ridge element, a decorative strip is fixed along the eaves. |

After the gazebo is ready, adjustments are made small parts, such as sealing holes and recesses with wood putty or a composition of epoxy glue mixed with fine sawdust. The putty should dry well, after which all irregularities and roughness should be sanded with fine-grained sandpaper.

In the next step, all wooden structural elements are covered with stain and yacht varnish or paint, which will additionally protect the wood from external influences and give the gazebo a finished aesthetic appearance.

Pergola construction

A pergola can be a great place to relax around the pool, in the garden or as an extension to the house. This type of light building is sure to add a "zest" to the overall design of the site.

classic pergola

To build a pergola, fewer materials will be required than for a traditional gazebo, but if desired, the list can be supplemented with roofing and slats for diagonal cladding, as well as other elements.

The diagrams below show dimensions in feet and inches. In the table of materials, they are already converted to millimeters.

| The main structural elements of the pergola | Necessary materials | Dimensions of parts, mm | Quantity, pcs. |

|---|---|---|---|

| Column Foundation | Asbestos concrete pipes | Ø 200÷250, length 1200÷1500 | 4 |

| Cement, sand, gravel or crushed stone for filling pipes. | Depending on depth | ||

| Racks | bar | 100×100×2400 or 150×150×2700 | 4 |

| Embedded anchors (if needed) | 4 | ||

| support beam | Board | 50×150×3600 | 4 |

| Cross beams | Board | 50×150×3600 | 13 |

| crossbeams | Board | 50×150×3250 | 5 |

| Fixing support beams | screws | M6×175 | |

| mount for cross beams | self-tapping screws | 150 | |

| Crossbar fastening | self-tapping screws | 75 |

Work on the construction of a classic pergola is carried out in the following order.

| Illustration | Brief description of the operation to be performed |

|---|---|

| The construction of a pergola begins in the same way as any building - with the marking of the territory, after which holes are drilled in the ground for a columnar foundation. Hole diameter 250÷300 mm, depth 900÷1000 mm. At the bottom of the prepared pit, crushed stone is poured with a layer of 80 ÷ 100 mm thick and thoroughly compacted. |

| Asbestos-concrete pipes are installed in the pits, leveled, and then soil mixed with crushed stone is compacted around them. After that, the solution is kneaded, which fills the inside of the columnar foundation supports. |

| Pergola posts can be fixed to foundation piles in two ways. The first of them is their installation in poured concrete and fixation with spacers - until the solution has completely set. |

| Another option for fixing the racks on the foundation are embedded anchor metal holders with a leg, which are embedded in the concrete that has not yet hardened. |

| The holder embedded in the pole looks like this. |

| Concrete poured into asbestos-cement pipes should set well, it needs to be given at least three to four days for this. This time can be used to decorate the space that will be covered by the pergola elements installed in the form of a roof. |

| This area can be cleared of the upper fertile layer, covered with sand and cultivated with paving slabs. In addition to this option, there are other modern garden coverings that do not require time-consuming preparation of the base, but simply fit into the place chosen for them. |

| After the concrete has hardened, the pergola racks are installed and leveled to the building level. The racks are fixed in the holders using M6 screws with wide washers. |

| Support beams are pre-attached classical form- it may differ slightly in the shape of the slices. Further, they are fixed on racks in pairs. |

| Having fastened together two racks, the support beams give the structure the necessary rigidity. Their installation is carried out according to the scheme using bolts or self-tapping screws. They are installed in such a way that they protrude beyond the perimeter indicated by the racks by 250 ÷ 400 mm - the size of such an overhang will depend on the preference of the master or the owner of the site. |

| If you imagine this process schematically, it will look something like the one shown in this picture. |

| Having fixed the support beams, they are perpendicularly blocked by transverse beams, of which 13 pieces are provided in this project, and they are installed in increments of 300 mm. However, it should be noted that there may be more or less of them, and how much the space under the pergola will be shaded depends on their number. Boards for beams should be perfectly even, as their curvature will immediately catch the eye. |

| In order to make the structure strong and rigid with the help of cross beams, two grooves are cut in these elements on each side at ⅓ of the height of the beam, on which it is installed on the support beams, as shown in this figure. After they are installed, they are fixed from above to the support boards with self-tapping screws 150 mm long. |

| To make the installation of transverse boards less complicated, you need to accurately measure all the distances and depth of the grooves. If the markup is carried out correctly, the installation will go smoothly. To make the grooves neat and even, cuts are made in the boards to a marked depth, and then the cut piece of wood is selected with a chisel and a hammer. The best option is to make one template beam, fit it exactly, and then cut it out required amount"clones". It is immediately necessary to drill vertical holes for self-tapping screws, which should fall exactly in the center of the selected grooves. |

| After the installation of the cross beams is completed, five crossbeams are installed perpendicular to them and parallel to the supporting boards. They are also fixed on measured and cut grooves - according to the same technology, which was mentioned a little higher. |

| If there are 13 cross beams, then the same number of grooves should be cut. Moreover, the crossbars should be put on with grooves on the crossbars freely, so the grooves are made slightly larger than the thickness of the boards on which they are installed. After that, the assembly of the pergola can be considered complete. |

As you can see, the assembly of such a pergola is quite simple. The main thing is to prepare quality material and be very careful with the details.

