In order for high temperatures to be present in the bathhouse for the longest possible time, and the costs of maintaining it to be minimal, you need to think about high-quality insulation of the building. Thanks to the thermal insulation layer, the interior of the bathhouse will quickly heat up and cool down slowly, and the service life of the building will significantly increase. We suggest you figure out how to properly insulate the walls in a bathhouse from the inside and outside.

Materials for bath insulation

When deciding how to insulate the walls in a bathhouse, you will definitely encounter the problem of choosing insulation. When purchasing a heat insulator, you need to take it into account specifications and standard sizes, environmental friendliness and fire safety.

Types of thermal insulation materials:

- Mineral (basalt) wool. The most popular option for an insulator that promotes best preservation heat in the bath. The new generation of mineral wool insulation is produced using not formaldehyde, but chemically neutral acrylic that does not emit toxic substances when heated.

- Peat blocks filled with sawdust and straw. They are characterized by bacterial static, non-flammability, and hygroscopicity.

- Foam glass. Environmentally friendly insulation that perfectly retains its operational properties over time, but heavy in weight and expensive.

- Cork mats. They do not absorb moisture, do not deform, and retain heat well.

- Polyurethane foam boards. With aluminum coating on both sides. Used for insulation of Finnish baths.

- Expanded polystyrene, foam plastic. It is used as an insulator for insulating bathhouse walls from the outside, but not from the inside, because its destruction occurs at +60 degrees, and carcinogens are released.

- Natural insulation. Felt, wool, reeds, sawdust, moss, flax, straw, hemp - materials that have been used for insulation of Russian baths from time immemorial. It is not recommended to use it without special treatment to avoid rotting and damage by rodents.

How to perform insulation

Thermal insulation of bathhouse walls is carried out comprehensively, always insulating the building from the inside, and in some cases, both from the outside and from the inside. Log and timber baths As a rule, they do not insulate the outside, but only the steam room and washing room from the inside. Baths made of bricks and foam blocks - materials with high thermal conductivity - must be insulated from the outside to ensure the required temperature conditions inside the building. To insulate the bathhouse externally, first install the sheathing, secure the thermal insulation, wind and moisture-proof membrane, and at the final stage - the outer cladding.

Stages of insulation of bathhouse walls from the inside

- Cleaning, sealing and filling of cracks in the base base. The walls of a bathhouse made of logs or timber are caulked with jute or linen insulation, minor defects in brick and foam concrete planes are corrected with sealants.

- Treatment with antiseptics, preventing the spread of pathogenic microorganisms, and fire retardants, reducing the likelihood of fire.

- Installation of wooden sheathing for installation of heat insulator. The width of the sheathing step is selected based on the width of the insulation (1 cm less), and the thickness of the bars - based on its thickness.

- Installation of insulation. By cutting a roll of mineral wool into strips of the required width or using slabs of a certain standard size, you can ideally install the material in the wooden frame of the bathhouse - in the spacer between the guides of the sheathing.

- Installation of vapor barrier. The optimal material for quickly insulating a bathhouse with your own hands is a rolled or slab mineral wool insulator with a foil layer. It’s like a “2 in 1” - a material that can significantly reduce installation time and acts as an effective heat protection and vapor barrier. If the insulation does not have a metallized coating, then it is recommended to cover it with a vapor barrier film with an overlap of at least 5 cm, for example, Ondutis R Termo - a vapor barrier with heat-saving properties that can withstand temperatures up to +120 degrees and returns 80% of the heat back into the room. After installation, all joints of the insulator are glued with foil (aluminum) tape.

- Finishing. The inside of the bathhouse is traditionally sheathed with wooden clapboard, for the installation of which an additional 2-3 cm thick batten is attached to the sheathing fixed for installing the insulation. It will serve as the basis for fastening the clapboard and will create the necessary ventilation gap between the front sheathing and the vapor barrier. This way, the condensate that forms can flow down unhindered, leaving the lining dry.

The stages of internal insulation of a bathhouse built of wood, brick or foam blocks are almost identical, only the thickness of the heat insulator varies. It is advisable to install a double layer of insulation in the steam room to retain heat for a longer time. Some professionals do not recommend insulating log, timber and frame baths at all or using a thin insulator - wood already retains heat very well, in their opinion.

When insulating the walls of a brick bath, galvanized bricks are used instead of wooden blocks. steel profile. When installing a heat insulator to walls made of foam blocks, you need to think about redistributing the load - optimally if it falls not on the walls, but on the floor. For this purpose, a vertical sheathing is used, fixed to the ceiling and floor, secured to the walls with galvanized clamps.

Conclusion

When deciding how to insulate the walls of a bathhouse, you need to carefully approach the purchase of thermal insulation material. For external wall insulation baths will do inexpensive polystyrene foam, mineral wool or expanded polystyrene, facing bricks or hollow ceramic blocks. For internal insulation of a bathhouse, you can use both natural, time-tested materials and modern ones. We must also not forget about reliable vapor barrier, condensate removal and heat conservation of the bath.

The main function of the Russian bath is to strengthen human health. To achieve this goal and in no way harm your body while visiting the bathhouse, you must properly insulate the bathhouse. If you follow all the rules for insulating this type of room, the heat in the bathhouse is maintained long time, which allows you to save significantly cash spent on its heating.

The process of insulating walls in a bathhouse

The process of insulating walls in a bathhouse In most cases, insulation must be done indoors. This allows you to quickly heat the bath and also quickly cool it if necessary. The bathhouse has the following properties:

- Relatively low air temperature 50-60 degrees;

- High humidity. Sometimes it can reach 100%.

Step-by-step internal insulation of a bathhouse

Step-by-step internal insulation of a bathhouse

In order for these indicators to remain normal, you should not only properly insulate the bathhouse, but also use for this purpose proven over the years and proven performance.

Existing types of insulation for baths

Existing types of insulation for baths All of them, without exception, must meet the following safety requirements:

- Do not violate, but only maintain a healthy atmosphere in the bathhouse.

- Resistance to air temperature changes.

- No harmful impurities released into the atmosphere.

- Without smell.

- Fire resistance.

All these indicators should be taken into account in the process of general insulation of a bathhouse, especially when choosing insulation for a steam room.

Insulation scheme for a steam room in a bathhouse

Insulation scheme for a steam room in a bathhouse Nowadays, there are many completely different products on the market. different types insulation materials. Among them, the most popular and popular among buyers are the following types.

Mineral wool

Mineral wool is a natural material with a fibrous structure. It is obtained by processing mineral stone, some of its rocks, for example, basalt rock. Vata has a number useful properties. These include:

Mineral wool sheets for bath insulation

Mineral wool sheets for bath insulation Mineral wool comes in different densities and hardnesses. In specialized stores it can be purchased in the form of soft rolls, semi-rigid mats or hard slabs. It all depends on what purposes it is intended for. In other words, it will be used to insulate the bathhouse from the inside, or vice versa from the outside.

Glass wool

Glass wool in its technical indicators lags significantly behind mineral wool. It is made using glass, or rather, its waste remaining during its production.

The process of finishing a bath room with glass wool

The process of finishing a bath room with glass wool Glass is mixed with soda, sand and dolomite. The result is high-quality insulation.

It is recommended to insulate a bathhouse with glass wool only from the outside, as it does not tolerate high temperatures well. And over time, it begins to smell quite unpleasant. Basically, glass wool is used to insulate the attic and roof of the bathhouse.

Jute felt

It is also called the interventional type of insulation. Felt made from jute fiber is a natural material of natural origin. It is produced from the fibers of the jute plant.

This is what a roll of jute felt looks like

This is what a roll of jute felt looks like Jute fiber is mainly used to make ropes. It is also used to produce fabric - burlap. Everywhere they use it to insulate a bathhouse, namely its walls.