Miniature pergola gazebo

This is the most compact version of the pergola, which at the same time will serve as the basis for liana plants, will decorate the site and create a secluded place for privacy lovers.

To make such a mini-pergola gazebo, you will need the following materials:

| The main elements of the design of the gazebo | Necessary materials | Dimensions of parts, mm | Quantity, pcs. |

|---|---|---|---|

| Pillar foundation (if needed) | Asbestos concrete pipes | Ø 200÷250, length 1200÷1500 | 4 |

| Cement, sand, gravel or crushed stone for filling pipes. | Depending on depth. | ||

| Racks (A) | wooden beam | 50×100×1800 | 4 |

| Seat frame (B) | bar | 50×100×1625 | 2 |

| 50×100×460 | 3 | ||

| Bench back (C) | bar | 50×100×1625 | 2 |

| 25×100×275 | 13 | ||

| Cross beams (D) | Board | 50×200×1800 | 2 |

| bar | 50×50×840 | 9 | |

| Seat (E) | Board | 20×100×1625 | 6 |

| Lattice cladding (F) | bar | 50×50×1350 | 4 |

| 50×100×410 | 4 | ||

| Consumables | Nails, screws and screws. |

In order not to repeat ourselves, it must be said right away that for this gazebo, as well as for previous buildings, a foundation is being laid. Since this version of the structure has a very small weight, it is most likely not necessary to make a deep foundation. If the site has a cemented or tiled platform, then this small pergola can be installed on it by inserting the racks into special stands that are fixed to the base. In addition, it is recommended to cement the lower part of the stand so as not to accidentally injure your leg on a sharp metal corner.

Further installation operations are carried out as follows:

| Illustration | Brief description of the operation to be performed |

|---|---|

| The racks on which all other structural elements will be fixed must be prepared by making cuts in their upper part - they will be needed to install the cross beams. |

| The next step, in order to ensure the rigidity of the structure, is to assemble the seat frame and attach it to the uprights. The fastening must be reliable, so it is advisable to use metal corners for it, which are installed on the underside of the frame frame. Installation height is indicated on the assembly diagram. |

| Further, the back of the bench is assembled from the timber and boards, which will strengthen the rear pillars of the structure. This item is recommended to be assembled separately and in ready-made fasten the backrest to the rear pillars of the structure. Since the back will also have a large load, it may also be worth using metal fasteners, which must be installed from the back of the backrest, linking it to the support posts. |

| When the racks are securely fastened at the bottom with the seat and back frames, you can proceed to fastening them at the top. In this model, curved parts are made for the longitudinal beams - a board with a size of 50 × 200 mm is used for them. A curved beam is cut according to a pre-drawn pattern using electric jigsaw. After that, the beams are cleaned and polished with sandpaper of different grain sizes. The finished parts are installed in the cuts, equipped in the upper part of the support posts, and then fixed in them with the help of self-tapping screws. |

| Further, longitudinal cladding boards are screwed onto the frame frame of the seat in three places with self-tapping screws 30 mm long. They are distributed evenly on the frame bars, and between them it is imperative to leave gaps 5 mm wide for good diversion water and ventilation of wood. |

| For the manufacture of side lattice panels, a beam of 50 × 50 mm is taken, from which a frame is made, on which a finished lattice ordered from professionals is fixed. The grate can also be made independently, for example, by spreading the beam with a circular saw into slats 5-7 mm thick. The grille is mounted on a frame made of timber between two wide glazing beads, which will ennoble the grille and make it neat by closing its edges. |

| The next step is to mark the installation step on the curved crossbars, and then fix the perpendicular boards with cuts and self-tapping screws, which are installed on the edge. If desired, the roof can be covered with roofing material. |

| To protect the wood from moisture and transform the appearance of the pergola, it is covered with paint or stain and varnish. The color is chosen depending on the general design of the landscape of the site. |

After getting acquainted with the manufacturing technologies of gazebos of various designs, it is possible to choose the one suitable for your own site, objectively evaluating your capabilities in carpentry. After that, you can safely get to work - the main thing is not to rush and make all the parts and their connections as accurately as possible.

And at the end of the publication - an interesting video in which the master shares his secrets of quick construction garden gazebo.

Video: a master class on the quick construction of a gazebo

A cozy family dinner in the fresh air, tea drinking on the weekend, chatting with friends or just being in nature - all these moments are associated with a gazebo. It is especially pleasing if this element of the exterior is made by hand. Explore design and construction options various kinds pergola and get valuable advice for their construction.

Anyone who has a creative approach and imagination will be able to build a gazebo with their own hands. Initially, decide on the place of construction of the gazebo and prepare the site for work.

This is followed by the definition of the shape of the structure, the choice of materials for its manufacture, the creation of drawings. In relation to this, the foundation is laid, the frame is erected. The final stage is the finishing of the roof of the gazebo.

Choosing a place for a gazebo should be based on its functional features. If the gazebo will perform the function of receiving guests, noisy feasts, then build it near the house. The arrangement of a gazebo in the garden opens up new opportunities for admiring nature and enjoying passive relaxation.

A pleasant appearance opens from the gazebo, we recommend building it near flower beds, ponds, green spaces. Another an important factor creating a quality gazebo is harmony with environment. Finishing, material for building walls - must fit into the landscape on the site.

Do-it-yourself gazebo: photos, drawings:

Simplifies the process of building a gazebo - the presence of a specific action plan and all the necessary tools. If you don't have experience, choose simple shapes buildings - rectangular, square. Decide in advance on the material for finishing the walls in the gazebo, the absence or presence of a wooden floor, the possibility of supplementing the structure with a barbecue.

The technology of building a gazebo with your own hands from wood

Wooden gazebos are the most common. This is due to the ease of processing this material and affordable cost. Besides, wooden structures have the following advantages:

- attractive appearance, harmony with the exterior, naturalness;

- the possibility of combining with glass, metal, brick surfaces;

- long-term operation, with proper care and processing of wood;

- environmental safety of the materials used;

- ease of installation work;

- the ability to create a design of any configuration and shape.

Before the start of construction wooden gazebo consider the following processes:

1. To ensure maximum durability and strength of the structure, prepare a quality foundation for the gazebo and carefully treat the material with an antiseptic composition.

2. Functional Features gazebos determine its size.

3. At the initial stage of work, the construction site is cleared of vegetation and debris and leveled.

4. The design of the gazebo should match the surroundings, use high quality building materials when doing construction work.

5. Create a correct and well-thought-out project, in which the entire action plan for building a gazebo with your own hands is described to the smallest detail.

Before you make a gazebo with your own hands, decide on the type of structure being built:

- closed - has a permanent roof - is operated at any time of the year;

- open - suitable only for summer use, some variants of such arbors are covered with an awning or an arched roof is made of pergolas.

The simplest and most convenient in everyday life is a rectangular version of a wooden gazebo with a gable roof.

Gazebo with your own hands:

After drawing up an action plan, the process of determining Supplies to build a gazebo. In the process of work, prepare materials in the form of:

- sand, cement, gravel - for concrete mortar;

- piles;

- wood;

- bricks;

- reinforcing bars;

- wooden beam;

- metal corners;

- fasteners in the form of self-tapping screws and nails;

- finishing material for roofing: polycarbonate, shingles, slate, corrugated board.

To work with wood, you will need tools in the form of:

- electric planer;

- special saw;

- a set of keys;

- grinding equipment;

- hammer and screwdriver.

Divide the work of building a gazebo into several stages, carefully approach the implementation of each of them.

1. Choose a place to install the gazebo.

It is not recommended to build a structure in the lowlands, since under the influence of moisture that accumulates there, the gazebo will quickly begin to rot and collapse. When the gazebo is directly adjacent to the house, try to make it in the same design as the main building. Make sure that a pleasing view of the exterior opens from the gazebo. In addition, we recommend installing the building in places protected from wind loads, near walls or fences. Provide full access to the gazebo by creating a path to it.

2. Build a foundation for a wooden gazebo.

There are several types of foundation suitable for a gazebo. The choice of one or another option is determined by the total mass of the structure, the characteristics of the soil and individual characteristics site.

The simplest, most convenient to manufacture and reliable is the columnar version. To create such a foundation, follow a series of steps:

- make markings with a rope and a peg;

- clean the soil 5-10 cm from the top layer;

- make recesses of 50 cm;

- lay sand, gravel, concrete on the base;

- lay roofing felt to provide waterproofing;

- build brick pillars that provide a small ventilation gap between the gazebo and the foundation;

- re-install the roofing material.

It is possible to build a shallow strip foundation or installation of piles. In the latter case, work is carried out at maximum speed, it is enough to purchase ready-made screw piles and install them in pre-marked areas. At the same time, it is not necessary to wait for the concrete solution to harden, as in the previous version. Therefore, with a limited time interval, we recommend stopping at the pile version of the foundation.

There are several options for installing the floor - in full contact with the walls or installing the walls on the base of the foundation. We recommend choosing the second option. If necessary, such a design is quite simple to assemble. For the manufacture of the floor, use wood in the form of a bar with a section of 100x100 mm. Pre-treat the wood with a moisture-resistant antiseptic and flame retardants. Boards are installed on logs from a bar.

4. The construction of the frame part is the next stage of work on a wooden gazebo.

On the one hand, the frame of the building must protect the interior from the wind, but on the other hand, it must be open. The construction of blank walls is a meaningless process. Used to build walls edged board fixed on the beams with nails. Initially, load-bearing supports are constructed from timber, and then install boards, the evenness of which is checked by a level.

5. Internal and exterior finish walls in the gazebo.

The easiest option is to decorate the walls with wooden boards. To improve the attractiveness of the gazebo - build window openings in it, wooden railings, use carvings, openwork lining. Additionally, decorate the gazebo with curtains, fresh flowers, textile elements in the form of pillows and seat covers.

6. Installation of a roof in a wooden arbor.

Choose roofing material for the gazebo in relation to the main residential building. There are many options for finishing the roof in the gazebo: slate, tiles, corrugated board, bituminous roofing, polycarbonate, metal.

After construction is completed, install the necessary furniture in the gazebo: table, chairs, sofas, armchairs. If necessary, add a brazier, however, keep in mind that when using a brazier, the wood is pre-treated with flame retardants - compounds that prevent combustion. It is possible to install electrical wiring in the gazebo, install lighting fixtures.