Jute is able to retain heat well indoors and also removes excess moisture from it. The jute fiber itself is quite fragile and rigid. That's why, to strengthen it thermal insulation properties flax fibers are added to it. The most famous brands of this insulation are flax jute, felt, and flax wool.

All of them are collected in tape reels. It is characterized by such properties as resistance to subsidence and drying out, and the felt practically does not rot.

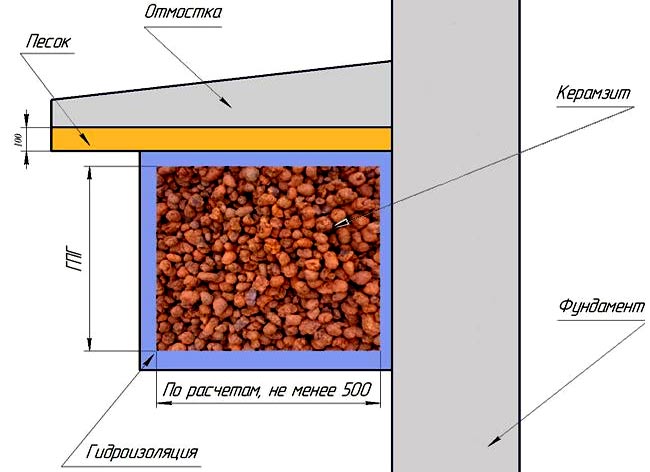

Expanded clay

This is a material with thermal insulation properties. It is mainly used for insulating floors and in bathhouses. Expanded clay looks like small balls. Their production is associated with a process such as rapid firing of clay.

An example of insulating floors in a bathhouse with expanded clay

An example of insulating floors in a bathhouse with expanded clay

Thermal insulation of a chimney with expanded clay

Thermal insulation of a chimney with expanded clay

Used as one of the types of backfill. The thermal insulation effect is achieved when the backfill layer reaches a height of at least 25 centimeters.

Styrofoam

It is used for insulating external walls. The material is covered all over, then it is plastered or covered with cladding.

An example of finishing a bath with foam plastic

An example of finishing a bath with foam plastic

Polystyrene foam cannot be used to insulate walls inside the building itself. It releases phenol into the atmosphere. Polystyrene foam is unable to withstand elevated temperatures and does not have sufficient fire resistance.

Watch the video for a review of bath insulation.

An example of fastening insulation in a frame bath

An example of fastening insulation in a frame bath

They are first covered with a protective film and only then the insulation - basalt wool - is fixed.

The process of installing a vapor barrier in a frame bath

The process of installing a vapor barrier in a frame bath In the steam compartment, a vapor barrier film with foil is additionally used.

Insulation of a log bathhouse

A bathhouse made of wood practically does not need insulation. The only places that are subject to this process are inter-crown joints. For thermal insulation, jute fiber is used with the addition of flax elements.

Detailed diagram insulation of a log bathhouse

Detailed diagram insulation of a log bathhouse

The steam room of the bathhouse is also subject to additional insulation. Mineral wool is suitable as insulation for it. Foil is used to vapor barrier walls.

Insulation of a block bath

The insulation of a block-type bathhouse is similar to the process of insulation of a brick bathhouse. To begin with, the walls of the bathhouse are insulated from the outside. This will allow you to maintain the optimal temperature in the room. The walls from the inside are traditionally lined with aspen clapboard. It is the most suitable option because it has low thermal conductivity.

Diagram and names of elements for insulation block bath

Diagram and names of elements for insulation block bath

In addition to this insulation, the walls in the steam room are covered with a so-called warm layer. It consists of a layer of mineral wool surrounded on both sides by foil or vapor barrier film.

The process of installing a wooden frame on blocks

The process of installing a wooden frame on blocks

Having thus completed all the necessary steps to insulate a block bath, you can achieve relative ease in warming up the room to certain temperature levels and maintaining it for as long as required.

Proper insulation of individual bath blocks

Any bathhouse needs good thermal protection. At the same time, each individual block of the bathhouse must be insulated in its own way. Not only modern types of expensive insulation are suitable for this. Since the time of our grandfathers, simple and affordable materials have been known. So how and with what can you insulate a bathhouse yourself?

Names of elements and principle of insulation of a bath room

Names of elements and principle of insulation of a bath room Insulation of the bathhouse foundation

For its insulation, only those types of insulation are suitable that have the following properties:

- Resistance to high humidity.

- Biological resistance to various types of damage.

- Ability to withstand temperature changes.

Polystyrene foam has these properties. With its help they do it immediately after it hardens. In this case, sheets of cellular foam are fixed along the outside of the base of the bath.

Bathhouse foundation insulation scheme

Bathhouse foundation insulation scheme

The thickness of these layers should be 5 cm. It is best to use 2 layers of styrofoam, arranged in a checkerboard pattern.

As additional insulation, the foundation is covered with warm plaster.

Read also

Construction of a sewer system for a bathhouse

Bathroom floor insulation

Traditionally, the floor in the bathhouse is wooden flooring. There are two types of flooring:

- Leaking floor. This is the name given to a cold floor, where there are small gaps between the boards. Through them, water flows from the bathhouse to the street.

- Non-leaking floor. This is the so-called solid floor. It differs from the previous gender in a way. This floor is made with a slight slope in one direction. A special water collector is made in the basement of the bathhouse.

The process of insulating the floor in a bathhouse

The process of insulating the floor in a bathhouse

Only floors that do not leak can be insulated in a bathhouse. At the same time, two types of insulation are suitable for such purposes: expanded clay and basalt wool. They fill all the cracks between two floorings: rough and finishing. It should not be forgotten that both of these materials need protection from moisture. It is performed both from the outside and from the inside. If the bathhouse has a concrete floor, then polystyrene foam or mineral wool in the form of hard mats are used to insulate it.

The process of laying foil material on the floor

The process of laying foil material on the floor

In the steam room, the concrete floor is not insulated at all. To protect from the cold, you just need to put wooden gratings on top of it. IN washing department For a concrete floor, a so-called underfloor heating system is created.

Insulation of bath walls

In the process of insulating the walls of a bathhouse, it is especially worth paying attention to their costs. To enhance the protection of walls from moisture, it is not a film specially designed for this that is used, but insulation with a reflection effect or foil.

Wall insulation scheme in a bathhouse

Wall insulation scheme in a bathhouse

When installing such insulation, be sure to leave a small gap between it and the finishing of the bathhouse.

An example of laying mineral wool on the walls in a bathhouse

An example of laying mineral wool on the walls in a bathhouse

When installing upholstery, it is advisable to use lathing. It is fixed on top of the mirror side of the insulation. The mirror film is fixed on the walls in a vertical position. In this case, avoid stretching the strips.

The process of attaching foil to the walls in a bathhouse

The process of attaching foil to the walls in a bathhouse Since this material is quite thin, the foil on the wall is made of two layers. All joints between strips are taped with special tape.

In stone baths, basalt wool is used for additional wall insulation. It is protected on both sides by hydro-vapor barriers.

Insulation of the ceiling in the bathhouse

The ceiling, like no other part of the bathhouse, needs reliable thermal protection. Heated sauna air comes out most of all through him. The bathhouse ceiling can be insulated in two ways. These include:

Previously, sawdust with leaves was used to properly insulate the ceiling of a bathhouse. Dry sand at least 5 cm thick was poured on top. The ceilings were covered with a layer of liquid clay. This method of ceiling insulation is quite popular and is still used today.

Bathhouse roof insulation

The roof of the bathhouse is insulated using a standard insulation scheme. Exactly according to the same scheme. The insulation is selected based on how the bathhouse attic will be used in the future.