In order for the wooden gazebo to serve you as long as possible, follow the recommendations below for caring for the structure:

- before the start of winter, remove debris from the gazebo, tree leaves;

- for the winter, cover the building with polyethylene film;

- periodically treat the structure with an antiseptic composition;

- all furniture and household items are taken out of the gazebo for the winter.

Arbor do-it-yourself photos and original ideas

A wooden gazebo is a standard option, we suggest that you familiarize yourself with unusual and extraordinary options for constructing gazebos.

1. Arbor from plastic bottles.

An excellent option for saving when creating a gazebo. Bottles are used both for wall cladding and for roofing. Plastic has good performance characteristics, excellent weather resistance. The use of bottles of different colors and their combination help to create real masterpieces, as cheap as possible in cost.

2. Arbor from the trunk of an old tree.

If there are fruit trees that do not bear fruit on the site. Saw them up and build a gazebo. The natural curves of the wood make the gazebo elegant and natural. First, remove the bark from the trees and open them with varnish. For the manufacture of roofing in this case, shingles or reed mats are perfect. Additional protection from the wind will provide walls made of vines.

3. Live gazebo.

This option is the most harmonious with nature. appearance. For the manufacture of gazebos, only shrubs and trees planted in a special way are used. To create a frame, use metallic profile. The disadvantage of such a gazebo is the fact that it functions only from late spring to mid-autumn.

How to build a gazebo with your own hands: a polycarbonate gazebo option

A polycarbonate gazebo has the following advantages:

- lightweight design - the gazebo does not need an expensive foundation, it is possible to build a mobile gazebo, which is transferred from place to place;

- ease self-manufacturing- the material is easy to process, is diverse color solutions, long in operation;

- the possibility of combination with other materials in the form of glass, wood, metal.

Among the advantages of polycarbonate, we note:

- ease of cutting and processing;

- the ability to bend the material at a certain angle;

- ease of drilling;

- resistance to temperature extremes;

- operation in conditions of high humidity;

- Fire safety;

- high mechanical strength;

- excellent light transmittance.

Arbor do-it-yourself drawings and dimensions:

Before starting work, decide on the type of construction and create a drawing. Next, level the area and make a markup. For a gazebo with your own hands, the dimensions are determined taking into account the functional load on the building.

The need to build a foundation and its appearance depends on the weight of the structure, the complexity of its execution and the size of the gazebo.

To fix polycarbonate, create frame structure. There are several options for it:

1. Wood.

Among the advantages, we note: naturalness, affordable cost, ease of processing, excellent appearance. Among the shortcomings, we highlight: the need for constant care, fragility, instability to weather influences.

2. Metal.

Advantages of a metal structure: mechanical strength, reliability, service life. Disadvantages: high cost compared to wood, the need for additional anti-corrosion treatment.

3. Stone frame.

Materials are natural, attractive appearance, long service life. Design flaws: the need to build a powerful foundation, high cost, duration of construction.

When choosing a light gazebo design, it is enough to install the supporting elements, without pouring the foundation. Otherwise, erect a tape, columnar or monolithic foundation. The frame for polycarbonate must be strong, rigid and even. For fixation wooden elements use screws or nails. Metal constructions connected by welding machine or bolts. To create stone walls, stock up on cement mortar. All parts are interconnected in relation to the drawings. This is followed by the process of mounting polycarbonate on the frame structure.

DIY gazebo video:

The gazebo is an essential attribute of modern suburban areas. Where, if not in the gazebo, you can relax, breathe fresh air, admire your garden. Since the gazebo is a light structure, in some way, even airy, the scope for creativity, when constructing a gazebo, opens up limitless. But, everything should be in moderation, as they say - without fanaticism. The design of the gazebo should correspond to the general spirit and style that prevails on suburban area. Of course, a gazebo in the form of a Chinese pagoda is very beautiful. But, then, to match her, she will have to build a rock garden around her so that it is a holistic composition, and the pavilion in the form of a pagoda does not dissonate with the environment.

An important element is the size of the gazebo. And here we must proceed from the principle of proportionality. How smaller garden, the more elegant and lighter the design of the gazebo should be. In some cases, you can use a lightweight collapsible design.

The location of the gazebo also plays a big role. Installing it in the sun, you will not get much pleasure. The optimal location of the gazebo is a place next to the trees, or under the crowns of trees that will inspire coolness. A good option for the location of the gazebo is to install it next to a reservoir, natural or artificial. And it is desirable that the place for the gazebo be chosen in a place where there are no sources of noise.

Arbor classification

Arbors are classified according to different criteria. Pavilions are divided into stationary and portable. Stationary gazebos include gazebos built on a foundation, which makes it difficult to move them from place to place, and built from durable materials. Portable gazebos are lightweight, mostly collapsible structures that are installed in those places where it is necessary in this moment.

Arbors are classified according to the type of material from which they are made. The most commonly used material is wood. Metal is also used in the construction of gazebos. At the same time, metal gazebos are divided into forged and welded.

Also, for the construction of gazebos, stone, both natural and artificial, and concrete are used. These are massive structures that are rarely seen.

Arbors are divided into open and closed. Open gazebos include mushroom gazebos, tent gazebos and pergolas. Pavilions-mushrooms are used by site owners who do not want to clutter up their site with unnecessary structures. Arbors-awnings - are a structure consisting of a table, chairs or benches and covered with an awning from above. Pergolas are special structures designed for growing climbing plants. They have a solid base and construction to withstand wind loads. The forms of pergolas are very different - round, multifaceted, linear, fan-shaped.

Closed gazebos are a kind of terraces. Such arbors are usually glazed, often insulated, they are supplied with heat or use internal heating. In such arbors, winter cold is not terrible.

In addition, gazebos are divided according to the type of roof used. The arbors use spherical roofs, domed, single-pitched and gable, hip (four-pitched), hipped, pseudo-Chinese.

Gazebo with barbecue or barbecue

It would not be an exaggeration to say that all people who live or travel to country plots and summer cottages for recreation are very fond of cooking outdoors. And the main dish, which is especially often prepared in this case, is fried meat. This is a barbecue or steaks of meat or fish cooked on a barbecue. It would seem, what is the difficulty here? Put the brazier in the gazebo and talk with friends while the barbecue is being prepared. But such a decision is fundamentally wrong. It will be inconvenient to talk, and it will be inconvenient to follow the barbecue. Most arbors are built on the basis of healthy minimalism, and are designed to accommodate a table, chairs or benches in it. AND extra bed they usually don't. In addition, the smoke from burning wood or coal will remain in the gazebo, and no one will get any pleasure from it.

To avoid these inconveniences, it is necessary at the design stage of the gazebo to provide for the placement of a barbecue and hood in it. It would seem that everything is obvious, but such thoughts come when the gazebo has already been built. How to get out of this situation? One of the options is to build an additional extension to the gazebo, but in such a way that the design of the gazebo does not deteriorate, and place a barbecue with a hood in this extension. Thus, we, as it were, divide the gazebo into two zones - a recreation area and working area. In this case, fire safety is also increased, and the possibility of burns of guests from a nearby barbecue is excluded.

If you want to build a stationary brick brazier, then when building a gazebo, it is necessary to provide for the construction of a foundation for the brazier, since the floor, in this situation, will no longer be a reliable support. In addition, you will need a place to store firewood or charcoal, for fireplace accessories, and shelves for other accessories.

Arbors made of polycarbonate

IN Lately, appeared on the market new material, gaining more and more popularity among owners of cottages and suburban areas. This new material is called cellular polycarbonate. It has outstanding physical, chemical and mechanical characteristics, which make it popular. Polycarbonate is a very durable material (10 times higher than plexiglass), it passes well sunlight while providing protection against ultraviolet radiation, resistant to aggressive chemicals, provides excellent sound and heat insulation, without changing its properties endures extreme temperatures: from -50 to +125 degrees Celsius. And, which is very important for summer residents, it is perfectly processed without breaking.

Below are a few examples of the use of polycarbonate in suburban and suburban areas.

Building a gazebo with your own hands (1 option)

Next, we will talk about the construction of a wooden gazebo, measuring 3 by 3 meters. After determining the location of the gazebo and marking the territory, the foundation of the future gazebo is being built. You can learn more about the types of foundation from the article "Types of foundations for the construction of a building"

In this case, a columnar foundation of bricks was used. All columns are displayed in one level. Iron bars with a diameter of 10 mm are mounted in four corner posts. Their height is approximately 200 mm.

The finished foundation looks like this.

Bars measuring 100x100 mm make the base of the gazebo. At the junctions, the bars are fastened "half a tree". Previously, holes are drilled in the bars for attachment to iron pins.

Do not forget about the waterproofing between the foundation and the beams. As insulation, a piece of roofing material is quite suitable.

Then poles are made from 100x100 mm bars. Their height is 2.3 m. They are processed with an electric planer. Before installation, a cut is made in the middle of the post for the future diagonal strapping. The size of the cut was 40 width x 80 height x through the post diagonally. (for use in strapping 40 mm boards 100 mm wide)

Holes are drilled in the lower ends of the pillars for fitting onto rods. After that, the pillars are aligned vertically, and fixed with temporary struts. Additionally, they can be fixed with screws to the base bars.

The intersection of the boards can be reinforced with 40x40 mm bars.

At the edges of the bundle, a part of the board is selected with a size of 20 mm in height and 100 mm from the edge of the board.

Then the diagonal strapping is inserted into the cuts and fixed with nails into the ends of the pillars.

After that, the outer binding of the pillars is done.

The roof of the gazebo is supposed to be made four-pitched. A bar 80 cm long (roof height) is cut out of a 100x100 mm beam, in which a cut is made, into which the first two rafters will be inserted.

After that, the post with rafters is installed so that the post rests on the middle of the diagonal ligament, and the rafters lie on the vertical posts. The departure of the rafters outside the gazebo is done at a distance of 40-50 cm. The rafters are fixed with 200 mm nails or screws. After that, two other diagonal rafters are fixed. They are attached to the post.

Then the rafters are fixed, which lie on the outer trim of the pillars. Fasten with nails and screws.

For the manufacture of the entrance, two columns 90 cm high are prepared from a bar 100x100 mm, in which a hole is drilled in the lower end.