Scheme for installing insulation on the roof of a bathhouse

Scheme for installing insulation on the roof of a bathhouse

If it is planned, then in this case the roof will be covered with mineral wool.

If the attic is planned to be used only for household needs, then mineral wool can be replaced with glass wool.

This will help to significantly save money allocated for the purchase of insulation.

An example of foil thermal insulation on a ceiling

An example of foil thermal insulation on a ceiling

- Stage 1: ceiling insulation

- Stage 2: wall insulation

- Stage 3: floor insulation

Often the problem of thermal insulation of apartments and houses is not paid attention to, but for baths it is of particular importance. After all, if you do not insulate the steam room, then the heat will not stay in it for a long time. Therefore, it is so important to insulate the bathhouse from the inside, paying special attention to the steam room. After all, this is where you have to spend more time.

- bars;

- self-tapping screws;

- nails;

- screwdriver;

- saw;

- foil;

- Styrofoam;

- glass wool;

- waterproofing material;

- polyethylene film;

- blank paper;

- masking tape;

- anti-corrosion composition;

- building level;

- façade panels;

Stage 1: ceiling insulation

Stage 2: wall insulation

Scheme of wall insulation in a bathhouse.

Stage 3: floor insulation

Scheme of floor insulation in a bathhouse.

Scheme of insulating a bathhouse from the outside.

Insulating a steam room with your own hands: step by step instructions(video and photo)

Insulating a steam room with your own hands is quite simple. You just need to read the step-by-step instructions and prepare everything you need for work.

Insulating a steam room from the inside step-by-step instructions

Insulating the steam room allows you to solve the problem of heat loss, otherwise the effect of visiting the bathhouse will be reduced to zero. The thermal insulation of a given room can be called high-quality if insulation work has been carried out on the ceiling, floor and walls.

The temperature in the steam room must be maintained at a high temperature. At the same time, heat loss must be minimized, and insulating the steam room from the inside will help achieve the required level of thermal protection. When constructing a bathhouse building, this room should be equipped according to all the rules.

The better the thermal protection of the steam room, the less fuel will be required to heat it during operation, and the longer the steam will be able to remain in it, which has a beneficial effect on the human body. Regardless of the material used to build the bathhouse, the insulation process certainly consists of thermal insulation of the ceiling, flooring and walls.

Materials used in arranging steam rooms

To insulate the steam room internally, in former times people used exclusively environmentally friendly materials. They not only retained heat well and were easy to use, but at the same time had a number of disadvantages, including susceptibility to rotting.

Modern materials meet many of the requirements for them:

- successfully withstand high temperatures;

- tolerate high air humidity well;

- do not emit substances harmful to human health;

- look aesthetically pleasing.

In order to thermally insulate the steam room from the inside, the following building materials are used:

- wooden slats(for arranging the sheathing);

- mineral wool or glass wool;

- polyethylene film;

- penoizol (can be replaced with aluminum foil);

- expanded polystyrene;

- perlite;

- concrete solution;

- reinforcing mesh.

Before insulating a steam room in a bathhouse from the inside, you should prepare the following tools:

For the internal lining of the steam room, wooden slats, boards or lining are most often chosen, which depends on the personal preferences of the owner of the building. It is wood that meets the operational requirements for such premises.

Low-density deciduous wood is ideal - alder, maple, linden and aspen. As for coniferous trees, at high temperatures their wood will begin to release resin.

Insulation of steam room walls from the inside

Properly performed insulation of the walls of a steam room from the inside is a structure of several layers: steam, hydro- and heat insulating. Particular attention should be paid to the arrangement of the first of them, since it must protect the remaining layers from the influence of hot steam. If it penetrates into the insulation, this material may become wet and lose all its properties.

Most often, a vapor barrier is installed using aluminum foil or special insulators that are coated with a foil layer, for example, it can be penoizol (the material is shown in the photo). At the same time, experts do not recommend using such well-known vapor barriers as roofing felt, polyethylene, glassine when covering a steam room, since at high temperatures they begin to release toxins that are dangerous to human health.

In turn, the foil prevents the insulation from getting wet and at the same time provides the effect of a thermos, as a result of which heat will be retained indoors for a long time.

Waterproofing is essential to protect the thermal insulation material from moisture. The fact is that poorly laid waterproofing material in conditions of high humidity, namely the air in the steam room, can trigger the onset of the rotting process. The appearance of mold and mildew on walls can cause irreparable harm to both the structure and human health.

For waterproofing, foil or special film materials are most often used. The joints of the panels must be sealed with tape to prevent steam and condensation from penetrating into the insulation. All these materials for arranging waterproofing are mounted using construction stapler.

The next layer when creating thermal protection for the steam room will be the installation of thermal insulation, which is made using materials that have the property of retaining heat. These include mineral wool and glass wool.

The first of the above-mentioned insulation materials is an environmentally friendly natural product. But mineral wool is afraid of moisture and loses its properties when wet. When using mineral wool it is necessary for everyone possible ways to prevent the penetration of moist air, so this insulation is carefully wrapped with foil and films.

Glass wool differs from mineral wool in that it does not get wet and therefore can be used to insulate a steam room from the inside. When the steam room is insulated from the inside - step-by-step instruction suggests that work should begin by fixing wooden sheathing to the walls, to which insulation is then installed.

Thermal protection of the floor and ceiling from the inside

Basically, heat loss in the steam room occurs due to insufficient thermal insulation of the ceiling, since warm air flows always rise upward. For this reason, the ceiling should be insulated not only from the room side, but also from the attic side.

Thermal insulation of the ceiling on the steam room side is carried out in the same way as it is done with walls. First of all, the wooden sheathing is fixed. Then a thermal insulation material is attached to it, preferably glass wool. It is covered with a vapor barrier on top, and an outer finishing layer is installed on it - most often lining.

As for the ceiling on the attic side, it can additionally be insulated with straw, clay, sawdust or other materials. Near the chimney pipe for protection fire safety special mastics are used.

Currently, various floor coverings are installed in steam rooms. You can insulate the floor, for example, with expanded polystyrene. This material is characterized by high mechanical strength, fairly low thermal conductivity, and in addition, once in a humid environment, it does not change its qualities.

When using it to insulate a steam room from the inside, the step-by-step work looks like this:

- A waterproofing layer is placed on a prepared, level base using a special film, on which polystyrene foam boards are laid tightly one to the other.

- To give the structure greater strength in order to increase its service life, a reinforcing mesh is mounted on the polystyrene foam and concrete mortar is poured. When performing work, you must not forget about arranging a slight slope to ensure water drainage.

- After the concrete has completely hardened, which usually takes about a month, you can begin laying the finishing floor surface. A good option is to lay ceramic tiles.

You can also insulate the steam room floor using a natural material such as perlite, which is sand expanded by a special method. To create insulation, take 2 parts perlite and part water, mix and combine with cement. Mix the whole mass thoroughly.

The base of the steam room floor is poured concrete screed, on top of which an insulating mixture is placed and allowed to dry for a week. Then the screed is made again and the work is completed with a finishing floor covering made of finishing material.

Sometimes in a steam room, wooden gratings are placed on a high-quality concreted, durable and reliable floor, which should be periodically dried during operation to avoid rotting and rapid deterioration.

How to insulate a steam room?

- What will be required to carry out the work?

- Stage 1: ceiling insulation

- Stage 2: wall insulation

- Stage 3: floor insulation

- Stage 4: insulation in the steam bath from the outside

Often the problem of thermal insulation of apartments and houses is not paid attention to, but for baths it is of particular importance. After all, if you do not insulate the steam room, then the heat will not stay in it for a long time. That’s why it’s so important to insulate the bathhouse from the inside. paying special attention to the steam room. After all, this is where you have to spend more time.

At the same time, it is necessary to insulate the steam room with high quality, performing all the work in stages. Below are step-by-step instructions. She will help you in this difficult, but so important matter.

What will be required to carry out the work?

The first step is to prepare all the materials and tools that will be needed to insulate the steam room. Here is their list:

- rolled thermal insulation material;

- bars;

- self-tapping screws;

- nails;

- screwdriver;

- saw;

- foil;

- Styrofoam;

- glass wool;

- waterproofing material;

- polyethylene film;

- blank paper;

- masking tape;

- wood material for cladding (linden, aspen);

- anti-corrosion composition;

- building level;

- facade panels;

- water-repellent varnish for wood.

Stage 1: ceiling insulation

Scheme of ceiling insulation in the steam room.

First of all, thermal insulation in the steam room should be done for the ceiling. First you will need to cover it with rolled paper; it is important that its joints overlap (from 10 to 15 cm). After this, it needs to be strengthened, otherwise deformation will occur during further work. To do this, you need to take small blocks (size 5x5 cm) and nail them to a roll of thermal insulation material.

It is important here to create a monolithic coating so that seams with cracks do not form, otherwise the tightness of the waterproofing will be compromised.

As a result, steam will penetrate into the rolled thermal insulation material, which will lead to its deformation and deterioration of its performance characteristics.

Scheme of the ceiling in the steam room.

Now you need to secure the foil with additional blocks. This will prevent it from peeling off, and the finished sheathing will also allow you to quickly lay down the finishing material. Wood should act as it. The use of non-ecological materials here is simply unacceptable. After all, you will inhale the harmful substances that they emit when taking water treatments in the bath. As a result, instead of improving your health, you will, on the contrary, worsen it. It’s great if you use linden or aspen for cladding the ceiling. These materials emit special resins that heal the body and make the atmosphere in the bathhouse better, as a pleasant smell spreads.

You can attach the finishing material to nails, making sure to pre-treat them with an anti-corrosion compound. The wood itself must be coated with a water-repellent varnish. It is better to do this before it is fixed to the ceiling. After all, then you will be able to process it from all sides at once, which will extend its service life.

Using boards you need to create an even surface. To prevent misalignment, be sure to use a building level. In addition, for finishing, choose only those boards that have the same thickness, otherwise differences in height in the finished coating cannot be avoided.

Stage 2: wall insulation

Scheme of wall insulation in a bathhouse.

Do not assume that only the ceiling needs to be insulated. The walls also need additional finishing using insulating materials. Therefore, having completed work with the ceiling, you will need to move on to them. It is also necessary to start insulating walls by laying out rolled material. It must then be nailed down with a wooden frame, which is immediately lined with foil. But here it is necessary to take it with a thickness of 65-70 mm. After all, much more heat escapes through the walls than through the ceiling. Therefore, the use of thinner material here is not permissible. Lay it out overlapping, and cover all joints several times with masking tape. Then it will be possible to make the surface of the walls as airtight as possible. As a result, the steam room will be as warm as possible.

After this, a wooden frame is installed on the foil fixed to the surface of the walls. And the finishing material is already installed on it. It is not necessary to use boards here. you can choose lining for the walls. By the way, you can also decorate the ceiling with it, but then the insulation in the steam bath will cost a pretty penny, but if you have allocated a significant budget for this, then feel free to opt for this material. The aesthetic and performance properties will not disappoint you. The wall decoration will turn out great and will delight you every time you take water treatments.

Stage 3: floor insulation

Scheme of floor insulation in a bathhouse.

Now you can insulate the floor in the steam room. Here the work is carried out according to a slightly different scheme. The first thing you need to do is waterproofing. It is necessary to prevent mold, mildew and rot from appearing inside the floor. This layer will protect the floor from condensation. To create it, you will need to use plastic film. It is laid out over the entire surface of the floor. If there are seams, make large joints and seal them with masking tape.

Next you will need to create another layer on top of the film. It must be laid out from clean, thick paper. It is necessary to ensure that no harmful substances are released from the base of the floor. In addition, such a layer will minimize the loss of hot air. It will definitely need to be secured to a wooden frame of small width. And you need to lay out mineral wool slabs on the frame and fix them with self-tapping screws.

Then the following material is laid out on the floor surface: polystyrene foam. It needs to be attached on top of the cotton wool using small nails. After which you will need to cover it with foil and put plastic wrap on it again. So many layers need to be created in order to minimize heat leakage through the floor, which occurs through it in large quantities. As a result, the insulation will be of very high quality.

And the last thing you need to do is create another frame on the floor surface. It should be thicker than the previous one. It is necessary for subsequent finishing. After all, you will need to lay boards on the floor surface. Pre-treat them with water-repellent varnish.

Stage 4: insulation in the steam bath from the outside

If your bathhouse is wooden, then you must insulate it from the outside. After all, a sealed floor, walls and ceiling in this case will not be enough. Therefore, here you need to create a crate outside the bathhouse; mineral wool slabs should be laid on it. They need to be fixed with screws or nails. After which it is lined with plastic film. Next, the façade panels are laid on it. All of them must be varnished. This will protect them from adverse environmental factors.

Insulation in a steam bath consists of these stages. As it becomes clear, complex work needs to be carried out here. It is not enough to insulate only the surface of the walls and floor; you also need to not forget about the ceiling and external cladding. This is the only way to do quality work. The result will not disappoint you. And since all the instructions are presented in an accessible form and are step-by-step, using it, you can do everything yourself.

The main thing is to prepare everything in advance necessary tools and materials. We wish you good luck in insulating your steam room!

How to insulate a steam room in a bathhouse with your own hands

Preface. In Rus', since ancient times, bathhouses were built from log cabins; today, along with this traditional material, timber, foam block, expanded clay and other modern materials are used. Thermal insulation of the steam room will solve the problem quick loss the heat and heat from the steam room will not leave so quickly.

How to properly insulate a steam room wooden bath? Thermal insulation of the dressing room and steam room will be of high quality if the work touches all three planes of the steam room - floor, walls and ceiling. Most of the heat escapes through the ceiling of the bathhouse, but other surfaces should not be ignored, including the door to the bathhouse. Let's look at how to properly insulate a steam room in a bathhouse.

Is it necessary to insulate the steam room in a bathhouse?

Photo. Insulating a steam room from the inside with your own hands

Despite the low thermal conductivity of modern and traditional materials, any steam room needs high-quality insulation. Especially when it comes to internal thermal insulation structures in the steam room - walls, floor and ceiling. Insulating a steam room is a very important task; when working, you should strictly follow the manufacturers’ instructions and take into account other nuances.

For example, not all heat and steam insulating materials can be used when finishing the floor and ceiling in a bathhouse. Many materials do not withstand moisture, and if used in this room roofing felt or glassine, then a visit to the steam room can be ruined unpleasant odors from these materials. The choice of thermal insulation is made depending on the material from which the bathhouse was built.

How to insulate a steam room in a bathhouse from the inside

The most common materials for the construction of bathhouse walls are logs, timber, foam concrete, aerated concrete or expanded clay concrete. Compared to natural wood, the thermal conductivity of the blocks is higher, which means that thermal insulation of the steam room is simply necessary. But, before considering the technology for carrying out the work, you should figure out how and how to insulate a steam room in a timber bathhouse with your own hands.

If basalt wool was chosen as thermal insulation, then high-quality mineral wool vapor barrier should be performed, since this material absorbs moisture. The most balanced solution for finishing wet rooms is penoplex or foil penofol. Extruded polystyrene foam is often used for self-insulation strip foundation and blind area of a private house.