Pieces of reinforcement are driven into the lower beam, previously sharpened on which the bars are mounted.

Then short railings of the gazebo located on the side of the entrance to it are attached to the bars with screws.

After that, the roof lathing is done.

For the pillars of the gazebo, stationary struts are made from a bar of 40x70 mm. They are fixed on the screws, and the temporary struts are removed.

From the entrance side, the struts are made crosswise to strengthen the short railings and low posts. At the intersection, the struts are connected "half-tree".

To enhance the bearing capacity of the gazebo, additional posts are installed between the lower beam and the railing, and between the railing and rafters. The entrance is also fortified. The result is this.

Then, under the railing and on the lower beam, 30x40 blocks are nailed, to which the lining will be attached.

The lining is nailed to the bars, both outside and inside.

After that, the flooring of the roofing material is carried out. Yes, do not forget to treat the surface with water-repellent impregnation. This will prevent the formation of mold and rotting of the tree. As a roofing material, soft tiles or any other roofing material can be offered.

You can learn more about variations of roofing materials from the section "Roofing materials".

In the upper part of the gazebo (from the railing to the top trim of the pillars), a decorative crate is made. In addition to a purely decorative function, it enhances the design of the gazebo.

Also on this lattice it will be possible to start climbing plants. Then a pediment is installed, which is attached to the rafters.

All surfaces must be treated with a stain or other water-repellent compound. This can be done both during the construction of the gazebo, and after the completion of its construction. And now the gazebo is ready.

Do-it-yourself gazebo with entrances from the end, with benches and a table (option 2)

This type of conversation is the most common. It is often offered for sale in various construction markets. This is an option when you have a canopy over your head, benches are attached to the walls, there is a salt in the middle, and there are two entrances (exits) on the ends.

Assemble the frame first. Initially, you can install spacer technological screeds, later they can be removed ...

And a crate for a profiled sheet

fasten the profiled sheet to the crate

Naturally on both sides

Here is such a view. Now the technological ties can be removed.

We are starting to make benches.

Now the table

Everything must be sanded from skidding and bumps ... It will not be easy without automated tools.

That's general form the resulting gazebo. It remains to cover the paintwork, giving color and protective properties.

Now the next option for making a gazebo.

Arbor from ready-made modules with your own hands (option 3)

An example of this gazebo is modular design. In fact, the floor and walls are made in the form of panels that are assembled. Rafters are mounted on them, flexible tiles are laid. At the end, the porch is made. More on all this below.

First of all, this gazebo needs modules - shields. They are a platform with windows at a certain height (3 pieces) and one module with an entrance door.

The edges of the modules are attached to the beam, which will be installed vertically. There is also a modular, assembled floor.

In fact, the floor is the base of the gazebo installed on a columnar foundation. Let's start with the foundation. We install brick posts or pour concrete.

After we fall asleep them with a sand pillow and let them settle.

Next, install the floor and the bars at its corners. We install the floor through an insulating material so that it does not draw water from the stone. Also, the boards can be pre-treated with a corrosive compound. Between the vertical bars going from the floor we put walls - shields.

Now you need to install the rafters on the roof.

We stuff boards on the rafters. In our case, the gazebo will be covered soft tiles so the boards are mounted close to each other.

Excessively protruding rafters are cut off after mounting the roof boards

Now it's time for the tiles. We lay it out and fasten it on four sides.

You can also make a small staircase, for the convenience of entering the height of the gazebo floor

We process all visible parts with stain and varnish. Our gazebo for giving from the modules is ready.

Do-it-yourself hexagonal hexon gazebo (option 4)

And another version of the gazebo will be considered by us. This time the gazebo is a hexagon at the base. As always, it all starts with the foundation. In our case, it is completely "no". It is preferable to make at least a columnar foundation at each corner of the gazebo floor.

We collect the hexagon at the base. The bar is best fastened with a tongue-and-groove connection.

We put a floorboard on the floor.

We install vertical bars at the corners of the floor

We connect them from above with rafters and ceilings.

We make a crate for a profiled sheet, which will cover the roof of the gazebo

We mount the profiled sheet and the ridge on the folds of the roof

Let's take the railing. We mount jumpers from below and from above, we nail railing boards on them.

We pick up trash. If necessary, we make a small porch of brick or boards.

A hexagonal gazebo for a summer residence, where you can spend time pleasantly and carelessly, is ready!

Photos of gazebos for an example of construction

If you have decided to make an open gazebo with a swing and a hearth, then we have such an option "

There are so many options for building gazebos in the country that it is not difficult to choose the design that is ideal for your backyard and will meet the requirements for it. The following describes how to make a gazebo-tent, fungus and rotunda with your own hands. In addition, you will be able to learn how to build beautiful gazebos of other designs.

If you do not want to install a solid stationary gazebo on the site, you can limit yourself to small things: build a light tent.

To build a gazebo-tent with your own hands, you need to place four concrete disks or slabs in the corners of the vending site, which will serve as the foundation of the structure. In each of them, install a metal rod or tube made of aluminum or durable plastic, which are connected at the top together with a clamp or wire. You form arch-supports for a canopy.