For owners of bathhouses made of blocks, there is no question of whether or not to thermally insulate the room from the inside. It is important to learn how to insulate a steam room in a block bathhouse yourself. Thermal insulation technology is divided into three main stages: arrangement and insulation of the walls, floor, and ceiling of the steam room of a brick bath. All work can be done on your own and inexpensively.

How to insulate the walls of a steam room with your own hands

Photo. Thermal insulation of walls in a log steam room

Thermal insulation of log walls in a steam room from the inside is a layered “pie” of vapor barrier, thermal insulation and waterproofing layer. The vapor barrier film on the side of the warm room protects the mineral wool from moisture and the effects of steam; in addition, it additionally creates the effect of a “thermos” in the steam room and is a natural heat reflector.

Roll waterproofing prevents moisture from entering walls made of logs or timber, protects the structure from condensation and the formation of fungus, and prevents the process of rotting of the structure. To do this, use polyethylene film, foamed polyethylene or foil. The waterproofing film is laid between the thermal insulation layer and the walls in the steam room made of blocks or wood.

The insulation layer itself is placed between guides fixed to the wall. When installing the frame, please note that the distance between the guides should be 1 cm less than the width of the mineral wool slab so that the basalt slab fits tightly into the frame. If you use slab insulation, then all cracks should be thoroughly foamed.

How to insulate a steam room ceiling with your own hands

Photo. Thermal insulation of the ceiling in the steam room

If many people neglect the thermal insulation of walls, then insulating the ceiling in a steam room with your own hands is simply necessary in any bathhouse. Since this part of any building is the most vulnerable in terms of heat loss. Through the ceiling of the steam room, hot air leaves the room in a short time.

To insulate the ceiling in the steam room, inexpensive base materials were previously used - sawdust mixed with ordinary earth or expanded clay. The ceiling boards above the steam room were covered with loose thermal insulation, thereby significantly reducing heat loss in the room. These “old-fashioned” methods, even with the arrival of new materials, until today have not lost their relevance.

The ideal option for finishing the ceiling in a steam room is thermal insulation of this structure from the outside, i.e. from the attic side. To do this, use glass wool or basalt insulation. Where the chimney pipe comes out of the ceiling, you should use non-flammable insulation - expanded clay or Rocklight mineral wool. Let's consider further how to insulate the floor in a steam room.

How to insulate a steam room floor with your own hands

Photo. Insulating the floor in a steam room with penoplex

Let's consider a more common option for thermal insulation of the floor in a steam room - using polystyrene foam or extruded polystyrene foam. Penoplex extrusion answers everything necessary requirements requirements for thermal insulation of wet rooms. This material does not absorb moisture and is not afraid of rodents, but the insulation should only be laid on a flat base.

Most often, the floor in a bathhouse is insulated under a screed. To do this, a waterproofing film is laid on the ground to protect against groundwater, then slab insulation. Gaps and cracks between the plates should be sealed with foam. At the end, a reinforcing mesh is laid and a concrete screed is made. To waterproof concrete, penetrating composition Penetron or liquid glass should be used.

To finish the floor in the steam room, floor tiles or porcelain stoneware are used. You can also lay a wooden floor on joists, which will be more pleasant and warm for your feet.

How to insulate a steam room

Without a good steam room, a bathhouse loses its meaning of existence. During the construction of baths, special attention is paid to this room. The main task of the steam room is to store hot air and steam for a long time, to ensure the quality of bath procedures at the highest level. A main job builders - insulate the steam room in the bathhouse in such a way as to eliminate prolonged heating and rapid cooling, and increase the concentration of steam.

Poorly performed thermal insulation work and the use of low-quality materials will inevitably lead to the appearance of dampness, mold, and rotting of wooden structures. This applies to all surfaces of the steam room: floor, walls, ceiling. It is very important to carefully and step-by-step carry out work on insulating the steam room from the inside; step-by-step instructions will help you correctly navigate the sequence of actions and the choice of materials.

Choice of insulation

A steam room is a specific room, so the choice of thermal insulation materials for walls, ceiling and floor should be approached responsibly. The insulation for the steam room must be moisture resistant, not afraid of significant temperatures, and not emit toxic substances. Mineral wool, or more precisely its variety - stone or basalt wool, most closely fits these definitions. It is also produced in the form of slabs of various thicknesses and dimensions. The material is easily cut with a regular construction knife, so stone wool slabs are very easy to adjust to the required dimensions. To furnish the floor and ceiling on the outside, loose insulation materials are used - expanded clay or expanded perlite.

Foil material is most suitable for steam and waterproofing for steam rooms. It is produced on a foam base or on kraft paper. You can use any of them, but in the case of insulating a steam room from the inside, preference is usually given to the second option.

The procedure for performing insulation procedures

The process of insulating the steam room in a bathhouse proceeds from top to bottom. That is, work starts from the ceiling, then the walls and, lastly, the floor. It would not be superfluous to remind you that before starting insulation work, wooden surfaces should be cleaned of dust and signs of fungal manifestations. It is necessary to treat the wood with antiseptic preparations and a fire retardant, since it is possible to insulate a steam room in a bathhouse from the inside efficiently and effectively only with a well-prepared base.

Ceiling insulation

It is most convenient to insulate the ceiling from the attic side. Ideally, do this on both sides, because the ceiling is one of the most vulnerable parts of any building, especially a bathhouse. It is through this structure that the largest share of heat loss from the inside occurs. So, from above:

- a layer of rolled vapor barrier is attached to the rough ceiling, tightly closing all joints and making an overlap on the pediment and rafter elements;

- pour a layer of expanded clay or foamed perlite and level it;

- in places where the thermal insulation comes into contact with the chimney, they are treated with fire-retardant mastics.

Insulation of a steam room in a wooden bath from the inside on the ceiling occurs as follows. If the ceiling structure below has smooth surface, then a frame is built on it. If there are ribs, there is no such need. The first layer of the thermal insulation cake is a vapor barrier membrane, which is attached to the base, observing the configuration of the ribbed surface. Then stone wool slabs are laid as tightly as possible between the beams and covered with another layer of vapor barrier. The next stage of insulating the steam room, its upper part, is the installation of a protective layer of foil material. The joints between individual sheets are sealed with aluminum foil tape. Particular attention must be paid to the junctions between the ceiling and the walls in order to prevent the slightest possibility of the appearance of “cold bridges”. If necessary, use polyurethane foam.

Baths are built not only from wood; there are options for brick buildings. In such buildings the process of execution thermal insulation works looks a little different. Insulation of the steam room brick bath begins at the stage of constructing the roof structure. Supporting ceiling beams, which are to be embedded in brick walls, are wrapped in two to three layers of glassine or roofing material before laying. The nests for them are made slightly wider than the beams themselves, and the free space is filled with polyurethane foam or mortar. From the outside, the recesses are covered with masonry. Next, the ceiling structure is installed, and insulation is performed in the same way as in a log house.

Thermal insulation of walls

Insulation of the wall surfaces of a brick bath begins with the application of a waterproofing layer to them. Most often, roll materials or mastics that do not contain bitumen are used. Because the specific smell of this material, when heated, can penetrate the room and spoil the positive impression of visiting the steam room. Further, the process of producing thermal insulation work for walls made of brick and wood is the same and is carried out in the following order:

- Vertical bars are placed on the walls in increments equal to the width of the stone wool slabs;

- using a construction stapler, attach a vapor barrier membrane, carefully wrapping it around each beam;

- between the bars, heat-insulating material is tightly laid in one or two layers, depending on the thickness of the slabs; stone wool is a little springy, so it holds well on its own and does not require additional fastening;

- The top vapor barrier layer is made of aluminum foil on kraft paper; you can use foil material on a foam base, but the first option works more reliably in humid conditions.

The foil is secured end-to-end, and the seams are covered with a special adhesive-based protective tape. All work must be carried out carefully and responsibly, but special care is required when sealing corners and places where walls meet the ceiling surface.

Floor insulation

Making warm floors in the steam room is no less important than properly insulating the walls and ceiling. You can use two options: using slab materials or bulk materials. However, in both cases, you need to start with leveling the surface and a rough preparation device. And here, too, there can be two versions: with and without drain. By and large, water is not used in the steam room, so there is no need to install a drain hole there. But some developers do this. Then, when arranging the floor pie, starting from the preparatory layer, slopes are made towards the drain. Otherwise, the floor must be strictly horizontal. Now about the floor structure itself:

- Insulation with polystyrene foam boards. After rough preparation, a layer of waterproofing is laid with a slight overlap on the walls. Then the insulation boards are laid in one or two rows, depending on the thickness. The next step is laying the reinforcing mesh and then screeding it with cement-sand mortar.

- For insulation bulk materials expanded clay or perlite is used. First, waterproofing must be done. Then pour a layer of dry insulation required thickness, level it using the plaster rule according to the level. The covering layer is made with a concrete mixture or mortar.

The clean floor in the sauna is made of rough ceramic tiles and porcelain stoneware. Traditional wood flooring is often used. The decking board behaves well. In addition, its use is useful in terms of safety, since the board has a corrugated surface and does not slip.

Wall and ceiling cladding in the steam room

For cladding walls and ceilings in a steam room, they are usually used. wooden lining. Each owner chooses and arranges the design of the steam room of the bathhouse according to his own taste. However, there are general rules that must be followed. First of all, this is the type of wood from which the lining is made. Linden, aspen, and larch are considered the most suitable. It is undesirable to use breeds containing a large number of resin At high temperatures they emit fumes with a heavy odor. The next requirement is that the lining must not have knots, cracks or other defects. That is, high-quality material is best suited for lining a steam room.

The principle of covering walls and ceilings is traditional. A sheathing is made using aluminum foil with the beams positioned for the planned layout of the lining. Then the planks are attached to the frame, connecting them with tongue-and-groove locks.

Insulating a steam room from the inside - step-by-step instructions

Before insulating the steam room, the owner of the bathhouse must select the correct thermal insulation material, focusing on the following recommendations:

First, the insulator must demonstrate high stopping power. The heat transfer coefficient should not rise above 0.2 W/(m K). And this is only for flooring. And for insulating walls and ceilings, it is better to use a material with a coefficient of 0.2 W/(m K).

Secondly, the insulator should not react to moisture. Especially the flooring material. For walls and ceilings, we can use a membrane or reflector that cuts off moisture, but in the case of the floor, this material will not work.

Thirdly, the open (floor) insulator must have high mechanical strength. There are no special requirements for walls and attic floors. Here the characteristics of the material can be improved through external finishing.

Fourthly, insulating a steam room requires constant contact of the material with an area of high temperatures. Some amateurs manage to heat the room up to 100-120 degrees Celsius, and 75-80 °C is considered a normal temperature. Therefore, the insulation should not melt or catch fire even after a long, many-hour stay in this temperature range.

Fifthly, the material must be absolutely neutral to the human body. Selection harmful substances and provoking allergic reactions is excluded in principle. People go to the bathhouse for health, not for new illnesses.

Eventually, the best option Insulation for the field should be considered granulated expanded clay. It is not afraid of mechanical stress or moisture. It is better to use regular or foil-clad mineral (basalt) wool on the walls and ceiling. It will withstand heat, and a layer of finishing will protect it from moisture and possible mechanical stress.

Polystyrene foam, expanded polystyrene, foil polyethylene are not suitable for insulating a steam room - they cannot withstand heating even up to 70 degrees Celsius.

Well, now that we have selected the materials, you can begin to directly insulate the steam room from the inside, having first studied the step-by-step instructions for the floor, ceiling and walls.

How to insulate a floor - layer by layer overview

To do this, we will have to form a multilayer structure in the direction from the ground, consisting of waterproofing, thermal insulation and finishing. The first layer is waterproofing. It is made in the form of a plastic film, which is laid on the prepared soil. Moreover, the preparation consists of adding a layer of sand, at least 15 centimeters thick.

The second layer is thermal insulation. It is formed on the basis of expanded clay bedding. The thickness of this layer is usually equal to double the thickness of the walls and ranges from 30 to 40 centimeters. Moreover, upon completion of the formation of the bedding layer, we must reach the level of the first crown of the bathhouse frame.

Expanded clay is perfect for thermal insulation of the steam room floor

Next, a reinforcing mesh with 20-centimeter cells is laid on the expanded clay and the screed is poured using sand-cement mortar with filler. Optimal thickness screeds - from 5 to 8 centimeters. At the same time, along the perimeter of the floor, at the level of the future baseboard, it is necessary to fill a waterproofing skirt made of foil, which protects the logs from contact with concrete.

For finishing For a heat-resistant floor, tiles or boards laid on a lath are used.

Insulating the ceiling - step-by-step instructions

To insulate the ceiling in the steam room, you need a completely different heat insulator - foil-clad mineral wool. It can withstand heating up to 700 degrees Celsius and can easily withstand the usual temperature in this steam room zone, which does not rise above 160-180 °C.

The finishing process itself begins with covering the ceiling with an antiseptic primer, which protects the boards from fungus and mold. The second step is to lay sheathing boards on the ceiling, the depth of which should be equal to the thickness of the insulation (usually 10 centimeters). The pitch of laying the boards is equal to the width of a standard strip of mineral wool.

The ceiling is insulated with foiled mineral wool

The third step is laying insulation. After completing the assembly of the sheathing, the space between the boards is filled with mineral wool, laid with foil outward (towards the floor). And all joints are carefully taped with foil tape. After completion of the work, there should be no gaps left on the ceiling.

The final step is installation on top of the sheathing finishing board(lining) or plywood panels. Moreover, in this case, it is necessary to read the description of the specification for the lining - options made of pine and spruce and other resinous trees are not suitable in this case. The ideal lining for a bathhouse is made from hard deciduous trees.

How to insulate walls in a steam room - an overview of the process

Installing vertical thermal insulation on the walls of a bathhouse does not require the use of expensive foil-coated mineral wool. In this case, it is enough to take ordinary mineral wool and aluminum foil, which will serve as a good vapor barrier and shield from high temperatures.

The installation process itself is as follows:

- We saturate the walls with an antiseptic - it will protect the log house from rot and fungus.

- We fill the walls with boards 3-4 centimeters thick and 2-3 cm wider than the depth of the insulation. The spacing of the boards should match the width of the mineral wool roll. At the end, all boards must be soaked with an antiseptic.

- We lay mineral wool on dry logs (the antiseptic must dry), filling the spaces between the boards.

- We stuff aluminum foil over the sheathing, rolling it out in horizontal stripes from bottom to top. In this case, the upper strip should overlap the lower one (2-3 centimeters will be enough). It’s better to use staples (from a stapler) as fasteners. Moreover, it is better to seal the joints with foil tape.

- We stuff 2 centimeter thick planks onto the boards, pre-impregnated with an antiseptic. This will create a counter-lattice. And at the end, on top of these planks, we install hardwood paneling.

Such a scheme allows you to collect very effective thermal insulation, protected from mechanical influences by clapboard finishing. Therefore, almost all steam rooms are finished according to this scheme.

Insulating a steam room from the inside step-by-step video instructions

Insulating a steam room from the inside step-by-step video instructions Insulating a steam room allows you to solve the problem of heat loss, otherwise the effect of visiting the bathhouse will be reduced to zero. Thermal insulation

Insulating a steam room from the inside yourself

The bathhouse helps us relax not only with our bodies, but also with our souls.