As you can see in the photo, for a gazebo-tent in the country, you can use dense colored fabric, oilcloth or thick film as a cover:

First fasten the material in the center - put on a new clamp over the connection of the arcs or wind the wire or twine, but through the roof fabric. Then pull the awning and tie it to the supports, and so that the fabric does not slip through the pipes, tighten the clamps in place of the ties. When making such a gazebo with your own hands, a circle of two or three racks from the ground to the awning can be pulled mosquito net(as an option - a large-mesh net through which climbing plants are put), leaving a place for entry.

Under this gazebo-tent in the country, you can place a rocking chair, a table, light plastic chairs, a folding bed for daytime sleep- everything you need for outdoor recreation. This design will successfully stand the entire holiday season, and it is necessary to disassemble it only with the onset of cold weather, and then only by removing the fabric awning.

How to build a beautiful mushroom gazebo for a summer cottage with your own hands (with photos and videos)

To protect yourself from the sun and rain, you can make a cottage-fungus gazebo on the site with your own hands: the support of this small open building consists of two parts: the lower one - a metal pipe 0150 mm and 1.5 m long, and the upper one - wooden rack 2 m long.

Before you build such a gazebo in the country, you need to install a pipe. To do this, a hole 50 cm deep is dug in the intended place, a pipe is installed, covered with rubble, tamped and concreted. While the concrete is curing, you can make the fungus itself.

The lower end of the wooden post is hewn so that it fits snugly into the pipe to a depth of 50 cm. Then the roof frame is assembled at the upper end of the post. Having measured 70 cm from its top, bars 15 x 15 cm and 5 cm thick are nailed on four sides. Laths 80 x 15 cm of the same thickness are attached to each of them from below, thus obtaining a cruciform lower part of the frame. In the manufacture of a slope, four similar slats are used. They are marked in place and washed down from the ends "on the mustache". At the joints, scarves are nailed to increase strength.

Look at the photo - such a do-it-yourself gazebo can be sheathed with any suitable material (plywood, oilcloth, plastic):

The finished rack with a mushroom roof is inserted into the pipe and a bench is installed around it. The iron posts of a wooden bench can also be concreted into the ground. If desired, a small table is arranged around the central pillar of such a beautiful gazebo built by one's own hands. To do this, corners are welded to the pole, on which a composite tabletop of two halves is placed with a cutout for the pole in the center.

This video shows how to build a fungus gazebo in your backyard:

How easy it is to make a summerhouse-rotunda with your own hands

It is very easy to make a cylindrical gazebo-rotunda: as practice shows, for it it is best to use pieces of 0.8 mm reinforcing wire, the lower ends of which must be vertically fixed in the bricks of the annular base, and the upper ones, bent towards the center and connected together, should form a kind of dome . The strength of the structure is given by horizontal weaves from the same reinforcement. The entrance to the gazebo is through a vaulted opening.

To make such a simple gazebo with your own hands, you will need about 50 pcs. red solid brick and 310 running meters reinforcing wire with a diameter of 8 mm.

Before you build a gazebo-rotunda, you need to choose a suitable site and break the base. In the center of the future gazebo, a peg is driven into the ground and, having tied a twine or twine to it, two concentric circles with radii of 1.75 m and 1.9 m are marked on the ground. Then they are removed from the resulting annular ditch upper layer soil to a depth of 15-20 cm, instead of which a layer of sand 10-15 cm thick is poured, watering it abundantly and ramming it.

Laying bricks on the prepared base at small intervals and pouring and compacting sand in the gaps between them, they get the foundation of the foundation of the future gazebo. The bricks must lie horizontally with their top surfaces flush with the platform.

Look at the photo - to build such a gazebo with your own hands, a hole of 8-10 mm is drilled in the center of each brick to install reinforcing bars:

It is better to do this with an electric drill with a carbide drill. To prevent the bricks from splitting, first drill holes with a thinner drill (03-4 mm), and then drill them to the required diameter.

When installing rods for a do-it-yourself gazebo, do not forget to skip 4 bricks - this place will be the entrance to the gazebo. If you want to make the passage wider or narrower than 1 m, skip more or less bricks, assuming that each is 250 mm long.

Having closed up on cement mortar in the holes, pieces of reinforcing wire about 4 m long each, they are bent to the center of the gazebo at a height of 2-2.2 m. The shape of the gazebo dome will depend on the bending radius. The ends of the reinforcement brought together in the center are welded to the central ring 0200 mm.

Then, when making a gazebo for a summer residence, they begin to form a central harness. Horizontal rows are spaced 275 mm apart. The intersections of the reinforcement bars are seized by welding, having previously fixed them with clamps.

The finished garden gazebo, made by hand, is coated with a metal primer, such as PF, and painted in a discreet color. In conclusion, climbing and climbing plants should be planted around the gazebo. By the end of the first summer season, they will wrap around the frame and make it almost invisible and windproof, creating the impression of a weightless green dome. Even during the most intense summer heat, this gazebo will be cool and fresh, and the simple design of the gazebo, hidden by beautiful flowers and foliage, will delight guests.

The technology of construction and installation of a welded metal gazebo in the country (with photo)

Continuing the theme of metal buildings, learn how to build a gazebo with your own hands, the entire frame of which is welded from steel corners. Such a building may not look rich, but it is quite capable of decorating a modest plot of six acres and will allow you to fully relax after working in the garden.