Therefore, it is important that the finishing materials not only fulfill their direct function, but also delight in an attractive appearance.

A few general rules

The first step before the next treatment is preparing the work surfaces.

It is necessary to inspect the base to see if there is any fungus and mold on it.

There should also be no foreign inclusions or protrusions.

To get rid of fungus, it is enough to use a regular antiseptic composition.

Without it, insulating the steam room from the inside will remain ineffective.

It is important to pay attention to the safety of materials.

The main requirement in this case is the ability to withstand high temperatures. Materials should not absorb moisture and must have reliable protection against mold.

And remain durable. Aluminum foil and basalt are not bad, modern solutions. The technology itself plays no less a role than the materials.

How to make insulation

During the work we will get a kind of “sandwich”. It usually consists of several layers.

- Waterproofing. Prevents the appearance of fungal and mold formations. And prevents the activation of decay processes. This layer also protects the walls from the appearance of condensation on them. It forms when a surface is exposed to hot steam. Polyethylene film or foil are considered the best waterproofing materials. This is also required for insulating a steam room from the inside in a wooden bathhouse.

- Thermal insulation. Plain, clean paper is first laid on the base. The insulating layer comes only after this. The paper base makes it so that even minimal amount harmful substances. The paper ensures that the minimum amount of hot air escapes. After this, a wooden frame with the same width as the insulating material itself is attached on top. Synthetic board or mineral wool often make excellent insulation materials.

- To protect thermal insulation from the effects of steam, a vapor barrier is needed. It also reflects thermal radiation. And it creates a kind of “thermos” effect. This layer is made of foil, with a thickness of up to 65 microns. Installation is carried out to a wooden sheathing. What are small nails or a stapler used for? The main thing is to carefully cover all edges and joints with foil. Then the steam will definitely not penetrate inside the insulation.

- Internal lining. For which all surfaces are covered with clapboard. The frame is mounted on top of the heat-insulating layer. The lining itself, which is made from different breeds tree. The most important characteristic in this case is the minimum density.

What materials to choose

The question is not only about choosing between materials of artificial and natural origin. There are several other factors to consider.

This applies to purpose and appearance, cost. Materials that solve this issue can be classified into one of the following groups depending on their properties.

- Wall blocks and slabs.

- Matte and lamellar, fibrous varieties.

- Backfills with different densities

Several groups are also distinguished according to their chemical composition:

- Which have a plastic base. This includes polystyrene foam and polystyrene foam.

- Technoblocks and technovets. This is a group of technical insulation materials.

- Inorganic compounds include glass and mineral wool, basalt fiber.

- Organic. These include wood concrete and fibrolite, aqua wool.

Each variety has both advantages and disadvantages. For example, for insulating steam rooms from the inside, plastic insulation materials are not very suitable.

This is due to the fact that such a base does not resist open fire. But they can be used to insulate other rooms included in the bathhouse.

In turn, organic bases benefit from environmental safety. Their cost always remains affordable. But, if you do not use special processing compounds, the material remains flammable.

Inorganic varieties are considered more versatile and practical. This is why mineral wool has become such a popular solution.

Internal insulation will be more effective with materials such as:

- Aluminum foil

- Polyethylene materials

- Glassine base

- Ruberoid types

Vapor barrier with glassine and roofing felt will not give the desired result. After all, these materials, when exposed to high temperatures, emit chemically active and harmful substances.

But glassine is generally used to insulate baths. But best of all, it has proven itself in conjunction with materials such as lining, aluminum foil, mineral wool and log house.

There are several schemes by which insulation is carried out. But one of them has become the most widespread. For example, when using lining with fiber insulation.

- It all starts with creating a frame on the working wall surface. We take timber battens, horizontal and vertical, and fix them on the wall. The timber should be thicker than the insulation, but only by 20-30 millimeters. This reserve is necessary to predict possible shifts.

- After this, the wall is sheathed using mineral wool.

- A layer of vapor barrier is laid on the insulation. The main thing is to overlap the materials. For places with joints and their sealing, thin slats are used. A distance of approximately 3 centimeters should remain between the mineral wool and the vapor barrier.

- The lining is pressed onto the surface of the vertical sheathing. The width of the latter is 40-50 mm. There is still a distance remaining, which will be a kind of gap for the ventilation system.

Such work has proven its effectiveness. But they require certain costs, both in time and in effort.

There are now materials on the market that greatly simplify the entire process. Moreover, they combine the functions of waterproofing and vapor barrier.

One such option is foil foam. This is a fire-resistant insulation; there are no problems with its installation. As you can see, insulating a steam room from the inside is not a very complicated technology.

The scheme described above is well suited for installing timber buildings. Panel and frame structures have their own requirements for this process. There are several lightweight materials that will become indispensable assistants when working with panel walls:

Treatment of the heat insulator with lime milk acts as an additional requirement. In the future, you will need to dry the base properly. Due to this, fire resistance increases, rotting will no longer threaten the material.

If the walls are used in difficult conditions from a climate point of view, then the walls can be covered with fiberboard, or their equivalent - reed slabs. In warm regions, the use of gypsum, cement and particle board compounds will be relevant.

Work order for ceilings

Ceilings suffer the most from exposure to temperatures that are often 160 degrees. The insulation process itself and its features depend on the design of the ceiling itself.

The work will look like this if there is an attic or ceiling.

- We coat the ceiling boards with clay. Its layer should have a thickness of about 20 mm.

- Clay is needed to effectively retain moisture.

- Wooden chips are poured into the cracks that form between the boards.

- Other materials can also be used for thermal insulation. The main thing is that their thickness is at least 200 mm.

The insulation scheme for rooms where there is no attic looks somewhat different. First, a vapor barrier material is laid there. Sheathing and insulation layer come next, followed by ceiling boards and beams.

Depending on the materials used and design features, the order of work will always vary.

Places where insulation and pipes are connected to each other. Between them it is necessary to make an indent of approximately 200 millimeters so as not to violate fire safety requirements. To do this from rafter legs a special box is constructed.

It will be the part that separates one part of the structure from another.

The main thing when insulating a bathhouse is to ensure that there are no places through which warm air could leave the room. It is also necessary to do everything possible to prevent the formation of condensation.

About floor insulation

You can use two solutions to insulate the floor in a steam room.

Polystyrene has an important advantage in the form of a cellular structure. Thanks to this, moisture will never penetrate inside the material. Thermal insulation properties are retained high level, even if the surface experiences severe mechanical stress.

Insulating the steam room from the inside

But this material is most often used in baths that are built of brick.

He demands additional protection, because the brick itself easily conducts moisture inside.

Expanded polystyrene is a material that meets all safety requirements.

But the surface requires preliminary preparation before using such a material.

The main requirements are strength and evenness. You can't do without thorough drying.

A layer of waterproofing is laid on top of the material prepared in advance. Then, on top, the polystyrene foam boards themselves are installed.

Here it is important to ensure that there are no places left without treatment. Gaps and cracks can cause the formation of so-called cold bridges, so they should also be absent.

Decorative coatings are also laid on top, but only after the base has completely dried. Ceramic tiles are one of the best solutions today.

But it is also possible to create a collapsible wooden floor. It fits perfectly into the interior of the bathhouse. And walking on such a surface is very pleasant. With a removable structure, you can dry the boards without any problems, which extends the overall service life.

About ventilation in the bathhouse

It is impossible not to consider this issue when touching on the topic of insulation.

Particularly stringent requirements are imposed on this part of the system in the bathhouse. Ventilation should not just provide air flow into the room. It is important that it does not let the cold in, but retains heat.

To solve this problem, it is necessary to create special supply and exhaust channels. An inlet opening is located near the stove, slightly above floor level.