For the corner posts you will need a 75 x 75 mm corner, and for the rest of the frame elements - a 50 x 50 mm corner. Welded guardrail metal gazebo finished with eurolining, the tabletop is made of grooved boards.

Pay attention to the photo - the highlight of the folded gazebo is the original roof:

For the manufacture of the frame, you first need to mark the position of the corner posts, two pillars of the doorway and the places for installing the table and benches.

For the stability of a welded gazebo made by oneself, all racks should be concreted. To do this, use a mechanical drill with a diameter of 25 cm to make holes 75 cm deep. For concreting, use a mixture of cement, sand and crushed stone with a fraction of 20-40 mm in a ratio of 1: 2: 1.5.

Observing the construction technology of such a gazebo, when concreting, it is important to control the verticality of the racks, for which it is very convenient to use a level with magnets that allow you to securely fix the tool on the rack from the steel corner, freeing your hands.

The pillars of the doorway of a welded gazebo for a summer residence differ from the corner ones - they are thinner. You can, of course, make a doorway from a thick corner or immediately concrete different corners, but it is better in the places where the opening will be located, to monolithize segments of the corner 75 x 75 mm so that they protrude above the supports by about 50 mm. To these protruding ends, the opening racks themselves are then welded from a corner of 50 x 50 mm. Such an entrance to the gazebo will look more elegant.

When the concrete at the base of the corner posts grabs, cut the corners with a grinder or a hacksaw, which will become elements of the upper, middle and lower trims. Weld the steel corners of the upper trim along the perimeter of the gazebo by welding, trying to ensure the squareness of the resulting frame. After that, you need to weld the corners of the middle and bottom strapping. Perpendicular to the sides of the upper trim, weld the corners 50 x 50 mm crosswise, and in the center of the resulting crosshair - vertical stand, to the top of which 4 diagonal rafters are already attached. According to the installation technology of such an arbor, the corners must be installed in such a way that the corner shelf is facing up.

For guard metal surfaces from corrosion, they are covered in two layers of oil paint (MA-115) of black color, allowing the first layer to dry well.

Roof manufacturing. To fasten the cladding elements and roof parts made of dense fiberboard to the metal elements of the gazebo frame, first attach wooden blocks section 40 × 40 mm. For fastening, use screws 03.5 x 35 mm, which are screwed in from the inside through the holes in the metal corners.

Triangular blanks of roof slopes are marked out according to a cardboard template. Using a saw with a straight small tooth, file blanks from dense fiberboard. Attach the cut blanks to the bars screwed with screws to the metal inclined ribs (corners) of the roof.

As can be seen in the photo, the roof of the gazebo in the country house, erected by hand from a welded structure, is made of bituminous tiles:

The basis for the flexible tiles on the roof of the gazebo is uncoated roofing material, glued to the fiberboard using bituminous mastic. Tiles of flexible tiles are also glued on bituminous mastic, and in places of overlap they are nailed with small galvanized nails with a diameter of 0.5 x 20 mm with round caps. Tiles are glued, starting from the lower edge of the slope, overlapping the glued lower one with the top row.

During the construction of the gazebo in the country, the bars of the batten of the fence are placed on the corners of the frame from the outside, attracting them to the corner with screws from the inside. For sheathing, it is best to use lining, pre-painted with two layers of paint. Profiled boards are nailed to the crate with galvanized nails 01.0 x 20 mm with small caps. Along the perimeter of the fence, handrails made of planed bars with a section of 50 x 100 mm are nailed.

Handrails and railings should be coated with durable furniture colorless varnish in three layers.

In the upper part of the fence, you can install sliding green trellises: cut them to the size of the openings and screw them to the rails stuffed over the handrails with screws.

When preparing the base, you first need to select a layer of soil about 5 cm thick inside the gazebo, and then level the surface in a horizontal plane. Lay gravel on top with a layer of 3 cm and carefully tamp. After that, pour coarse river sand with a layer of 3 cm. Instead of sand, it is better to use the so-called muchka (crushed industrial slag) with the addition of M400 cement (about 10% of the volume).

When building a gazebo in the country for paving the floor and making a blind area, paving slabs 300 x 300 mm can be used. Such a coating will go well with a tiled roof if the tiles are used in different colors and laid in a checkerboard pattern. For laying tiles, use rubber mallet and building level 500 mm long.

After laying paving slabs, it is necessary to pour plenty of water, and after drying, remove the remnants of flour or sand.

From the outside, around the perimeter of the gazebo, tiles are laid with a slope outward - they serve as a blind area. The water flowing down from them during the rain falls into a nearby gutter and is diverted from the gazebo.

To build a welded gazebo in the country, follow the photos below:

A simple summer gazebo made of fabric for a summer residence with your own hands (with photo)

As mentioned earlier, many materials are suitable for creating gazebos. But there are often problems with their delivery to the summer cottage, and construction works, as a rule, do not end quickly.

Few people know that there is an easy, fast and simple way to build structures such as gazebos, showers, verandas, toilets. And as building materials you only need pieces of any fabric, epoxy and four metal pipes or wooden poles for supports. The technology of building a gazebo from a fabric for a summer residence is extremely simple.

Install four pillars (metal pipes, logs, etc.) in the chosen place at the corners of the future building.