Concerning exhaust duct, then it should be on the opposite side, in the upper part of the room. Special valves provide air flow regulation. One more condition must be met for the system to work properly - that the supply opening be half the size of the exhaust opening.

The operation is regulated by valves. If you manage them correctly, you can achieve the desired results. If you open only one valve, only pleasant aromas will remain in the room and the air will be fresh. Intensive forced ventilation is organized by opening two valves at once.

About floor waterproofing

The base and its materials determine which insulation method is used in a particular case. Each method should be considered separately.

Concrete floor insulation

This is the simplest and most affordable waterproofing solution for those who have a steam room. It is suitable for washrooms where the floor is completely filled with concrete. The order of work will be as follows.

- First, the floor surface is leveled until there are no deviations at all. Even the slightest dimples and tubercles are unacceptable.

- After this they proceed to applying bitumen mastic. You have to wait until it dries.

- Polyethylene film and roofing felt are laid on top of this layer.

- The base of the floor is ready, you can proceed to laying ceramic tiles.

There is a second method. Its implementation is more complicated. But the result justifies all the costs; such waterproofing will pleasantly surprise you with its high quality. There are several steps you need to take.

- A plywood sheet is fixed to the surface of the subfloor.

- Hydrosol is laid on top of plywood. This is a material whose edges extend behind the wall.

- All joints in the waterproofing layer are reinforced with aluminum tape.

- Places of seams and joints that remain untreated are sealed with a regular construction hairdryer.

- Next comes laying the reinforced mesh and laying the concrete mortar.

- The last stage includes decorative cladding.

To prevent all walls from getting dirty, the lining is covered with tape. You also need to look at the age of the log house for the bathhouse. Buildings usually last for at least two years before complete shrinkage. Otherwise, the floor surface will be deformed.

Insulating a wooden floor

This insulation method is very similar to what we wrote about earlier. It features the simplest step-by-step instructions.

- A layer of mineral wool mat with a minimum thickness of 15 cm is fixed under the joists.

- Roofing felt or euroroofing felt is fixed on top of the first layer.

- Wooden structures require mandatory antiseptic treatment. This will eliminate the risk of rotting. And it will protect materials from spontaneous combustion and eating by insects.

- The subfloor must be laid on top of the antiseptic layer. After that, everything is sheathed using clapboard.

- Only the decorative cladding will remain.

Door insulation with mineral wool

Insulating a bathhouse is a process that takes place somewhat differently than in other rooms.

The main difference is the high temperature and humidity, which remain constant here.

But solving the problem is not difficult if you follow simple rules.

Seals must be laid on the wall as tightly as possible.

This will avoid the appearance of cracks and cracks through which hot or cold air passes inside.

There will be less chance that excessive moisture and condensation will appear in the bathhouse.

Drying of the insulation is ensured only by ventilation gaps, so it is not recommended to forget about them.

Ceilings must withstand the highest temperatures, this is always worth remembering. The main thing is not to use materials that are too easily deformed for insulation in this part of the room.

Or those varieties that emit harmful chemical substances when they are exposed to high temperatures. Condensation collects on plastic without any problems.

Doors and thresholds in a room also affect thermal insulation performance. A large gap under the door can lead to a low heat capacity of the steam room. There is always a solution - it is enough to install low doors that have a large threshold.

Insulating a steam room from the inside yourself

The bathhouse helps us relax not only with our bodies, but also with our souls. Therefore, it is important that finishing materials not only fulfill their direct function, but also

Insulating a bathhouse - what you need for work

Insulating a bathhouse from the inside with your own hands will save money on work and heating. There is no shame in inviting friends to a comfortable bathhouse that exudes warmth and coziness. High-quality thermal insulation, competently made from good materials, can maintain a unique microclimate. The work is labor-intensive, but anyone with the necessary knowledge and skillful hands can handle it.

Insulating a bathhouse from the inside differs from thermal insulation work in ordinary premises due to the conditions in which the materials are exposed. First of all, this is humidity, especially in the steam room and washing room, and in other rooms the air is not dry. Therefore, the insulation either should not absorb moisture, or it must be reliably protected from steam and moisture. In the steam room, the temperature can even rise above 100°. Materials such as polystyrene foam and polystyrene foam are deformed at high temperatures and release substances harmful to health. For the same reason, plastic or linoleum is never used in the bathhouse. Some of the heat is lost as infrared radiation, so a foil layer is needed to reflect the rays.

To insulate a bathhouse, you will definitely need a foil heat-resistant hydro-vapor barrier.

In addition to the heat insulator, other materials will be required, in particular, sheathing. For stone brick baths It is better to use a profile for drywall. The ceiling profile CD is usually used, the UD guide is used for edging around the perimeter. The hangers are attached on average every 0.7 m, the distance between the profiles is slightly less than the width of the insulation. In a wooden bathhouse, instead of a plasterboard profile, it is advisable to use bars; they are cheaper and will last as long as the walls.

You will need a foil heat-resistant water vapor barrier. for example, penotherm. It is able to protect walls from dampness, reflect infrared rays, and additionally insulate the room due to the presence of foam material. For wooden baths it can be used as the main material for insulation. On top of the insulating layer they arrange finishing from the lining. The best material Linden or aspen are considered, they are durable even in such difficult conditions, and they do not burn.

How to insulate - a review of artificial and natural materials

When choosing a material for insulation, you should be guided by quality characteristics. A good insulation should provide reliable vapor and waterproofing, be environmentally friendly, and not fire hazardous. There are many materials for insulation - artificial and traditional from natural raw materials. If you are a fan of absolute environmental friendliness, then, of course, choose natural material. But you should know that without pre-treatment, such material is seriously threatened by mold, rodents, and insects. Artificial materials have better qualities and are easier to work with.

Natural materials for insulation, such as moss, flax tow, and hemp, have been used since ancient times. They are cheap or completely free, highly environmentally friendly, and fill the bathhouse with a special natural aroma. But they are short-lived, require constant updating, and working with them is difficult and time-consuming. Of the natural materials, perhaps expanded clay is the only one that is easy to work with and durable. It is moisture resistant, lightweight, and durable. Thanks to these qualities, expanded clay is used for floor insulation in bathhouses.

Synthetic materials for insulating a bathhouse from the inside include extruded polystyrene foam, mineral wool and glass wool. Each material has unique properties:

- 1. Expanded polystyrene is a reliable heat insulator of low cost and light weight. It is fire hazardous and cannot withstand high temperatures, so it is used only in the dressing room and other similar rooms, except for the washroom and steam room.

- 2. Mineral wool is a durable, fireproof, non-hygroscopic material. Available in the form of sheets or mats, which are convenient to work with. It is easy to damage, so you should work with mineral wool carefully.

- 3. Glass wool is made from interwoven extremely fine glass fibers. The material contains a lot of air, due to which it has a heat-saving effect. Available in rolls or slabs.

- 4. Basalt fiber is expensive, but it can be an ideal material for insulating a bathhouse. The basis is molten rocks, so the insulation does not burn, is not afraid of mechanical deformation and moisture, and retains heat well. It is convenient to work with it, cutting it into pieces of the required size.

The choice is influenced by the material of the walls. If the bathhouse is made of brick, stone, concrete and similar materials, it is necessary to insulate it. This is necessary to retain heat and extend the life of the building, because the walls will begin to collapse due to high humidity and very large temperature fluctuations. A wooden bathhouse itself is warm, but the insulation layer will not make it any worse. It is recommended to insulate log bathhouses with a wall thickness of less than 20 cm if the timber is less than 15 cm thick. If the log walls are thicker, thermal insulation for the bathhouse is not needed, or a waterproofing layer is used, which is then covered with clapboard.

To prevent your feet from freezing - warm floor without heating